Differential pressure transmitters are widely used in process industries to measure pressure, flow, and level. In flow measurement, differential pressure (DP) transmitters are used to measure the pressure difference across a restriction, such as an orifice plate or Venturi tube.

Differential pressure transmitters are widely used in process industries to measure pressure, flow, and level. In flow measurement, differential pressure (DP) transmitters are used to measure the pressure difference across a restriction, such as an orifice plate or Venturi tube.

In flow applications, both sides of the transmitter are exposed to the process pressure, often called line or static pressure, while the actual differential pressure depends on the flow rate. In many oil and gas custody transfer applications, the line pressure can be very high, while the differential pressure being measured may be relatively small.

In on-site conditions, these differential pressure transmitters are normally calibrated without line pressure for practical reasons. However, this can introduce small errors compared to how they behave when operating with line pressure in the process. To eliminate this error, the footprinting method can be used.

In this blog, we’ll take a closer look at what happens when a DP transmitter operates under high line pressure, how this can influence calibration results, what the footprinting method is, and how it helps ensure accuracy in the field.

Table of contents

- What is a differential pressure transmitter?

- Line pressure effects – a source of error

- Calibration in the field – the practical reality

- Making the footprint – characterizing the transmitter in the lab

- Using the footprint in field calibration

- Calibration challenges

- Other considerations

- Summary – Why footprinting matters

- The Beamex solution – putting footprinting into practice

- Want to discuss your pressure calibration practices?

- Learn more about pressure calibration

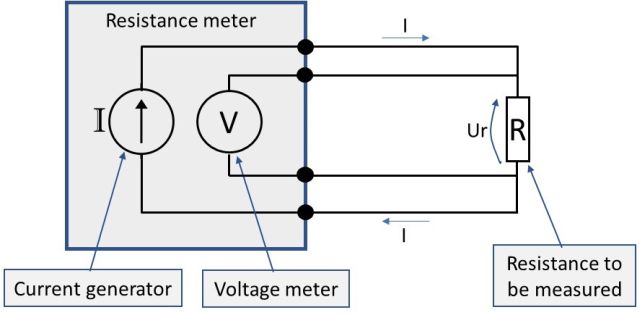

What is a differential pressure transmitter?

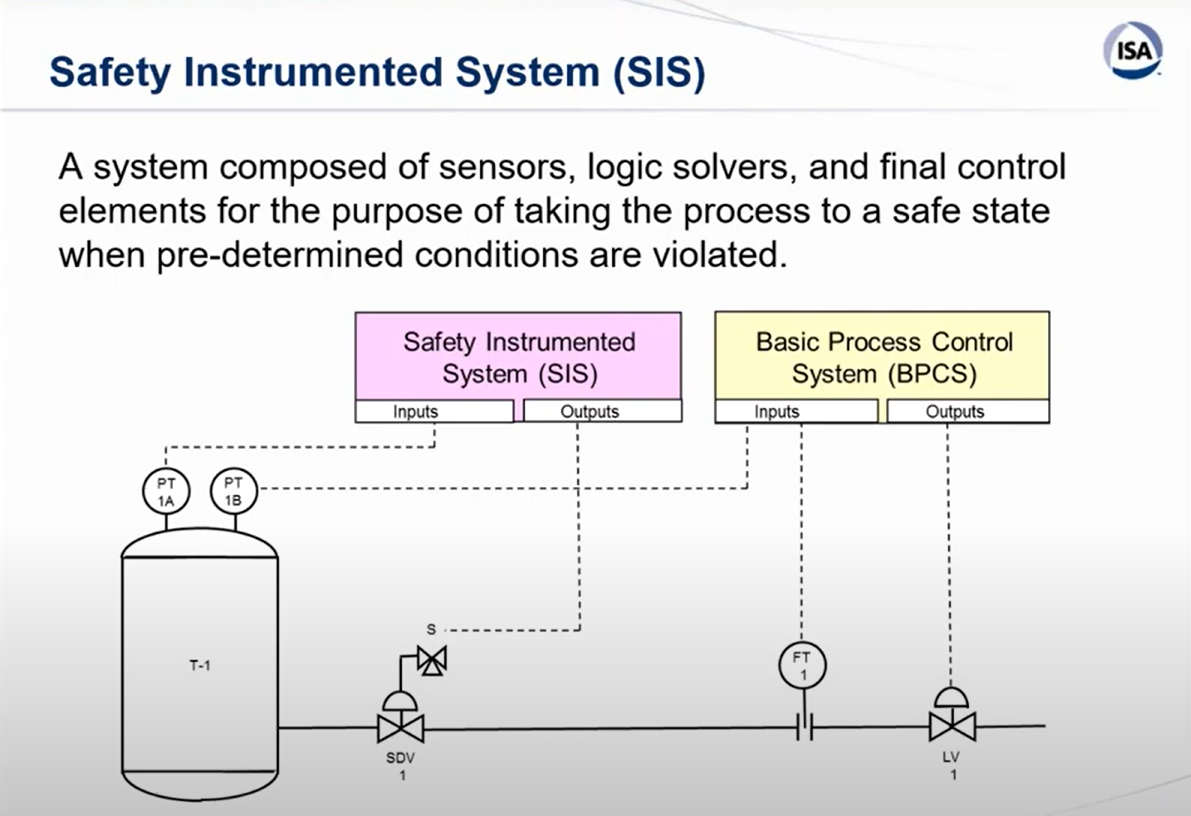

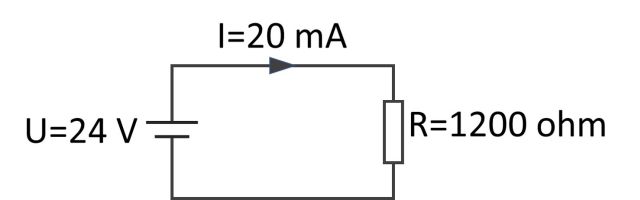

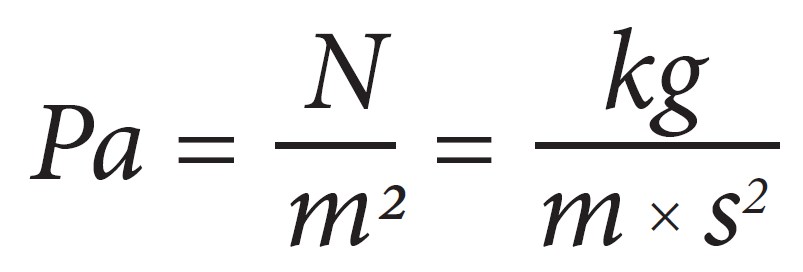

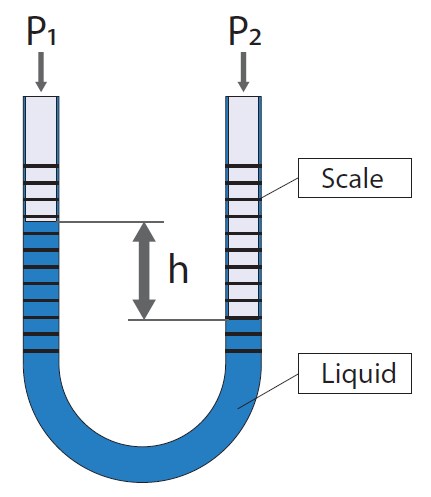

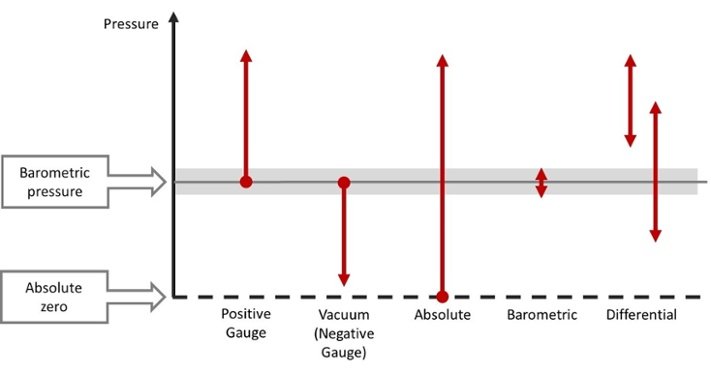

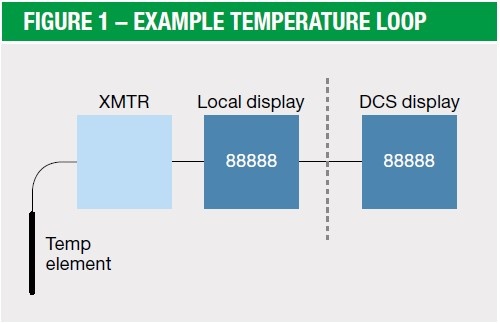

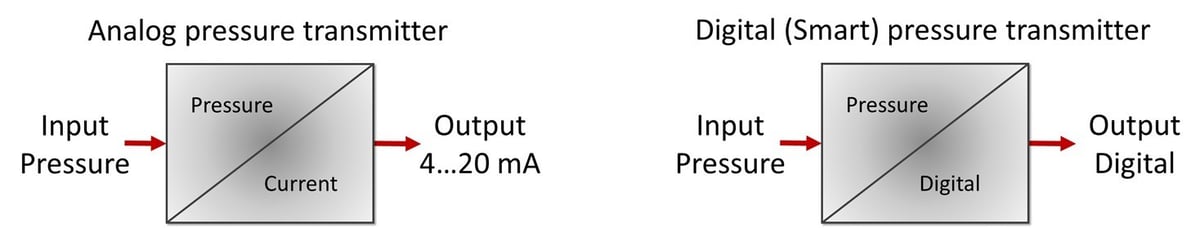

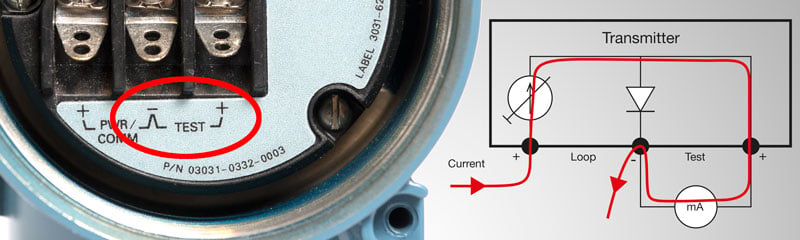

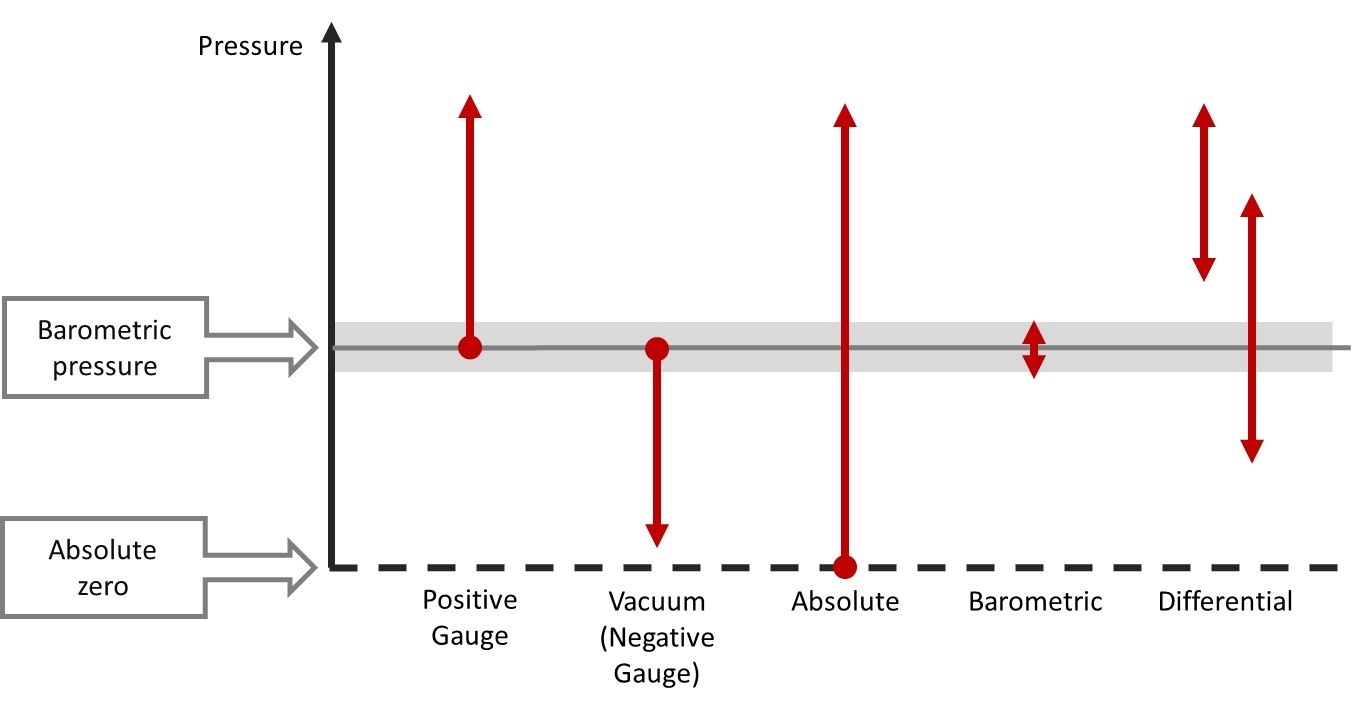

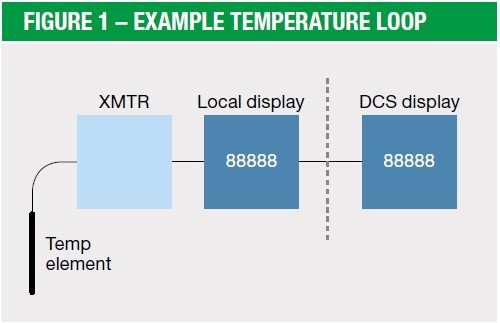

A differential pressure (DP) transmitter measures the difference between two pressure points, commonly referred to as the high-pressure (HP) side and the low-pressure (LP) side. The transmitter converts this pressure difference into an electrical mA signal (or digital signal such as HART or Fieldbus) that represents a process variable such as flow, level, or pressure.

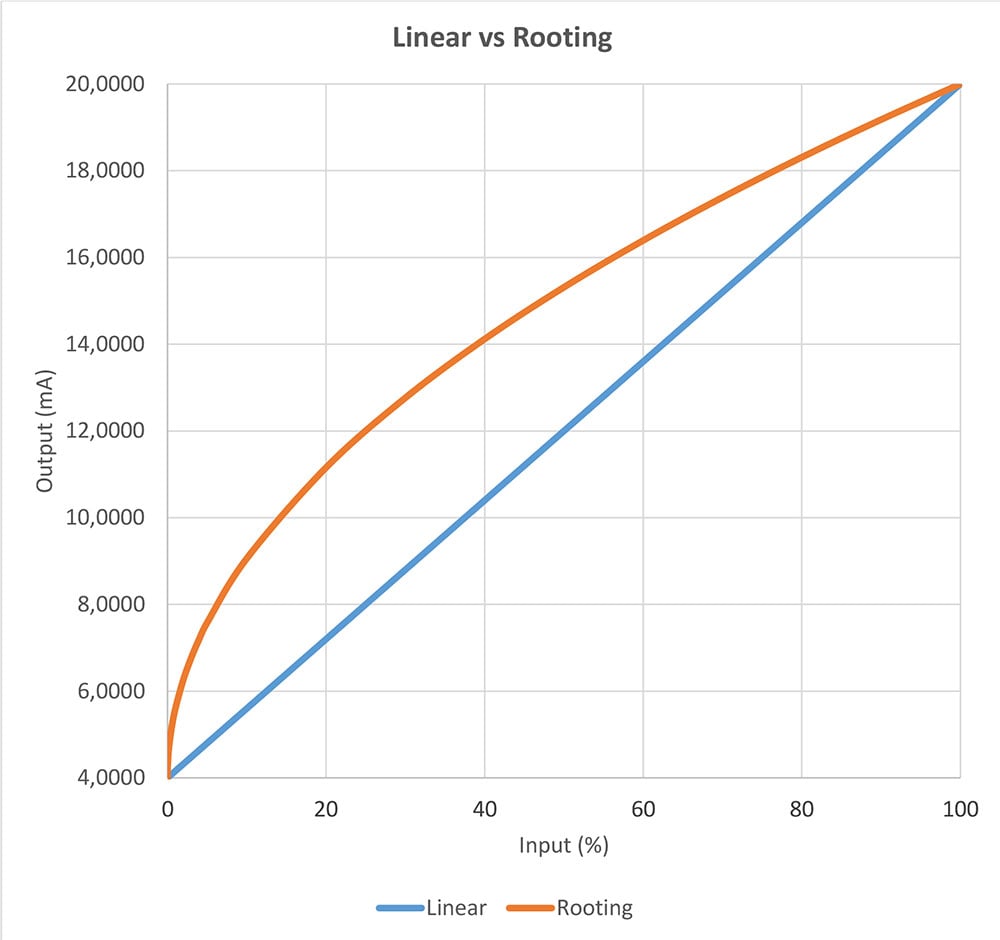

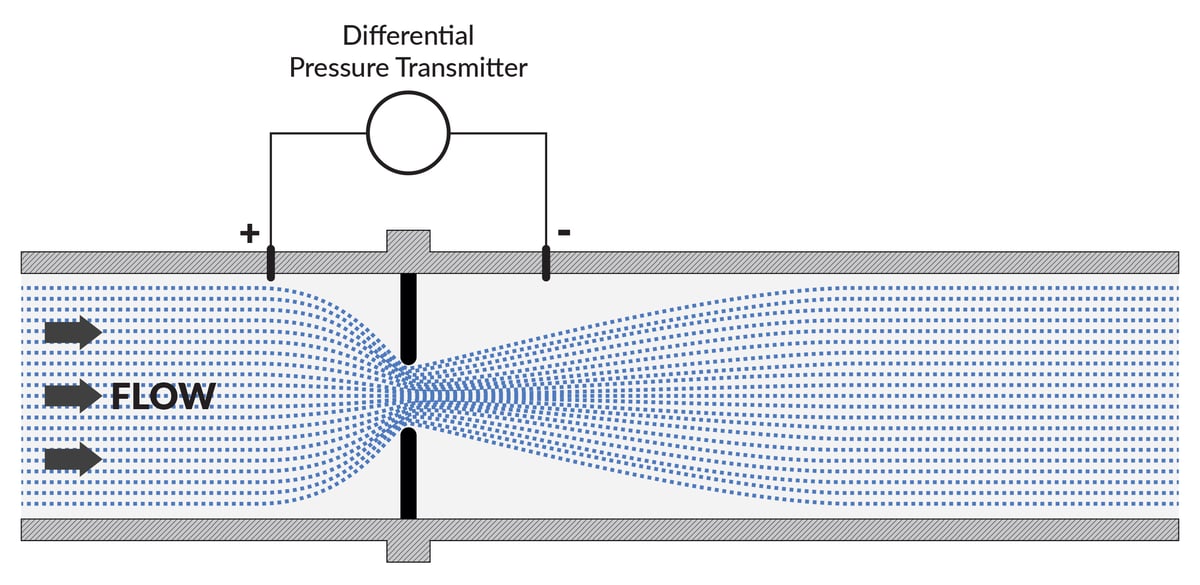

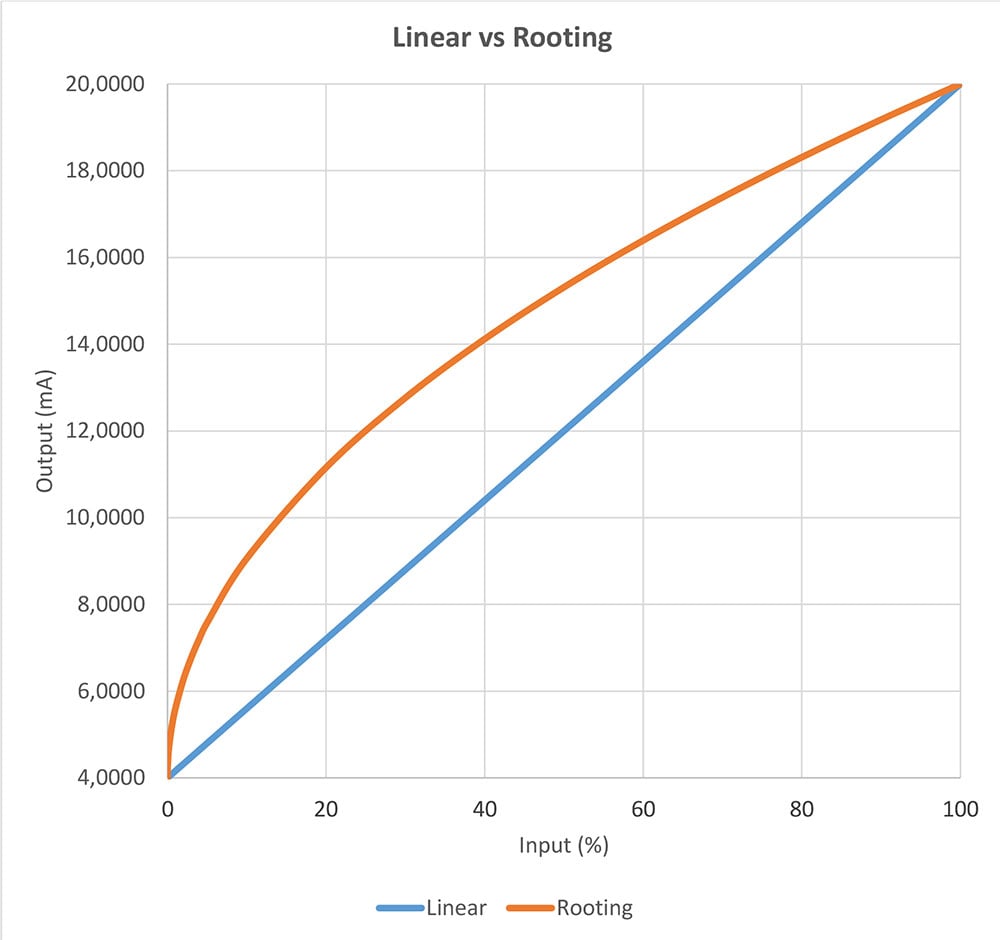

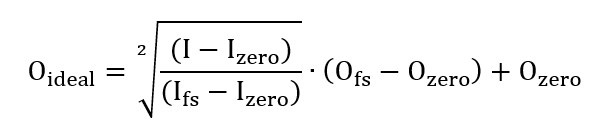

In flow measurement, the transmitter is connected across a primary element such as an orifice plate, Venturi tube, or flow nozzle. These primary elements create a pressure drop that increases with flow rate. The DP transmitter senses that differential pressure, and since flow is proportional to the square root of the differential pressure, the signal can be used to calculate the flow.

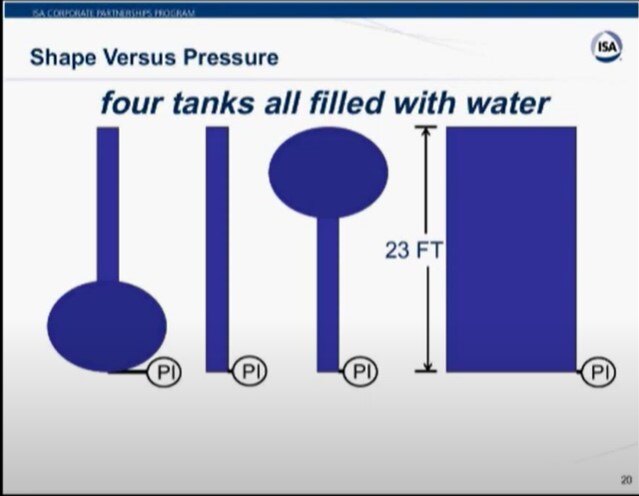

A DP transmitter can also be used for level measurement, for example in a closed or pressurized tank where it measures the hydrostatic pressure difference between the top and bottom of the tank. In this article we will focus on flow measurement, which is one of the most common uses of DP transmitters.

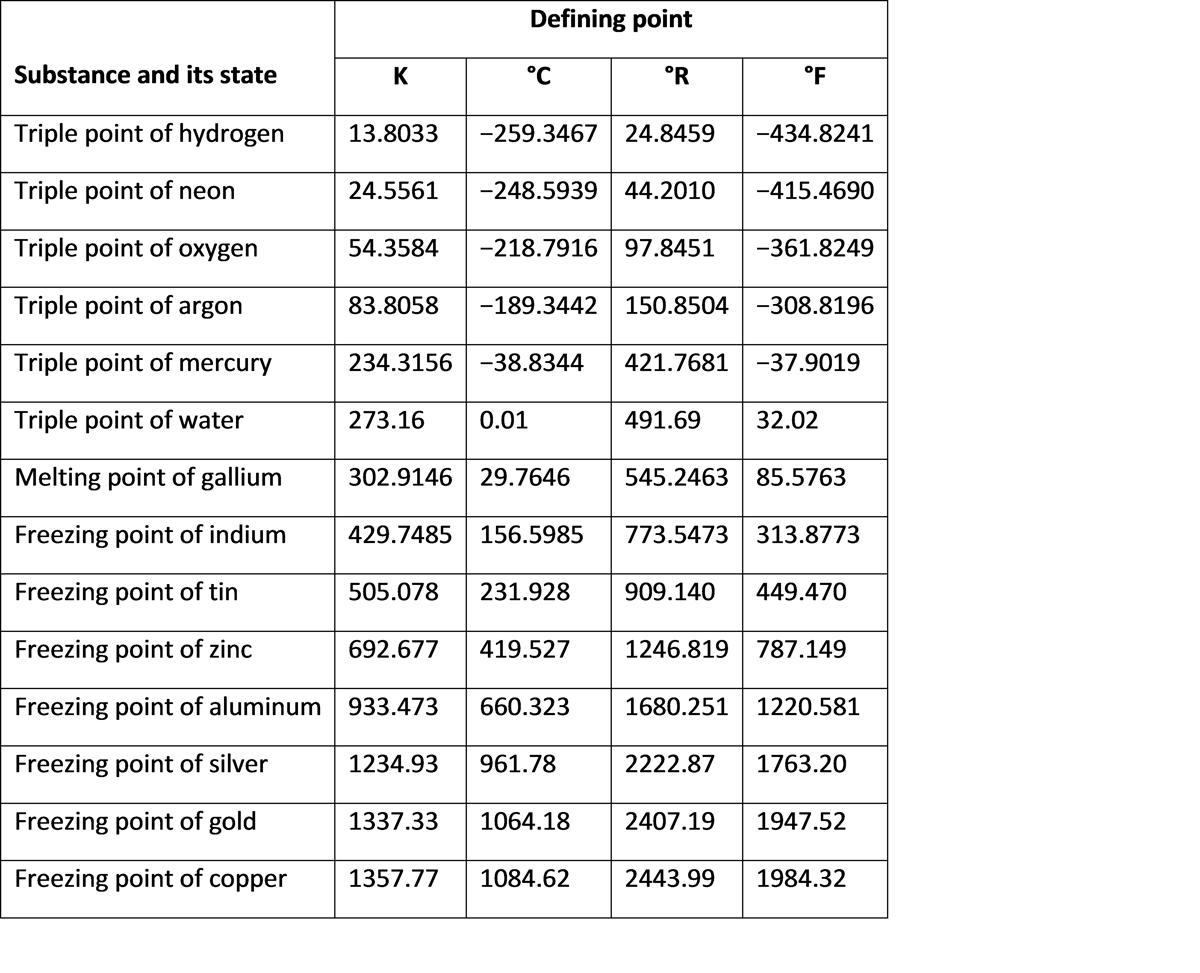

In many industrial flow applications, both sides of the transmitter are exposed to the process line pressure, often called static pressure. The line pressure can be tens of bars, or up to around 100 bar (1,450 psi), or even over 200 bars (2,900 psi), while the actual differential pressure being measured may be from tens of millibars to a few hundred millibars (tens to hundreds inH2O), or even up to 5 bars (2,000 inH2O).

The most extreme oil and gas subsea applications today may have a line pressure of over 1,000 bar (14,500 psi)!

The combination of high static pressure and relatively small differential pressure is typical in oil and gas, refining, and power generation applications. The accuracy is most critical in the custody measurements. It is also what makes the calibration of these transmitters more challenging and the concept of footprinting so important.

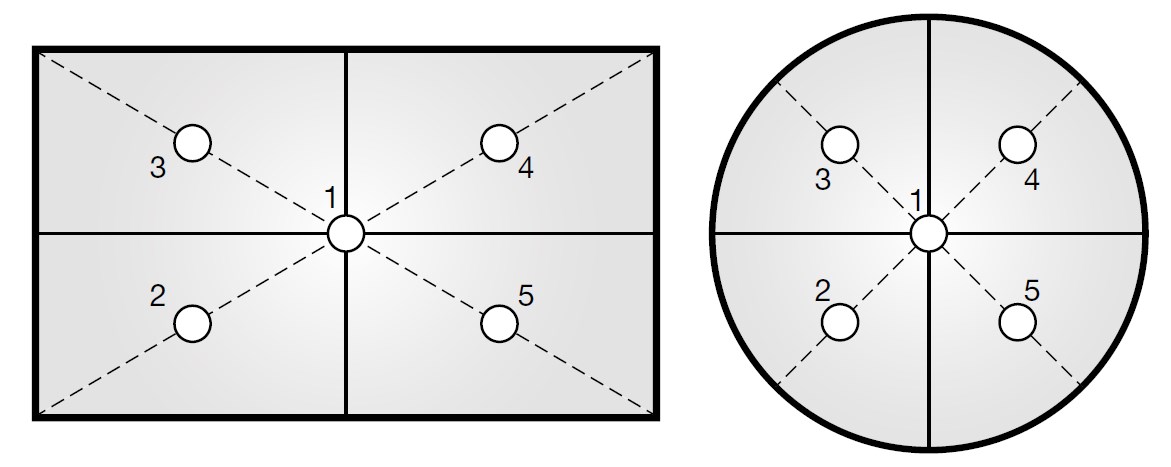

This above diagram shows how a differential pressure transmitter is used for flow measurement with an orifice plate. The restriction causes the flow to accelerate and the static pressure to drop downstream of the orifice. By measuring the upstream pressure at the high-pressure tap (+) and the downstream pressure at the low-pressure tap (–), the transmitter produces a differential pressure signal. The magnitude of this pressure drop is related to the flow rate through the pipe according to the square-root relationship.

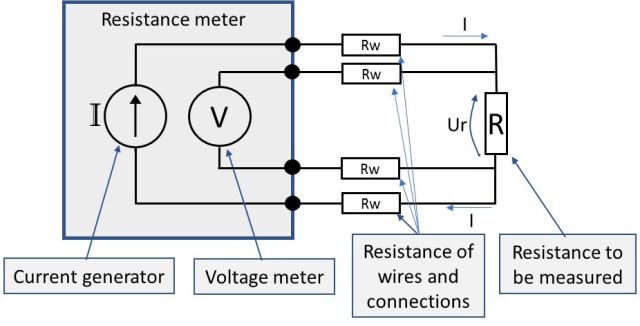

Line pressure effects – a source of error

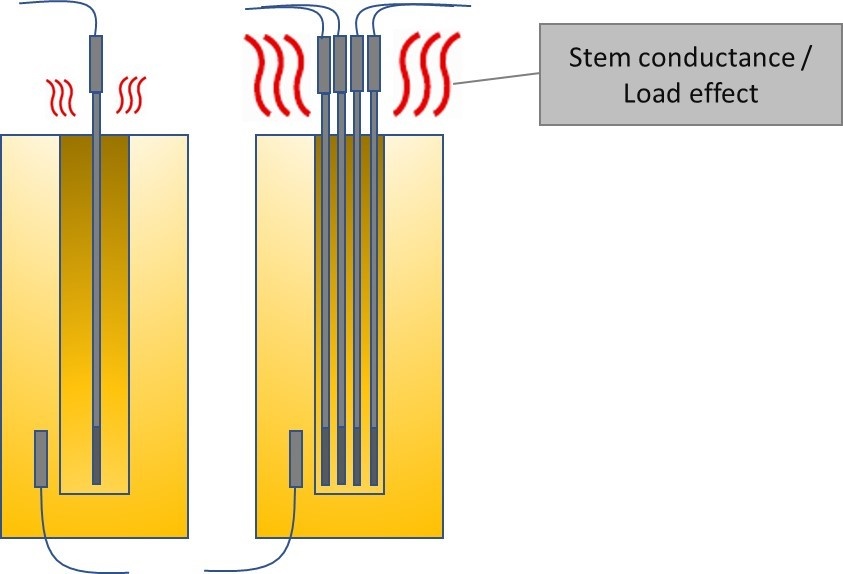

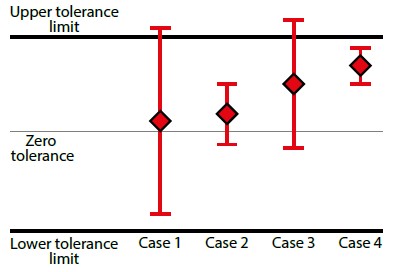

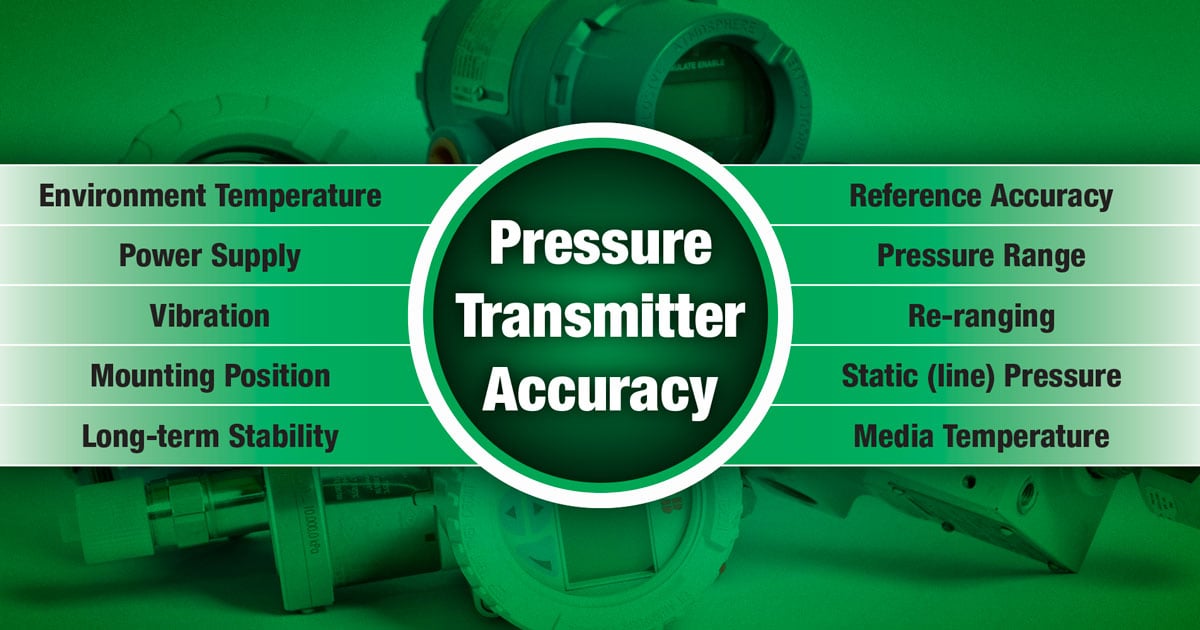

Even though a differential pressure transmitter is designed to measure the difference between two pressures under different static pressures, the static (line) pressure acting equally on both sides can still influence the measurement. Commonly, the higher the line pressure, the more it will affect the measurement.

This happens because the transmitter’s sensing diaphragms, fill fluid, and internal mechanical structure are exposed to the line pressure. When the line pressure increases, the diaphragms and internal components deform slightly, even if the differential pressure remains the same. That small deformation can cause a shift in the transmitter’s output.

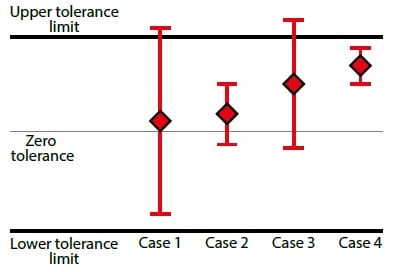

In practical terms, this means that a DP transmitter that measures accurately when tested at atmospheric pressure may have error when the differential pressure is applied under a high line pressure. The difference might be significant, and in high-accuracy fiscal flow measurement this is critical.

The amount and direction of this shift depend on the transmitter design, materials, range, and even the fill fluid used inside the sensing modules. Some transmitters are also more sensitive to static pressure than others.

For example, under a line pressure of 100 bar (1,450 psi), a DP transmitter might show a small zero shift or a slight span change compared to its calibration at atmospheric conditions. When that transmitter is later used in a process where the line pressure constantly varies, the static pressure effect can appear as a small but consistent measurement error.

That’s why it’s important to understand how a particular transmitter behaves under both conditions, with and without line pressure. This is where the concept of footprinting becomes valuable, as it allows you to characterize and later compensate for this effect.

Calibration in the field – the practical reality

In an ideal world, calibration would always be performed under the same conditions in which the transmitter operates. For a differential pressure transmitter used in a process with varying high line pressure, that would mean applying both line pressure and differential pressure during calibration.

In practice, this is rarely possible in the field. Most portable pressure calibrators are not designed to handle the full process line pressure on both sides of the transmitter at the same time. To generate both the static and differential pressure simultaneously, a differential deadweight tester is typically required. Such equipment is large, heavy, and not suitable for field use, especially in demanding environments like offshore oil and gas platforms.

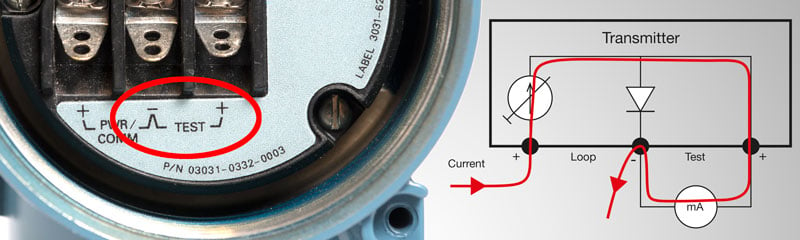

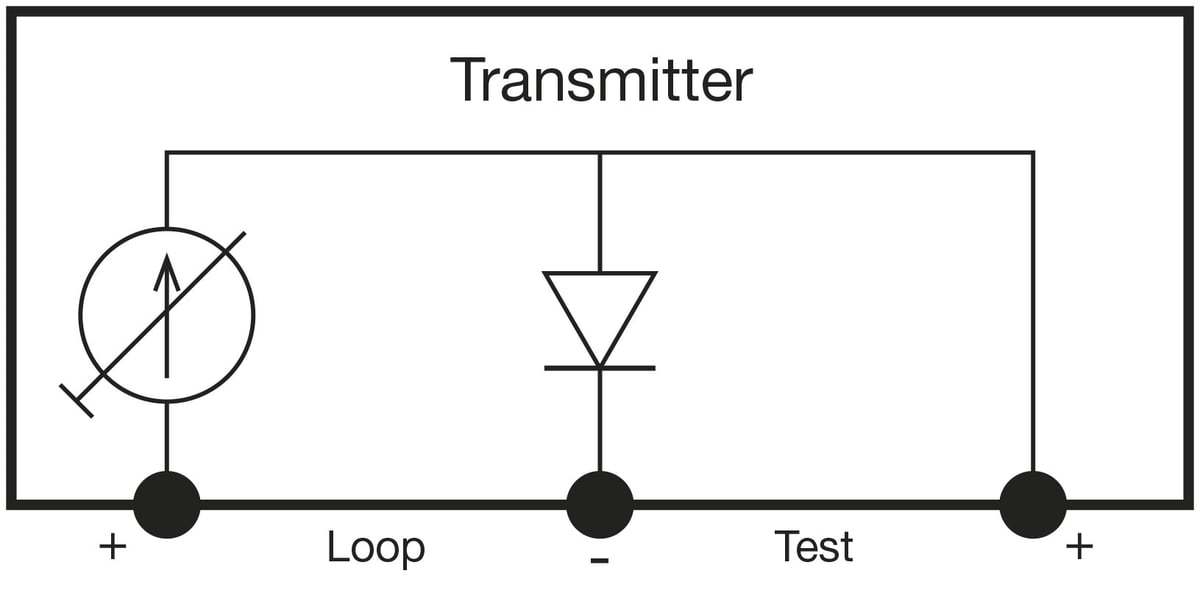

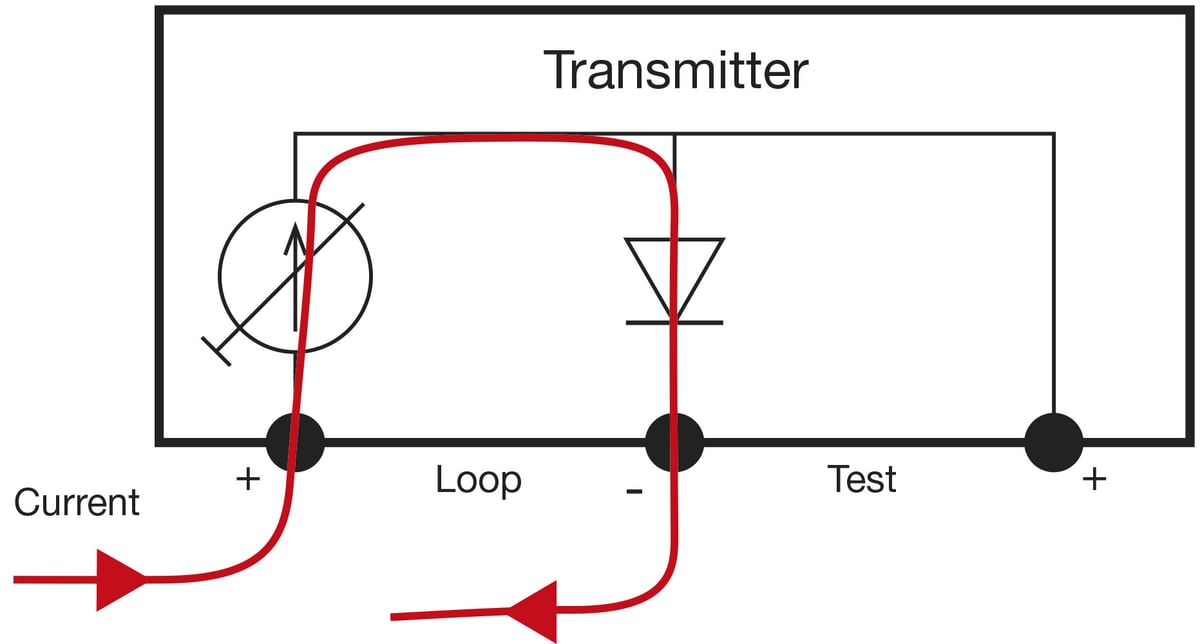

Because of this, field calibration is almost always done without line pressure, meaning the negative side of the transmitter is vented to the atmosphere while pressure is applied to the positive side to generate the desired differential pressure.

This method is practical, safe, and fast – and for many applications it provides results that are accurate enough. However, for transmitters operating under high static pressure, it can lead to small differences between the calibration performed in the field and the transmitter’s actual behavior in the process.

As we saw earlier, static pressure can cause small shifts in the transmitter’s output. So, when you calibrate it at zero line pressure, you’re not reproducing the real process conditions. The result is that the transmitter may appear accurate during calibration, but it could have error once installed and pressurized in the process.

That’s why it is useful to understand how the transmitter behaves under both conditions. This understanding is gained through footprinting, which provides a reference that allows field calibration without line pressure to produce accurate results under real operating pressure.

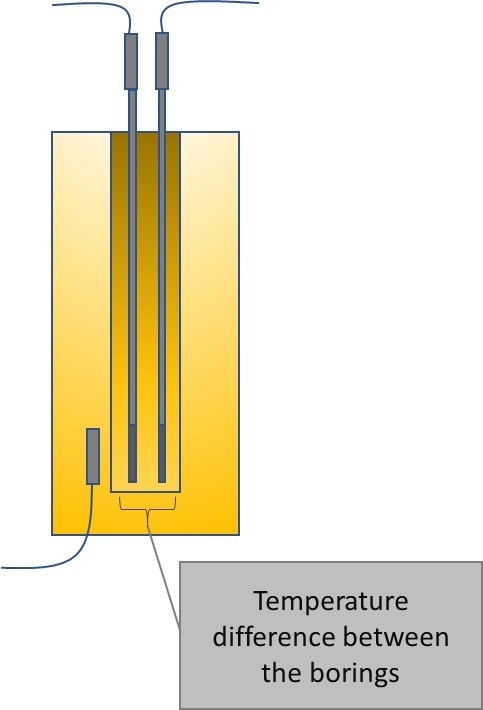

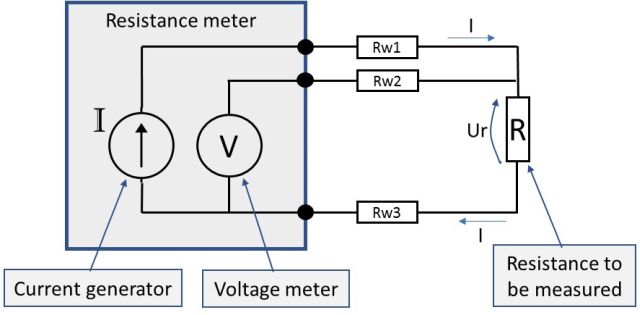

Making the footprint – characterizing the transmitter in the lab

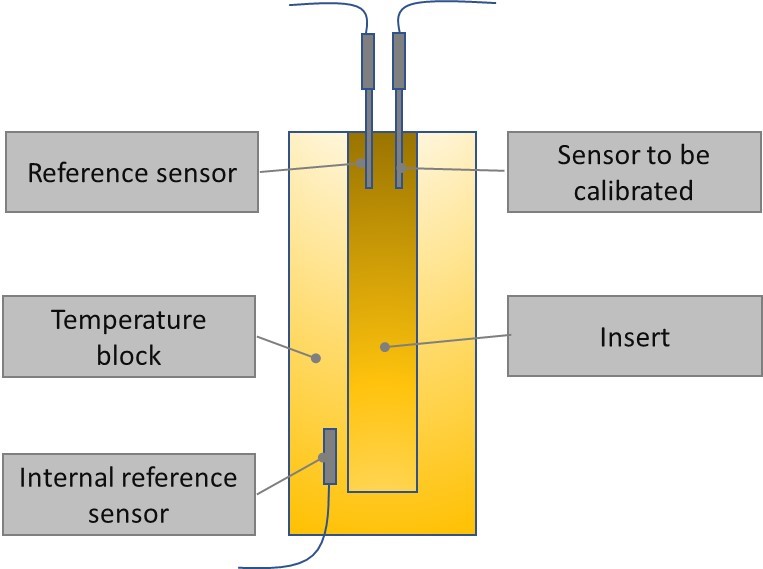

To understand how a differential pressure transmitter behaves under line pressure, it needs to be tested in controlled laboratory conditions.

The goal of this testing is to determine how the transmitter’s output changes when exposed to high static (line) pressure compared to calibration at atmospheric pressure. In other words, this testing tells you how the transmitter “behaves” under real process conditions.

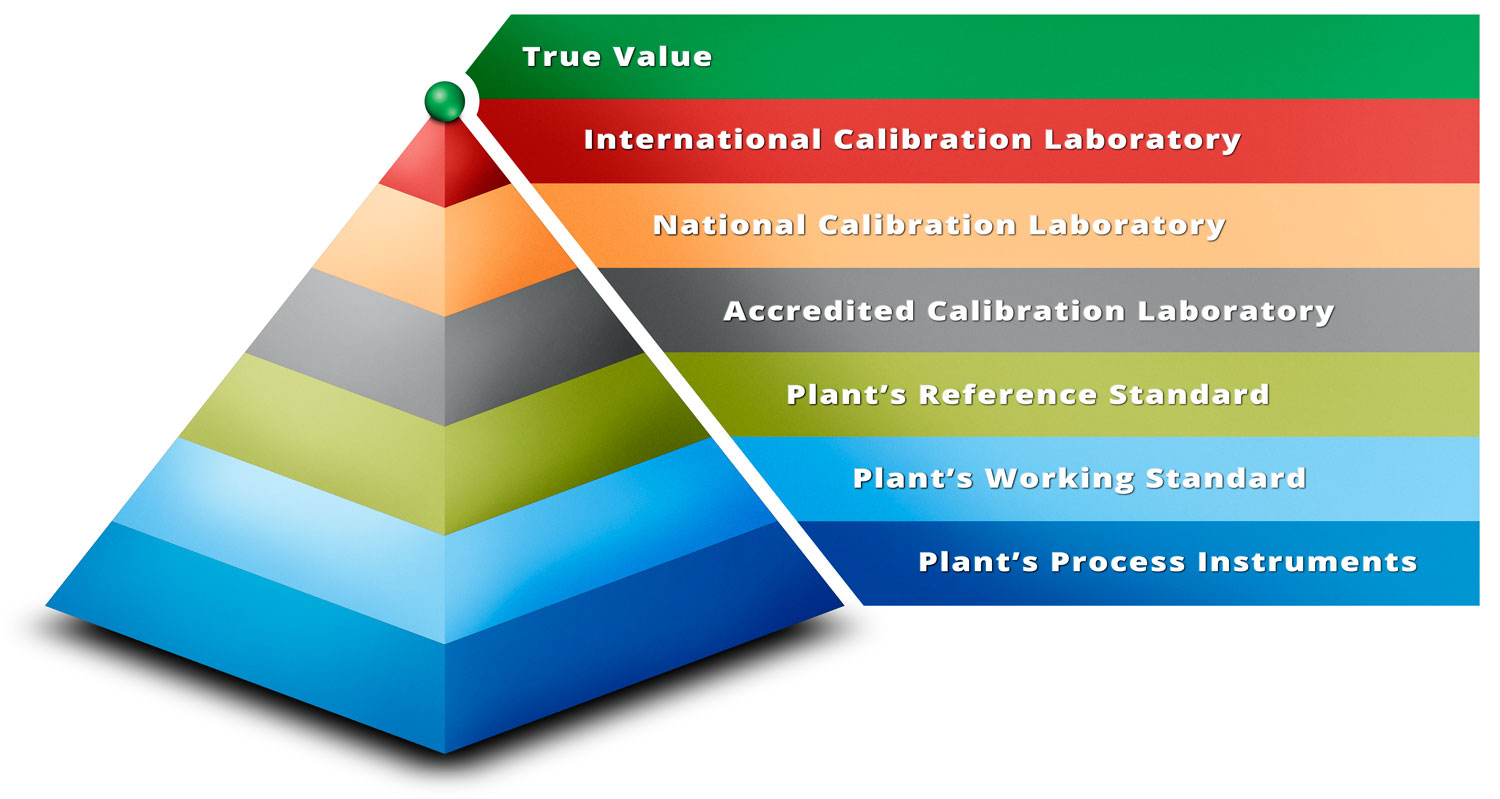

This is normally done in an accredited calibration laboratory equipped with an accurate differential deadweight tester or other high-accuracy setup capable of applying static pressure and differential pressure simultaneously. The deadweight tester allows precise control of the pressures on both sides of the transmitter, so the effect of static pressure can be measured accurately.

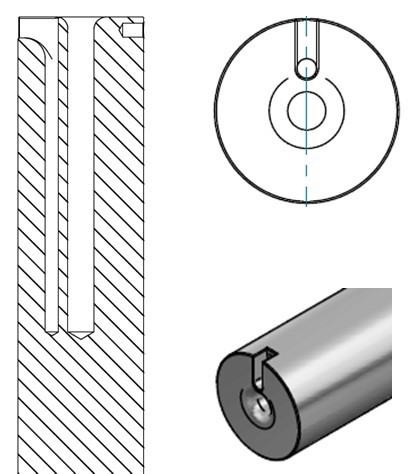

When a differential pressure transmitter is sent to a laboratory for footprinting, it is usually sent with its connection block or manifold attached. Removing and reinstalling the block can introduce a small effect on the calibration. Keeping the block in place ensures that the footprint reflects the transmitter’s actual installation and provides the best possible repeatability once it is returned to service.

The procedure usually includes these steps:

- Calibrate at zero line pressure – The transmitter is calibrated under normal lab conditions with the low side vented to the atmosphere. This establishes a baseline reference.

- Calibrate under line pressure – The same calibration is then repeated with a known static pressure applied equally to both sides of the transmitter, often matching the process line pressure. This may also be done at several different line pressures to see how the transmitter reacts across its expected operating range.

- Compare the results – The difference between the calibration results shows the transmitter’s static pressure effect.

From these results, the lab can see whether the line pressure affects the transmitter’s zero, span, or linearity – or sometimes all three.

For example, one transmitter may show a slight zero shift when static pressure is applied, while another might also show a span change. Each transmitter model tends to have its own “signature”, or footprint, of how it reacts to line pressure. According to some Beamex customers, even transmitters of the same make and model can behave differently.

Once this footprint is known, it becomes possible to predict how the transmitter will behave under operating conditions. This information can then be used later, during field calibration, to ensure that even a calibration done without line pressure will be accurate when the transmitter is reinstalled in the process.

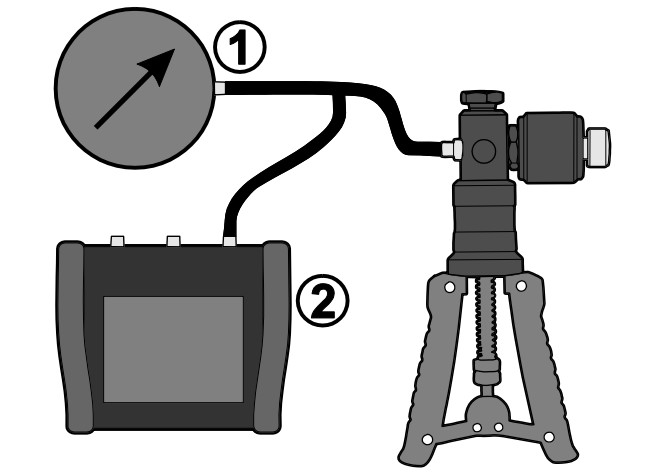

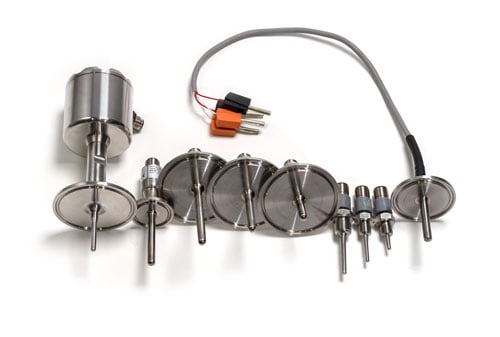

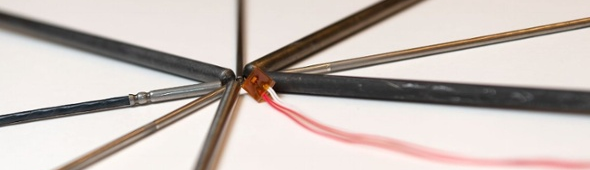

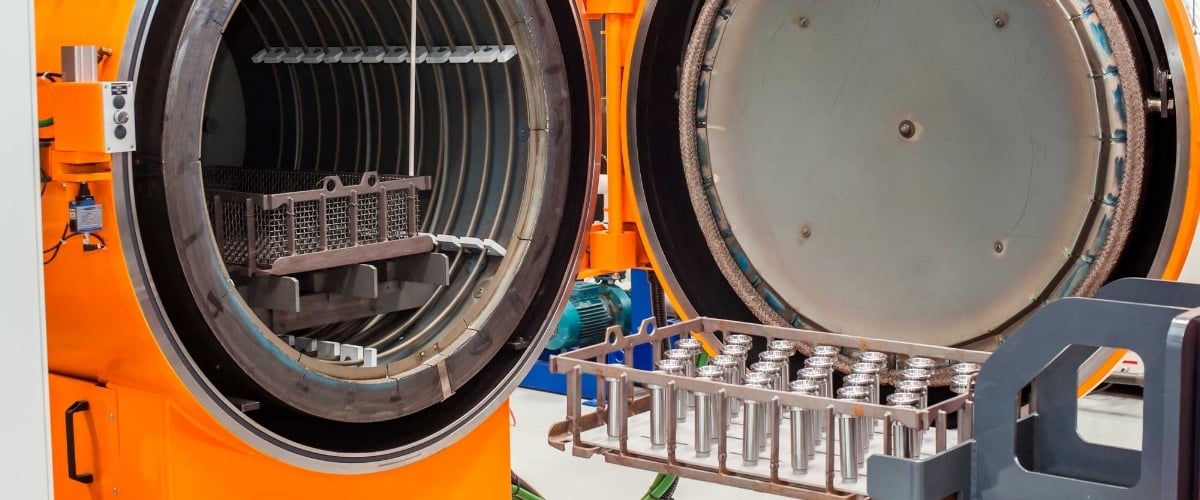

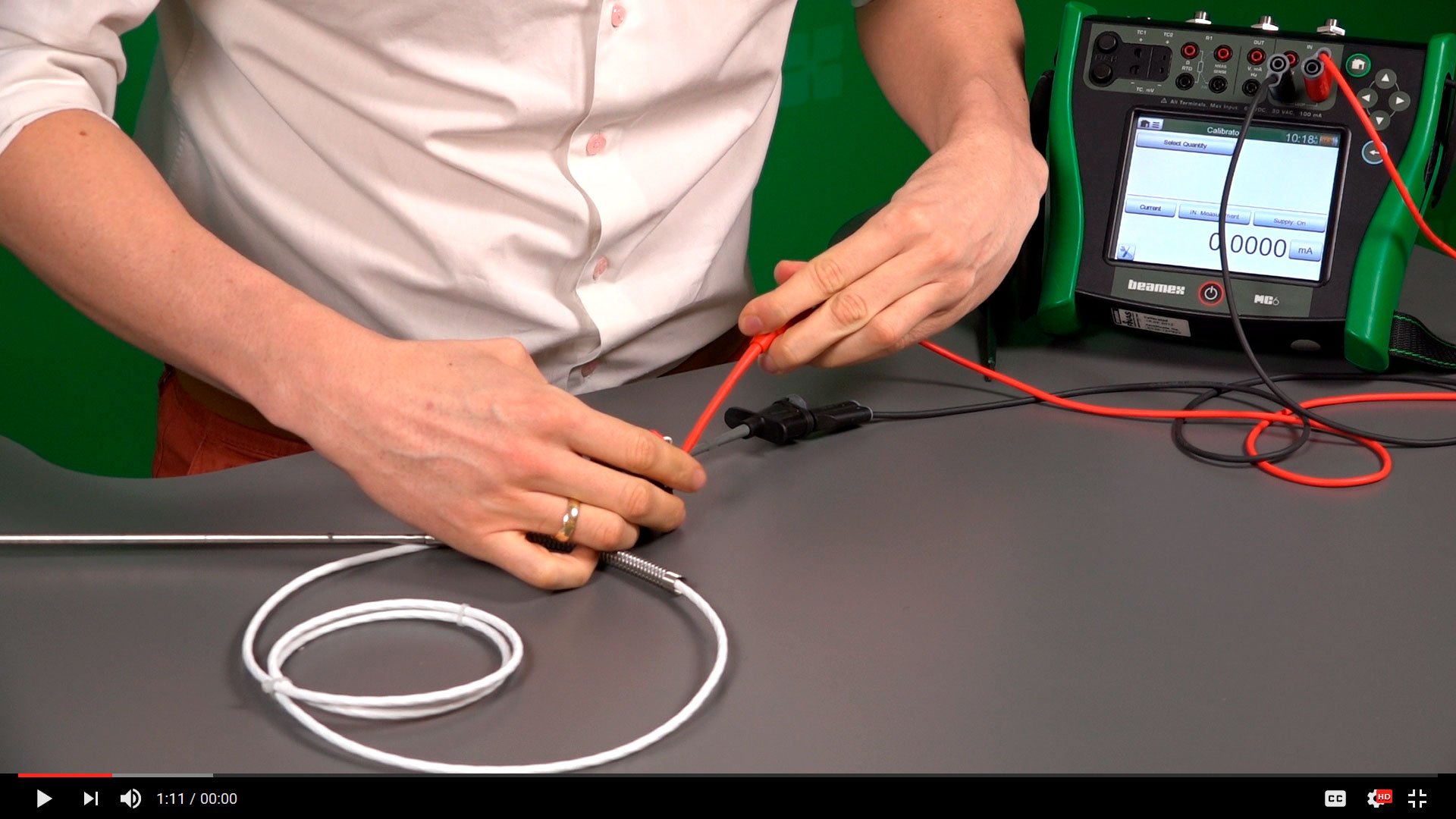

This photo shows a setup with a differential deadweight tester used to generate both the static pressure and the differential pressure needed to perform transmitter footprinting in a controlled environment.

Photo provided by Trescal Norway AS. Used with permission.

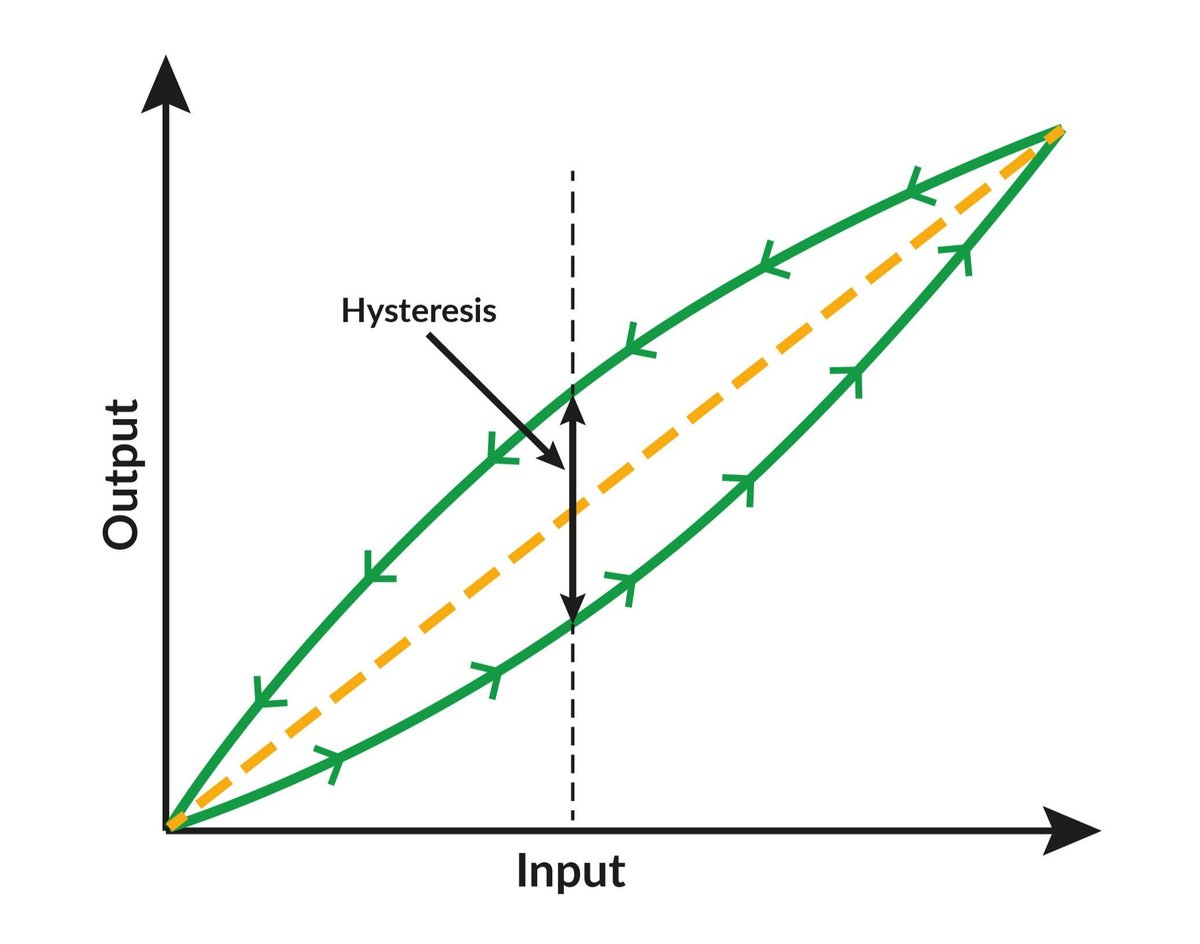

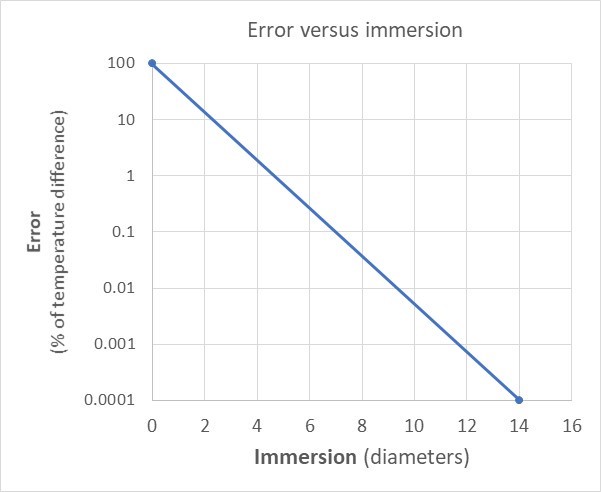

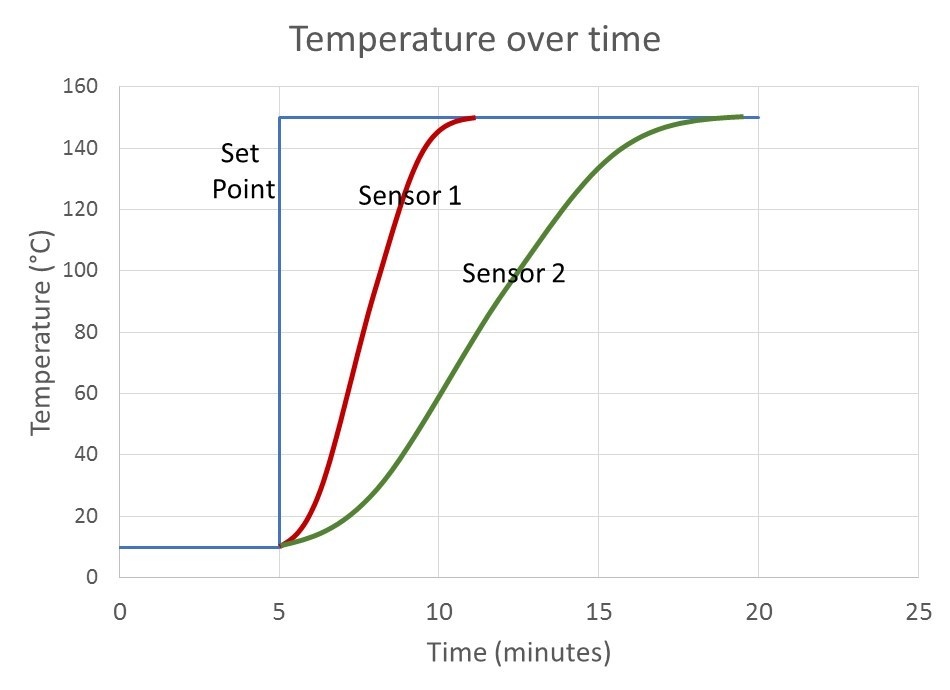

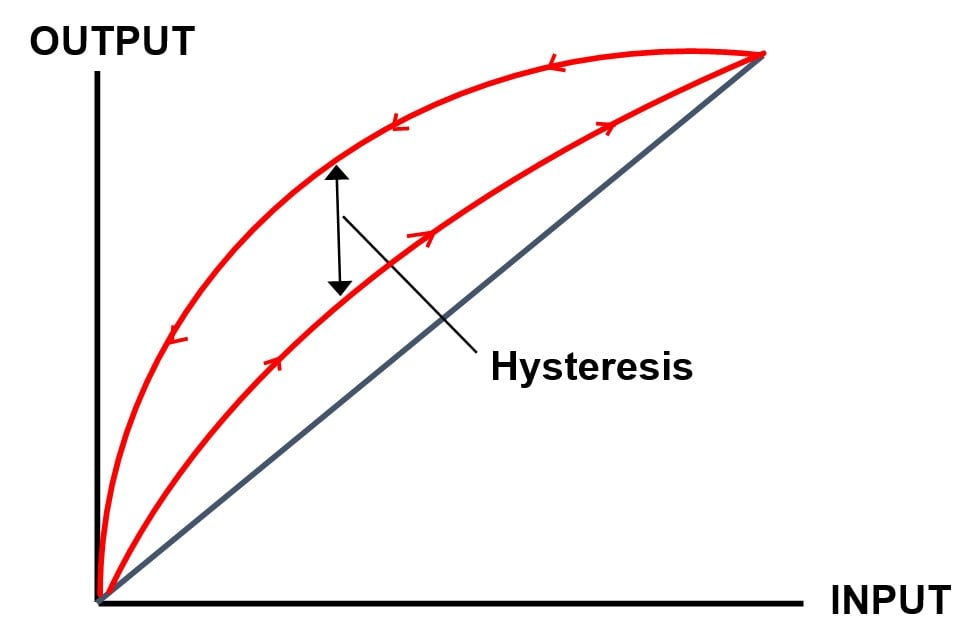

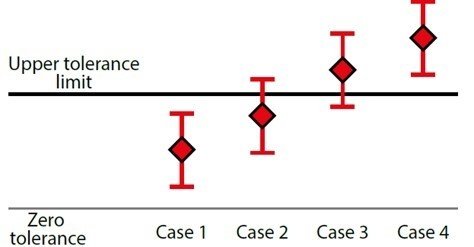

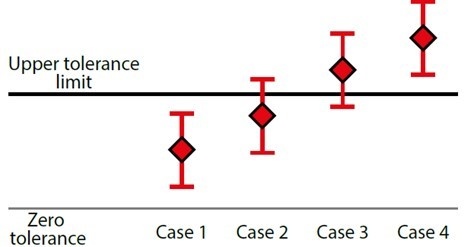

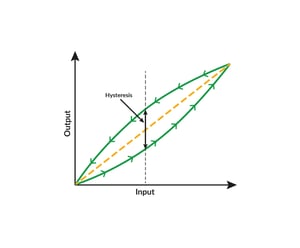

This above example illustrates how a differential pressure transmitter can behave differently when calibrated at atmospheric pressure compared to when the same differential pressure is applied under line pressure. The two curves show the deviation from the ideal value in each case. The difference between the two curves is the transmitter’s “footprint,” which needs to be taken into account when performing an on-site calibration without line pressure. In real life, there is typically also some hysteresis in the results, but for simplification that is not shown in this graphic.

This above example illustrates how a differential pressure transmitter can behave differently when calibrated at atmospheric pressure compared to when the same differential pressure is applied under line pressure. The two curves show the deviation from the ideal value in each case. The difference between the two curves is the transmitter’s “footprint,” which needs to be taken into account when performing an on-site calibration without line pressure. In real life, there is typically also some hysteresis in the results, but for simplification that is not shown in this graphic.

Using the footprint in field calibration

Once the transmitter’s behavior under line pressure is known from laboratory testing, this information can be used to improve the accuracy of field calibrations performed without line pressure. This is where the earlier laboratory testing becomes truly valuable.

The lab results reveal how the transmitter’s output changes when static pressure is applied. For example, it might show that under 100 bar (1,450 psi) of line pressure, the transmitter output shifts slightly upward, making it read a little higher than when tested at atmospheric pressure. Another transmitter model may show the opposite effect or a combination of zero and span changes.

When you know this behavior, you can use it to interpret and adjust field calibration results. In practice, this means that when calibrating the transmitter in the field, you intentionally adjust it to read a little bit differently from the “perfect” value under zero line pressure. That way, once the transmitter is installed and exposed to process line pressure, its reading will be accurate.

In other words, you adjust/calibrate it to be slightly “wrong” so that it becomes right in the process.

In some cases, you may even need to adjust the transmitter to be “out of spec” without line pressure, to ensure it will be accurate with line pressure.

For example, if the laboratory footprint shows that the transmitter reads 0.05% too high when under 100 bar (1,450 psi) of static pressure, the field calibration can be adjusted so that it reads 0.05% lower when calibrated without line pressure. After installation and pressurization, the transmitter will then read correctly under its operating conditions.

This method allows accurate and traceable calibration without having to reproduce high line pressures in the field. It also ensures consistency between lab and field calibrations and provides confidence that the transmitter’s process performance will match expectations.

Calibration challenges

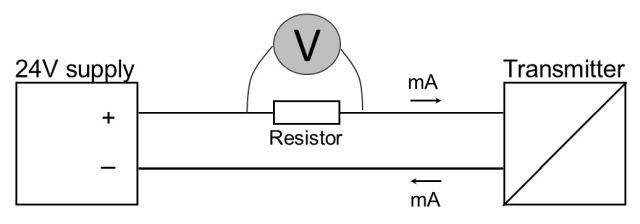

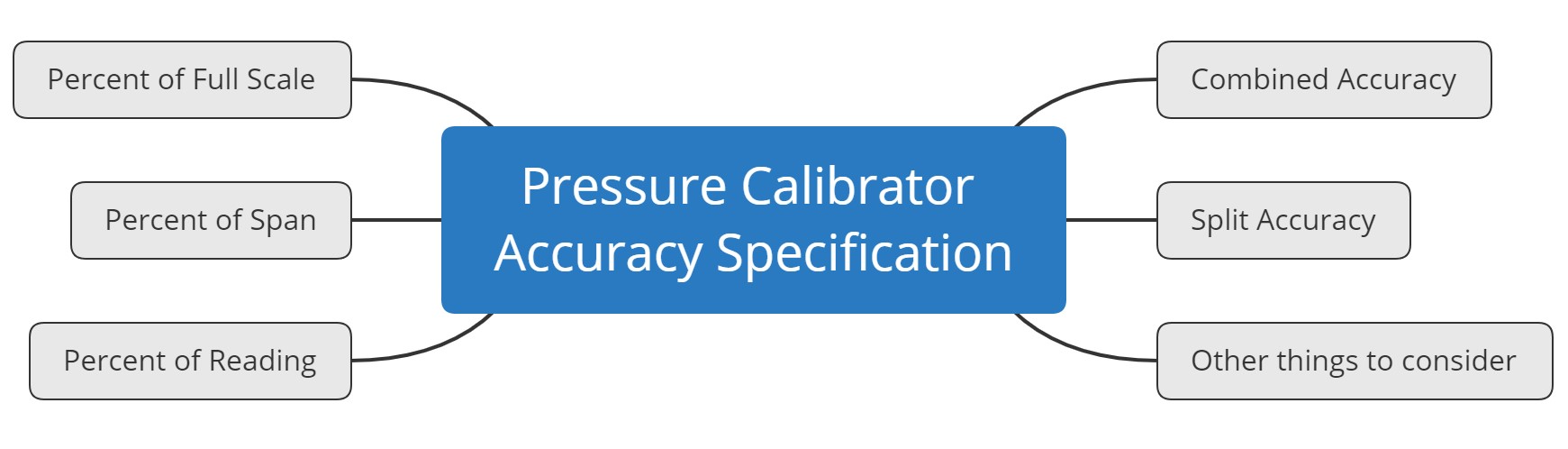

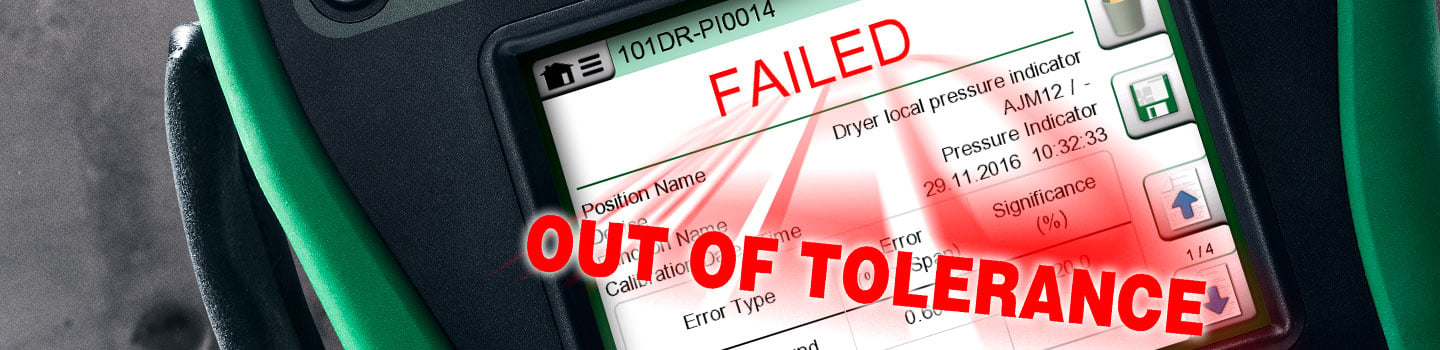

Once the transmitter’s footprint is known from laboratory testing, the next question is how to use that information in practice.

In theory, you could look up the footprint results from a paper report or spreadsheet and manually apply the necessary offsets during calibration. For example, if the footprint shows that at zero differential pressure the transmitter’s correct target output should be 4.020 mA, you would treat 4.020 mA as your target during field calibration.

However, in real life, this quickly becomes difficult and error prone. Technicians work under pressure, and manually adjusting for these small offsets is both inconvenient and risky. If you forget to apply the offset or calculate it incorrectly, the calibration result will no longer represent how the transmitter behaves under its actual operating conditions.

Another challenge is that transmitters may have different types of line pressure effects. For some, the effect is mainly a zero shift; for others, both zero and span will change, and sometimes linearity too. The required correction may also vary depending on the applied differential pressure. This means that a single static offset is not enough because the correct value may change from one calibration point to another.

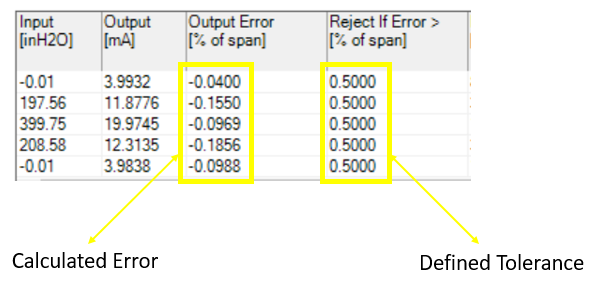

That is why your calibration solution needs to understand the footprint data and handle these offsets automatically. Ideally, both the calibration management software and the calibrator should know the transmitter’s expected behavior under line pressure so they can present the correct expected values and automatically calculate the error relative to those values, not to the “ideal” atmospheric-pressure values.

For example, when performing a field calibration at zero differential pressure, the calibrator might display that the expected value is 4.020 mA, not 4.000 mA. It will then calculate the error against 4.020 mA, since that is what the transmitter should produce once it is back in service under line pressure.

If your calibration tools do not support this functionality, the only alternative is manual work: reading the offset from a paper or spreadsheet and applying it yourself. That approach is slow, inconsistent, and prone to error, especially when there are multiple transmitters or complex footprints involved.

Automating this process not only saves time but also improves accuracy, consistency, and traceability. It ensures that the footprinting data collected in the lab can be used effectively in the field, turning theoretical understanding into practical calibration accuracy.

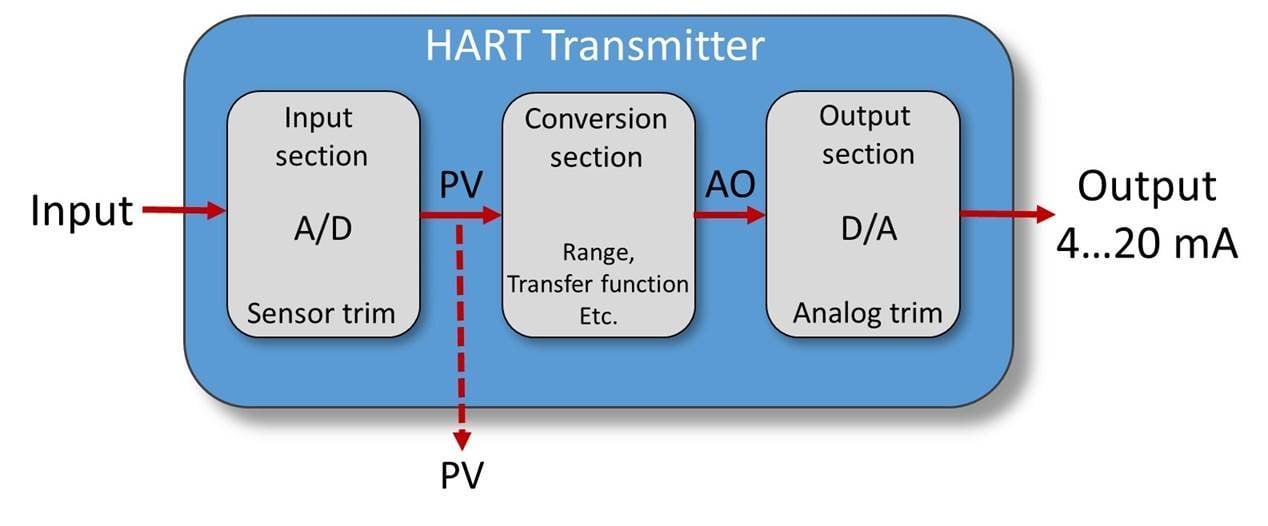

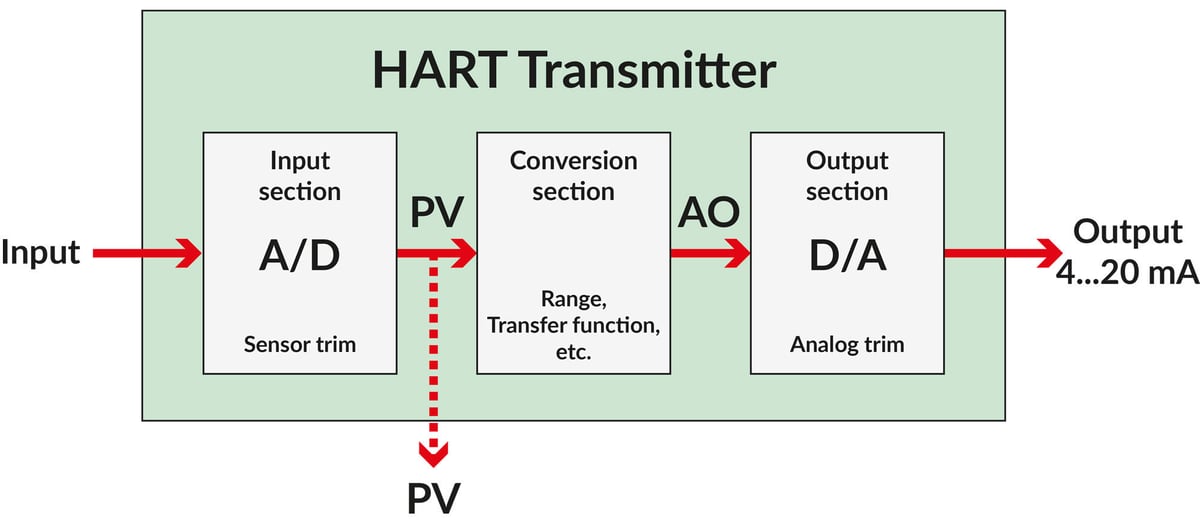

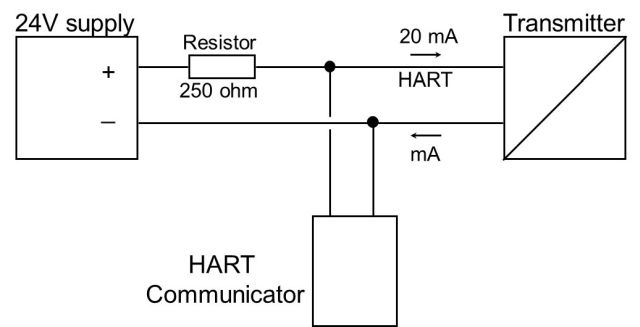

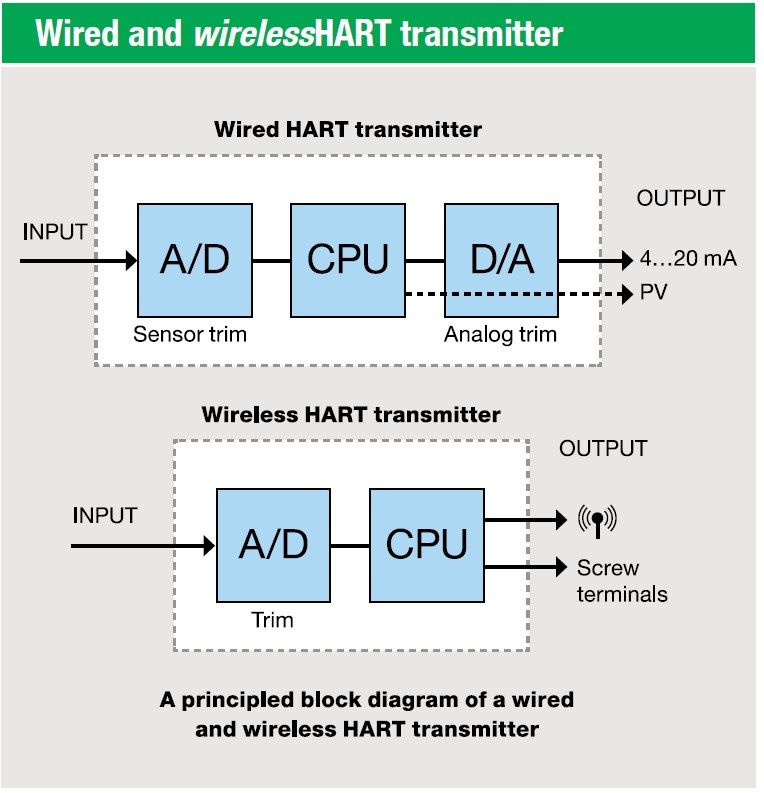

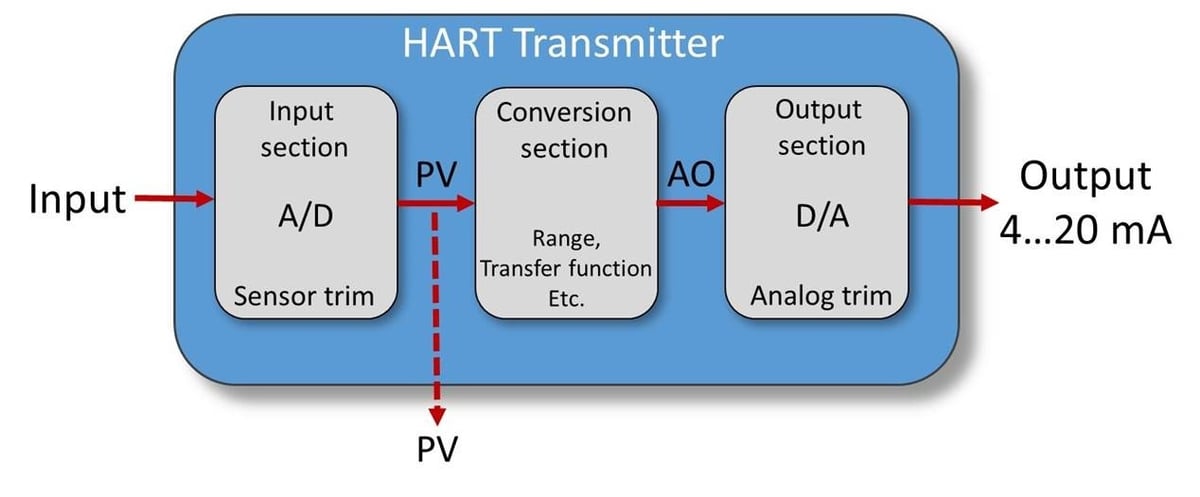

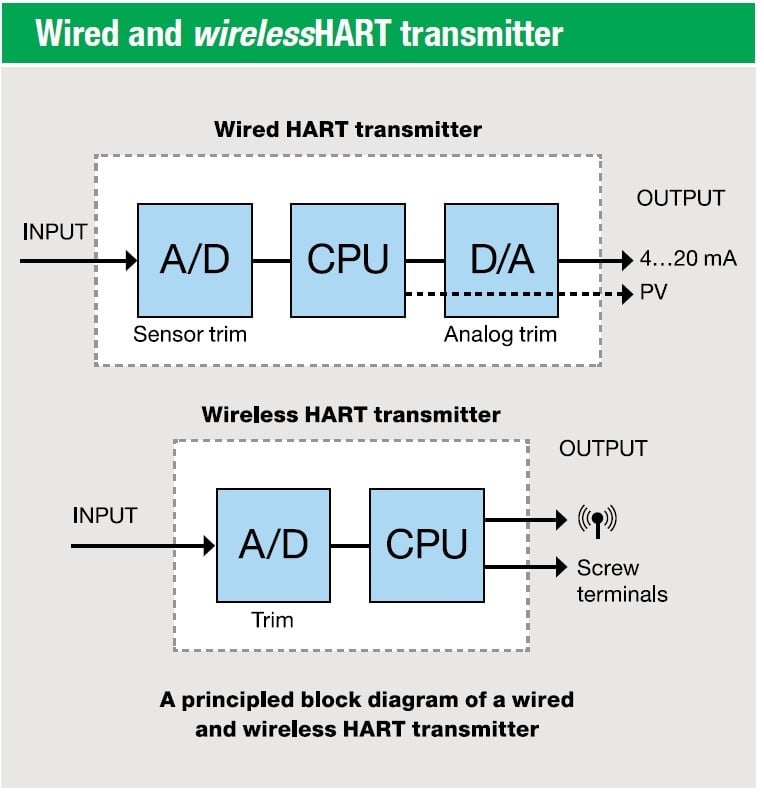

Using the digital output

In some cases in these high-accuracy flow applications, the differential pressure transmitter is not read through its analog 4–20 mA output but through its digital HART signal. One reason for this is to avoid unnecessary signal conversions. When using the analog output, the transmitter first converts its internal digital measurement into an analog current (D/A), and the control system then converts that current back into a digital value (A/D). Each conversion adds a small uncertainty.

By reading the transmitter’s measurement digitally over HART, these two conversion steps are removed. This reduces the overall uncertainty in the signal path and helps preserve the accuracy of the transmitter, especially in custody transfer applications or other situations where even very small errors in the flow signal can have financial impact.

The footprinting method applies in the same way regardless of whether the measurement is taken from the analog output or from the digital HART output. However, when the digital output is used, the calibration system must also compare the transmitter’s digital process variable (PV) to the correct footprint-adjusted target values. A modern calibration solution can handle this automatically, guiding the technician whether the reading comes from mA or from the digital HART PV.

Other considerations

Shortly, a few other considerations:

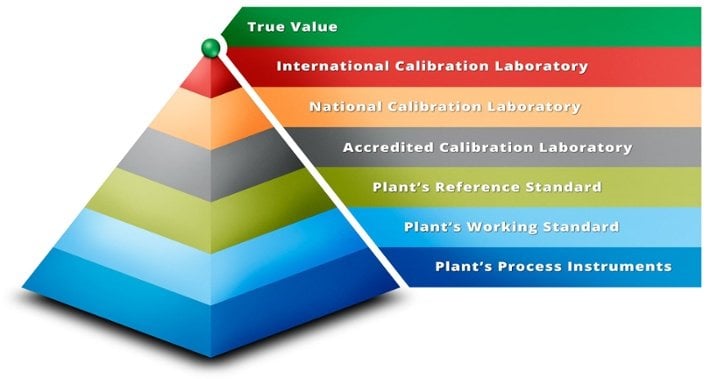

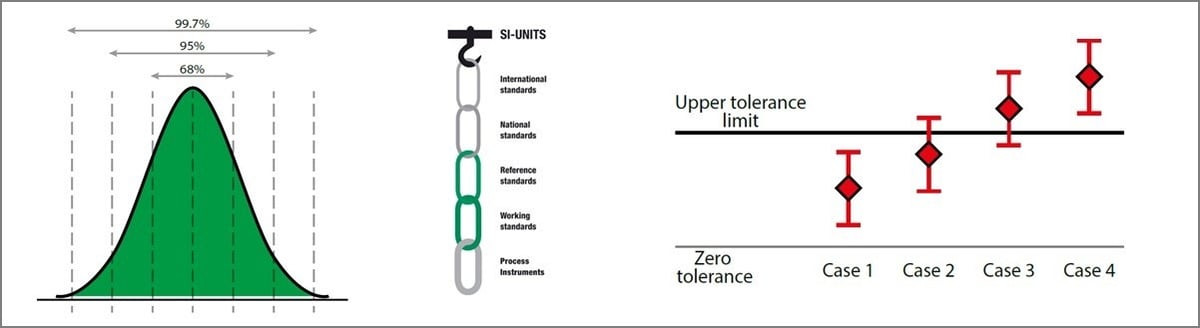

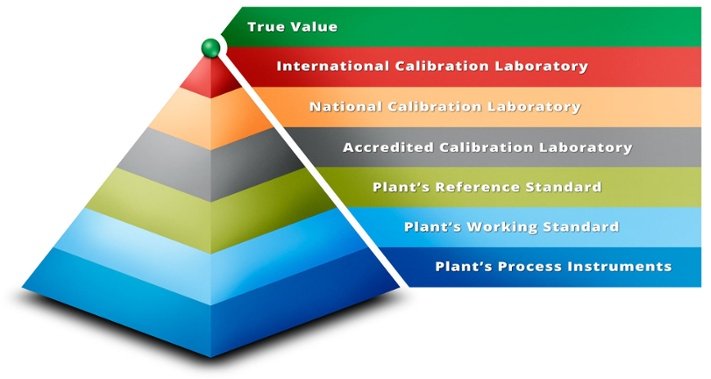

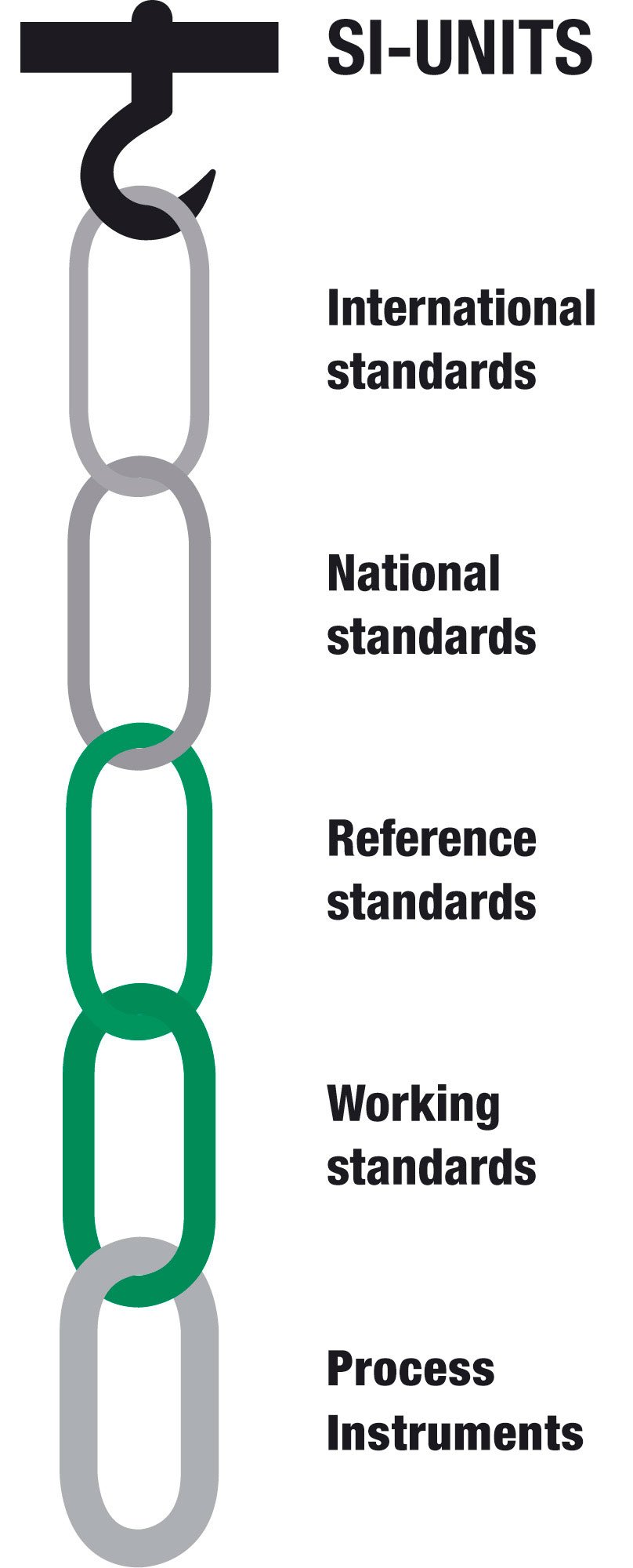

Traceability – As always in calibration, the formal metrological traceability of calibration is a must.

Accuracy – As accuracy is critical in these measurements, the high accuracy of calibration equipment is non-negotiable.

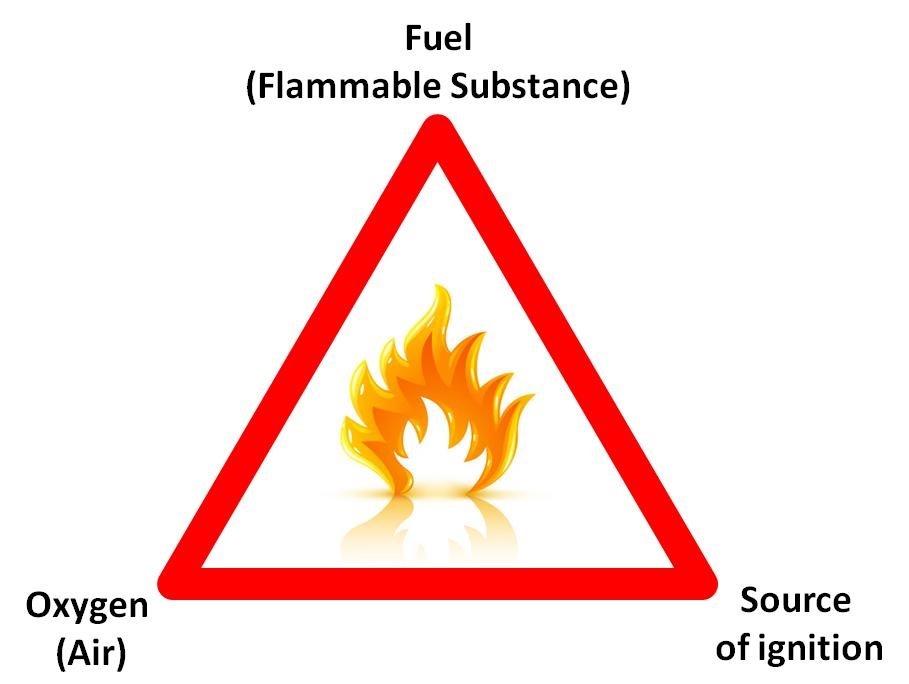

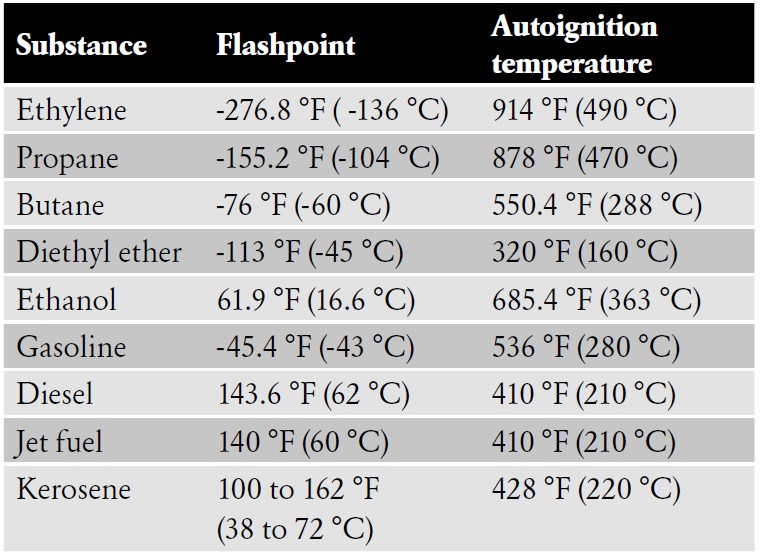

Safety – These measurements typically happen in hazardous areas, so the calibration equipment must be suitable for that environment.

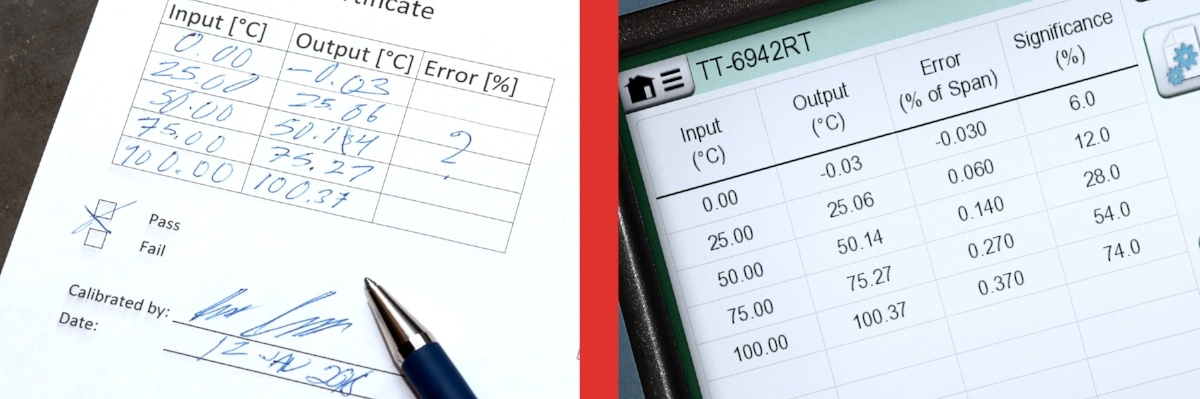

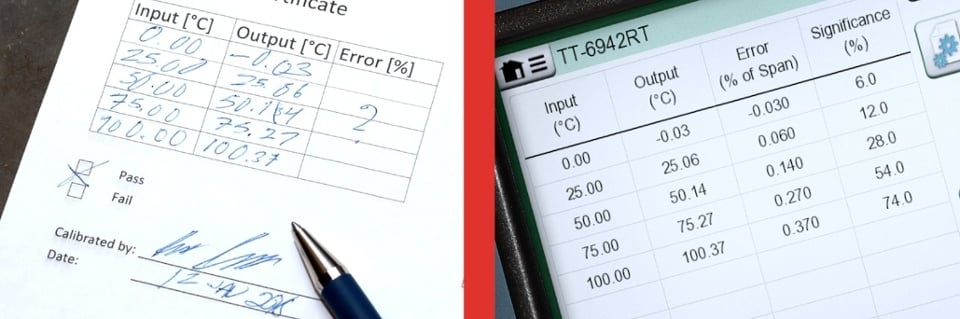

Documentation – Calibrations need to be documented, and instead of doing that the old fashioned way with pen and paper, documenting calibrators and calibration management software should be used.

Summary – Why footprinting matters

Footprinting is not just a laboratory exercise; it is a practical method that helps calibration professionals achieve accurate, reliable, and traceable results under real operating conditions.

By understanding how static (line) pressure affects a differential pressure transmitter, technicians and engineers can ensure that calibrations performed at atmospheric conditions still reflect how the transmitter behaves in the process. This is especially important in applications such as flow measurement in oil and gas, refining, or power generation, where even a small measurement error can have significant consequences.

Applying the footprinting method helps:

- Improve accuracy – The transmitter’s behavior under static pressure is known and compensated for.

- Enhance efficiency – Calibrations can be performed safely without applying high line pressure in the field.

- Increase consistency – Laboratory and field results correlate, even under different conditions.

- Ensure traceability – Footprint data, calibration results, and corrections are digitally documented.

When combined with modern digital calibration tools such as those that make up the Beamex ecosystem, footprinting becomes a straightforward and reliable part of the calibration process. The technician no longer needs to make manual corrections or guess offsets, and lab and field calibrations align perfectly.

I remember first discussing this topic with customers a couple of decades ago, and it’s interesting that the same challenge remains relevant today. The difference is that today we have the right tools to solve it. Footprinting may sound like a small detail, but for anyone working with differential pressure transmitters under high line pressure, it can make a big difference in measurement accuracy and confidence.

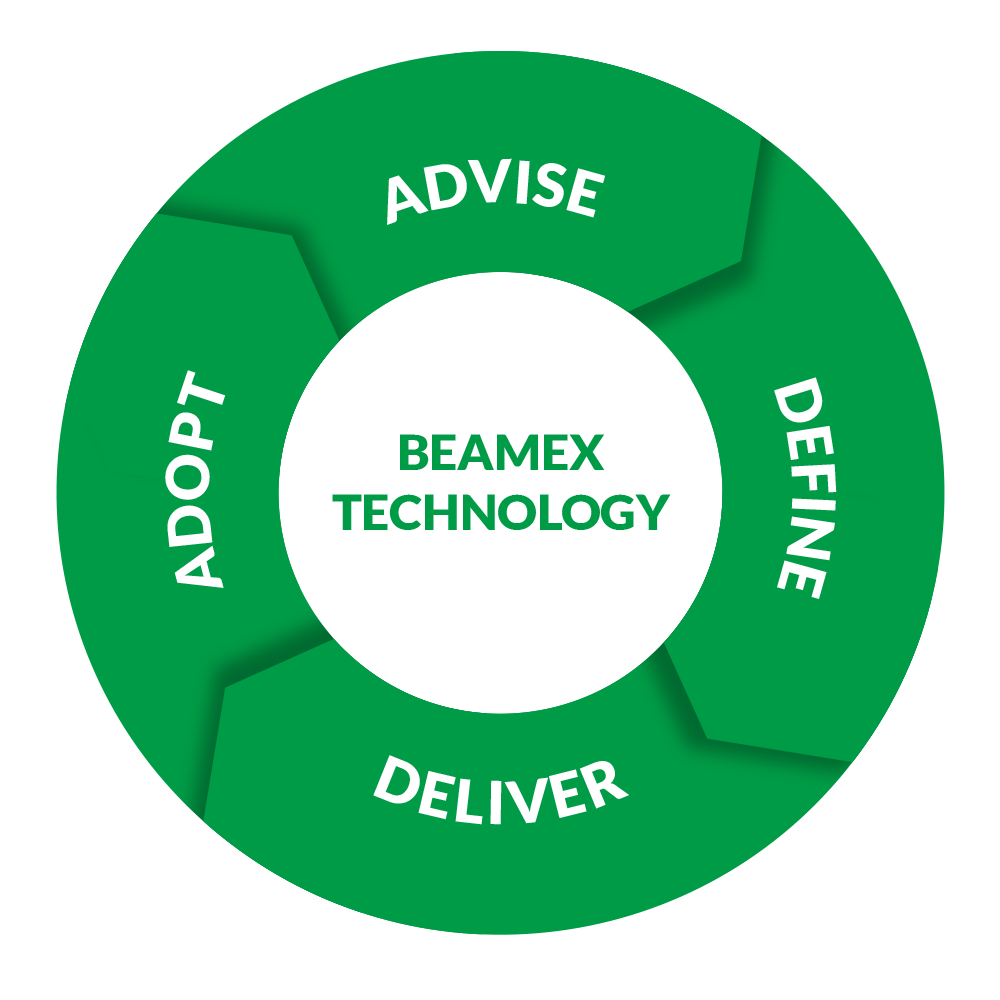

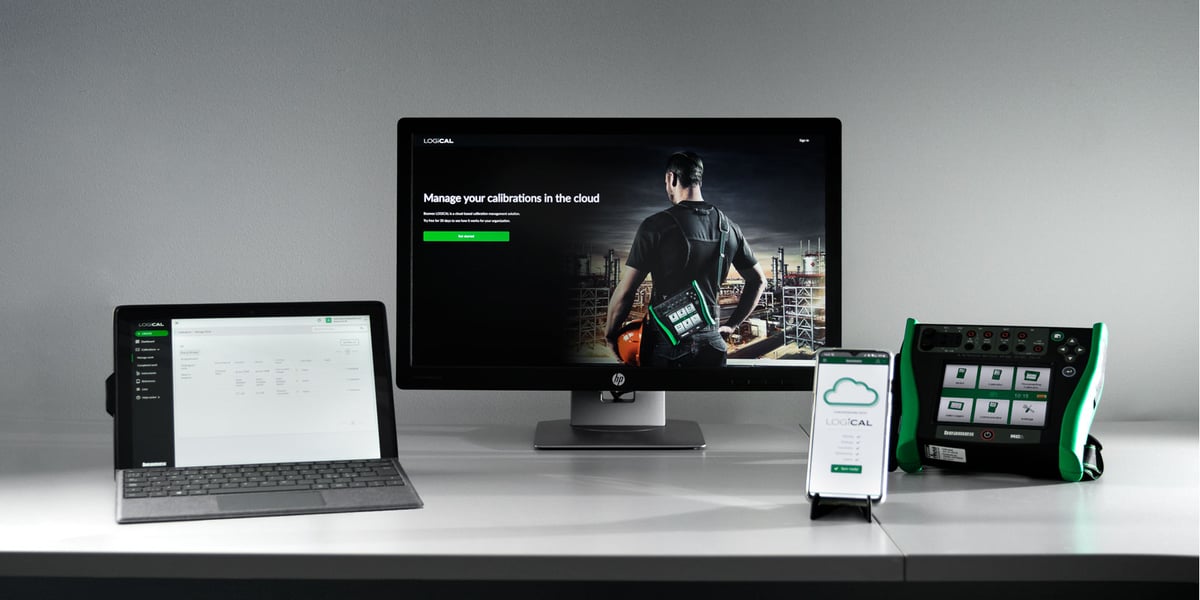

The Beamex solution – putting footprinting into practice

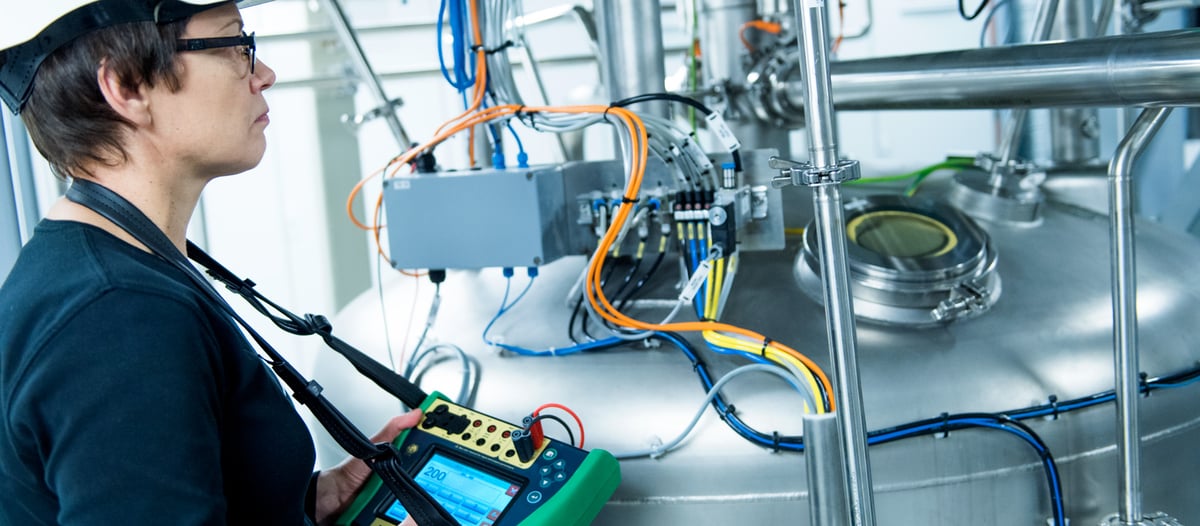

With the Beamex calibration ecosystem, the footprinting concept can be applied efficiently and in a fully traceable way. The Beamex ecosystem combines calibration tools with calibration management software, allowing you to capture, store, and use footprint information directly in your workflow.

The footprinting results from the accredited calibration laboratory can be used to program a "custom transfer function" for each pressure transmitter. This function guides the calibrator and the user on the required offsets and expected values during calibration.

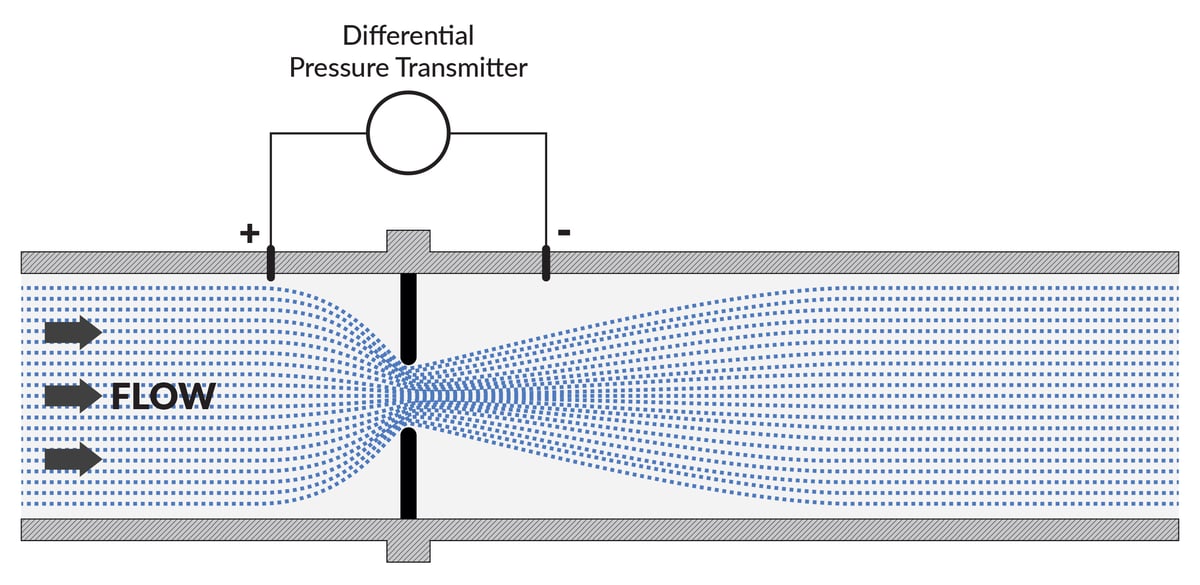

In practice, this means the technician no longer needs to manually check a paper offset table or perform calculations. The Beamex MC6 Advanced Field Calibrator and Communicator or MC6-Ex (for hazardous areas) displays what the transmitter should read at each calibration point, automatically taking the individual footprint correction into account. For instance, if the expected value at zero differential pressure is 4.020 mA, the calibrator guides the user accordingly and automatically evaluates the result.

The Beamex ecosystem also ensures the entire calibration process is fully digital and traceable. The footprint data, calibration results, and applied corrections are all digitally stored in the documenting calibrator, from where the results are transferred to the calibration management software. This ensures data integrity and helps maintain compliance with quality systems, standards, and audits.

This combination of high-accuracy calibrators, intelligent software, and expert services makes it easy to apply footprinting in both lab and field environments, whether you’re working in a calibration laboratory, a refinery, or even on an offshore platform.

If you want to streamline your pressure calibration process or learn how modern calibration tools and software can support your daily work, our specialists are ready to help.

Talk with a Beamex expert to find the best calibration approach for your plant.

Want to discuss your pressure calibration practices?

If you would like to improve your pressure calibration process, explore modern digital tools, or simply talk through the best way to handle challenging calibration scenarios, our experts are happy to help. Beamex has decades of experience supporting calibration professionals in a wide range of industries.

Contact our experts to find the right calibration approach for your needs.

Learn more about pressure calibration

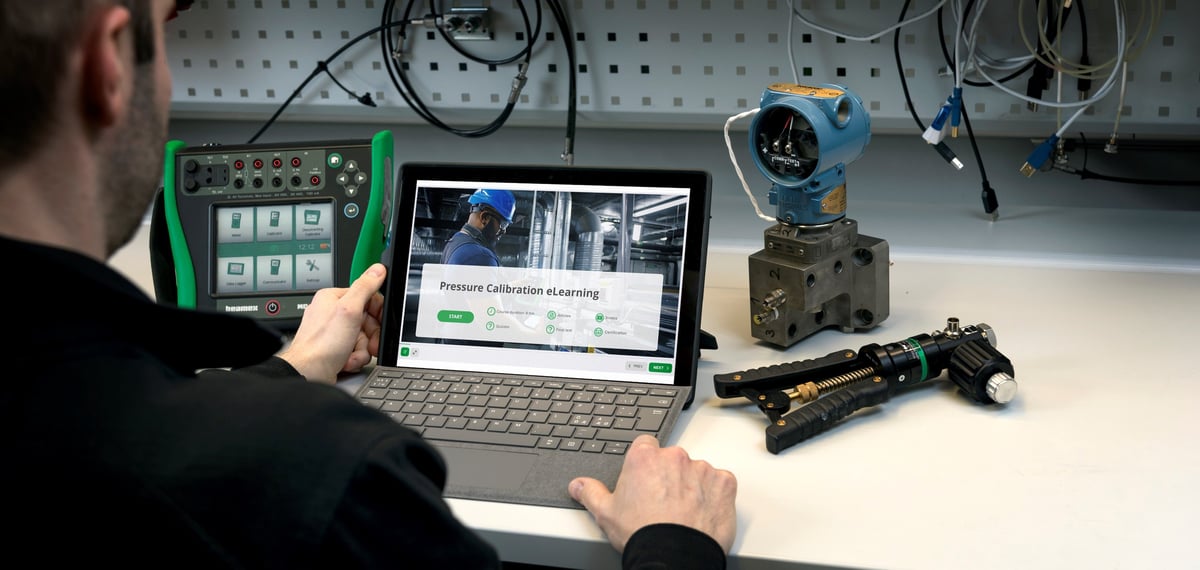

If you want to dive deeper into pressure calibration, we have collected a wide range of articles, guides, videos, and tools in our resource library.

Explore our pressure calibration content here >

For a more structured learning experience, we also offer the Beamex Pressure Calibration eLearning course, which covers pressure principles, calibration methods, uncertainty, and practical field considerations. It’s a great way to strengthen your understanding or train new technicians.

Learn more about our elearnings and enroll >

“It’s surprising to see how often plants are built without thinking of those who would have to come afterwards and prove/calibrate. I’ve seen for example a pressure test port aiming right at a wall with no clearance to connect.” Says

“It’s surprising to see how often plants are built without thinking of those who would have to come afterwards and prove/calibrate. I’ve seen for example a pressure test port aiming right at a wall with no clearance to connect.” Says

In the world of calibration management, choosing the right deployment model for your software makes all the difference. Whether your organization opts for a cloud-based or on-premises solution can significantly impact your operational efficiency, costs, and ability to adapt to future challenges.

In the world of calibration management, choosing the right deployment model for your software makes all the difference. Whether your organization opts for a cloud-based or on-premises solution can significantly impact your operational efficiency, costs, and ability to adapt to future challenges..png?width=1200&name=MC-family%20(1).png)

.png?width=1200&name=1998%20MC5%20(2).png)

At Beamex, we have a comprehensive range of solutions for

At Beamex, we have a comprehensive range of solutions for.png?width=1200&name=Blog%20size%20Customer%20service%20v2%20(1).png)

.png?width=1200&name=Blog%20size%20Customer%20service%20v2%20(2).png)

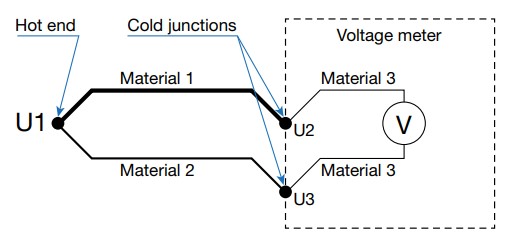

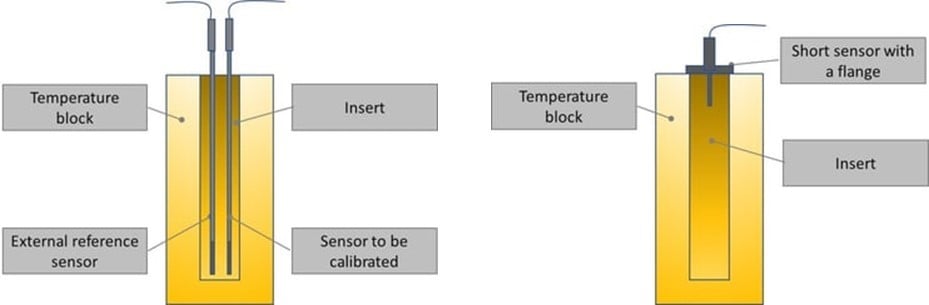

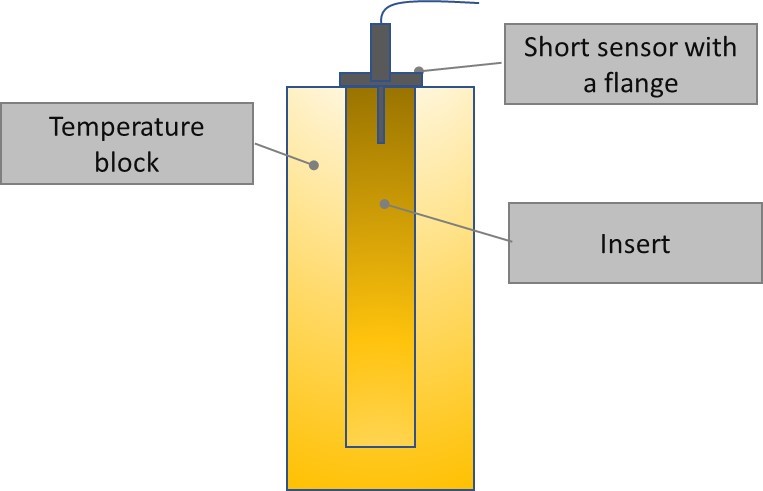

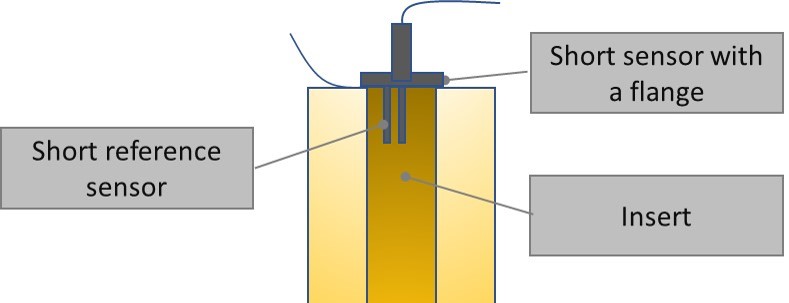

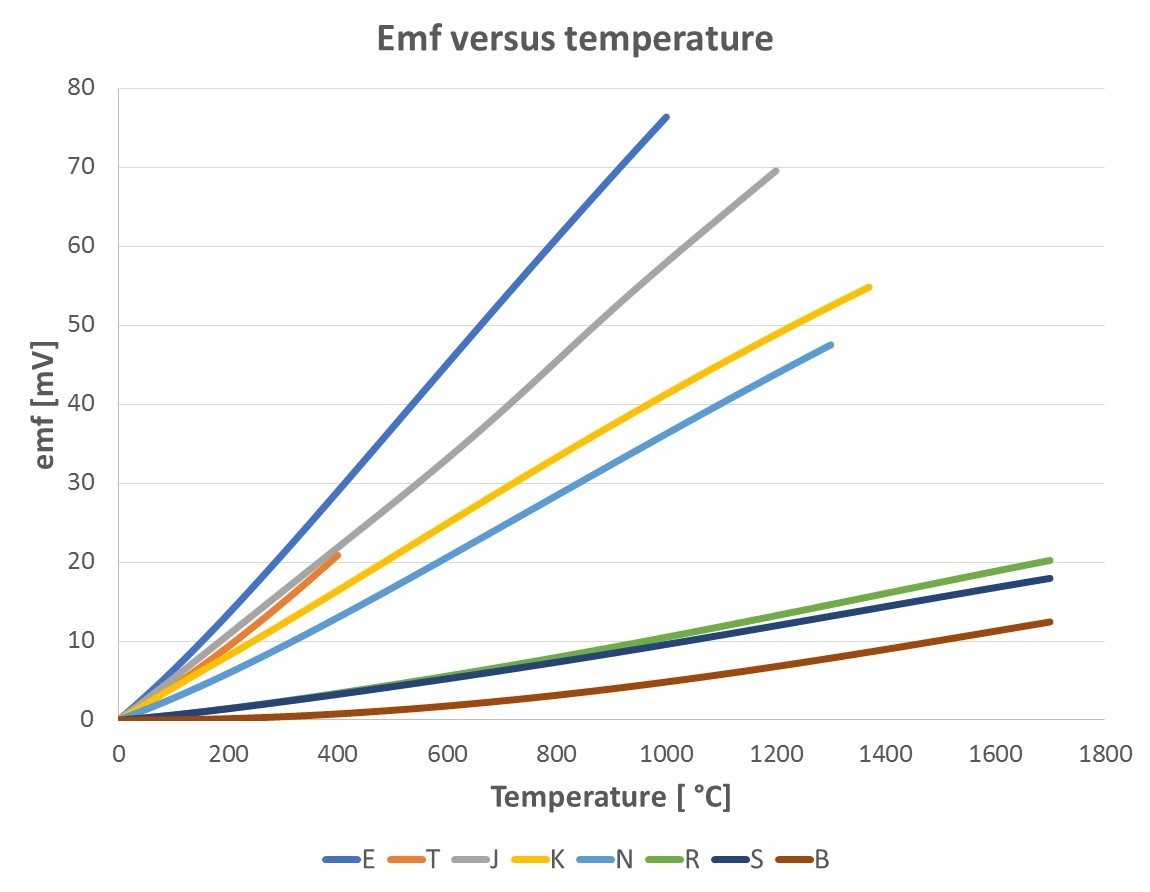

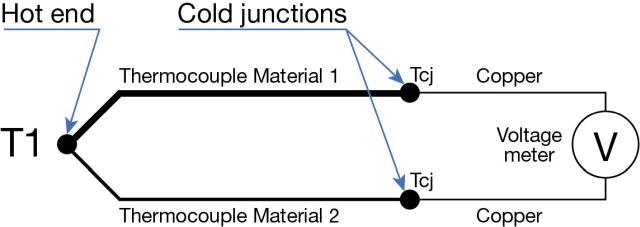

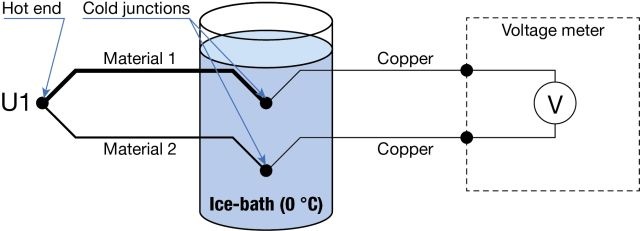

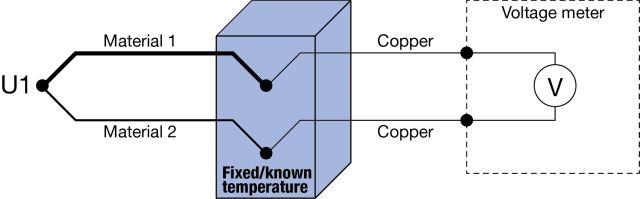

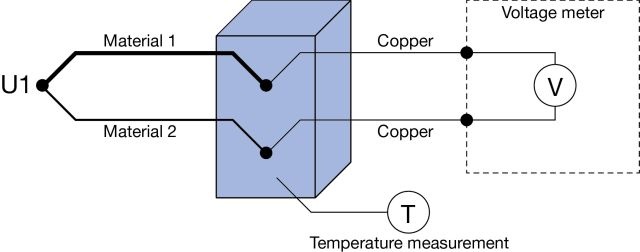

Simplified illustration of thermocouple cold junction.

Simplified illustration of thermocouple cold junction. Sanitary temperature sensor calibration

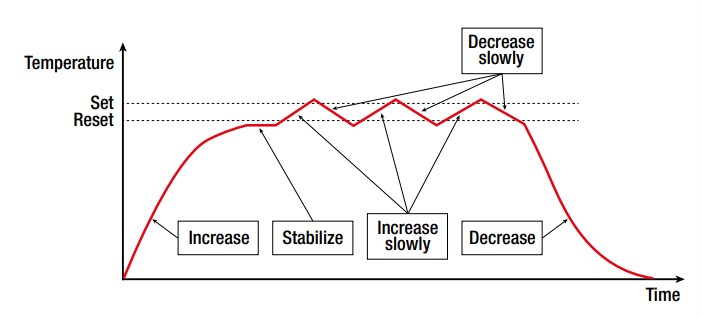

Sanitary temperature sensor calibration Temperature slope in temperature switch calibration.

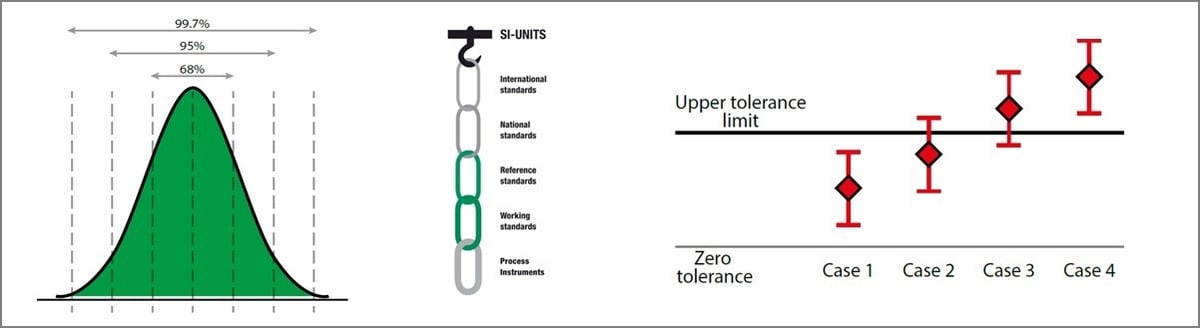

Temperature slope in temperature switch calibration. Calibration uncertainty

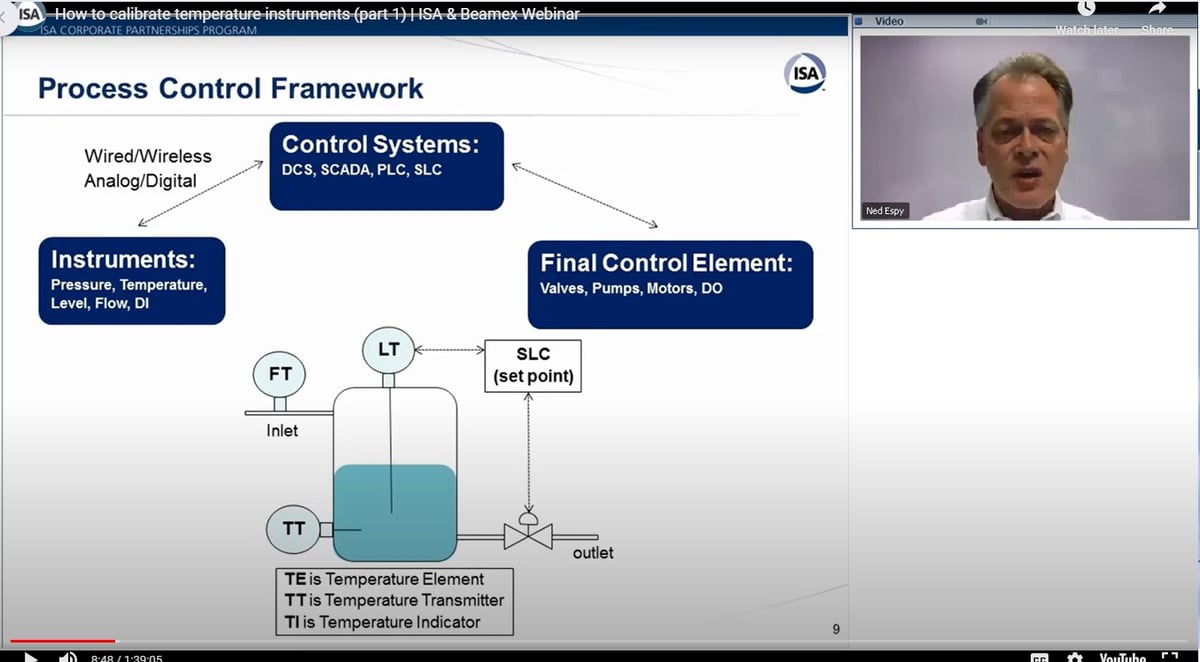

Calibration uncertainty Webinar: How to calibrate temperature instruments.

Webinar: How to calibrate temperature instruments.

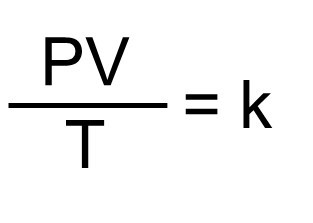

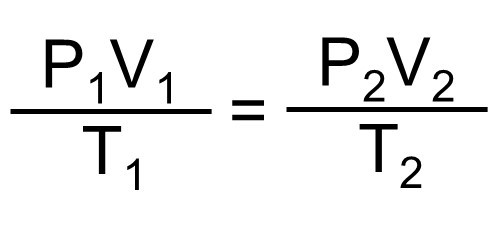

We can think of this formula as representing our normal pressure calibration system, having a closed, fixed volume. The two sides of the above formula represents two different stages in our system – one with a lower pressure and the second one with a higher pressure. For example, the left side (1) can be our system with no pressure, and the right side (2) the same system with high pressure applied.

We can think of this formula as representing our normal pressure calibration system, having a closed, fixed volume. The two sides of the above formula represents two different stages in our system – one with a lower pressure and the second one with a higher pressure. For example, the left side (1) can be our system with no pressure, and the right side (2) the same system with high pressure applied.

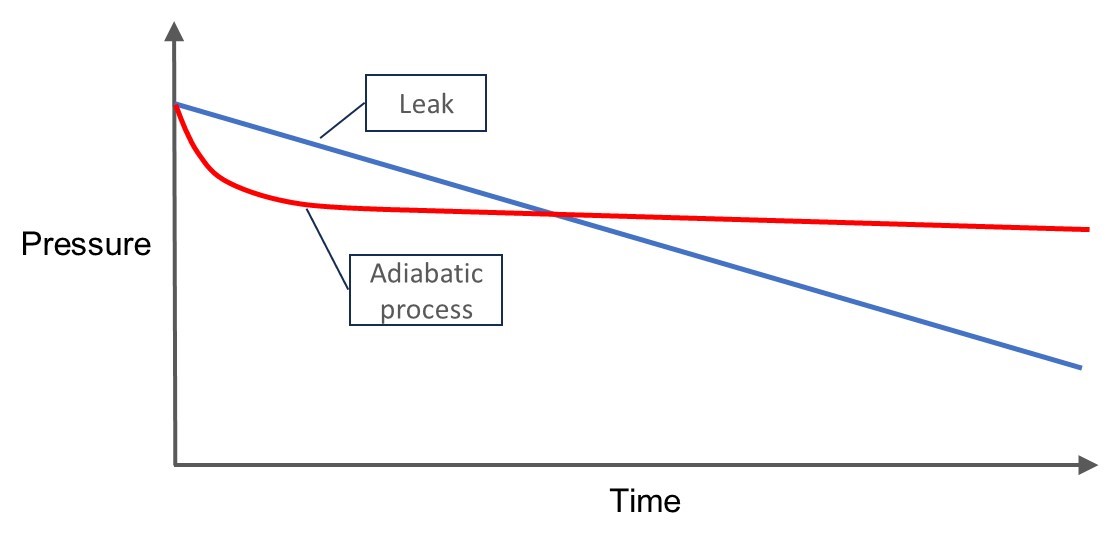

In the above image you can see how the pressure drop caused by the adiabatic process is first fast, but then slows down and eventually stabilizes (red line). While the pressure drop caused by a leak is linear (blue line).

In the above image you can see how the pressure drop caused by the adiabatic process is first fast, but then slows down and eventually stabilizes (red line). While the pressure drop caused by a leak is linear (blue line).

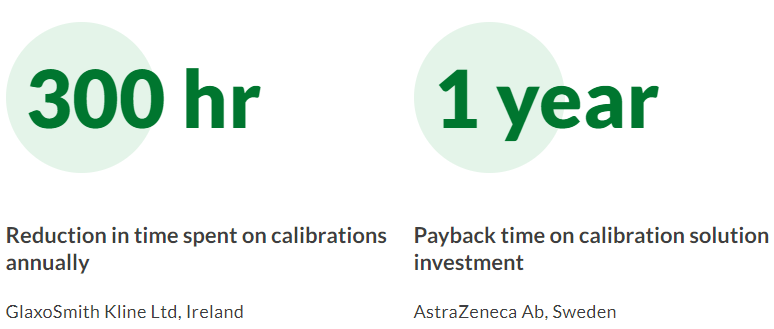

"With this software integration project, we were able to realize a significant return on investment during the first unit overhaul. It’s unusual, since ROI on software projects is usually nonexistent at first."

"With this software integration project, we were able to realize a significant return on investment during the first unit overhaul. It’s unusual, since ROI on software projects is usually nonexistent at first."

The Beamex solution has not been a hard sell at the compression station sites. “Beamex was very proactive in organizing online training for our teams, but the uptake was less than we expected because they are so easy to use that instead of asking basic questions during the training, our technicians were teaching themselves and quizzing the Beamex team on some fairly in-depth issues instead,” James Jepson says.

The Beamex solution has not been a hard sell at the compression station sites. “Beamex was very proactive in organizing online training for our teams, but the uptake was less than we expected because they are so easy to use that instead of asking basic questions during the training, our technicians were teaching themselves and quizzing the Beamex team on some fairly in-depth issues instead,” James Jepson says.

.png?width=1200&name=Calibration%20Software%20(1).png)

.png?width=1200&name=Black%20and%20Grey%20Bordered%20Travel%20Influencer%20YouTube%20Thumbnail%20Set%20(1).png)

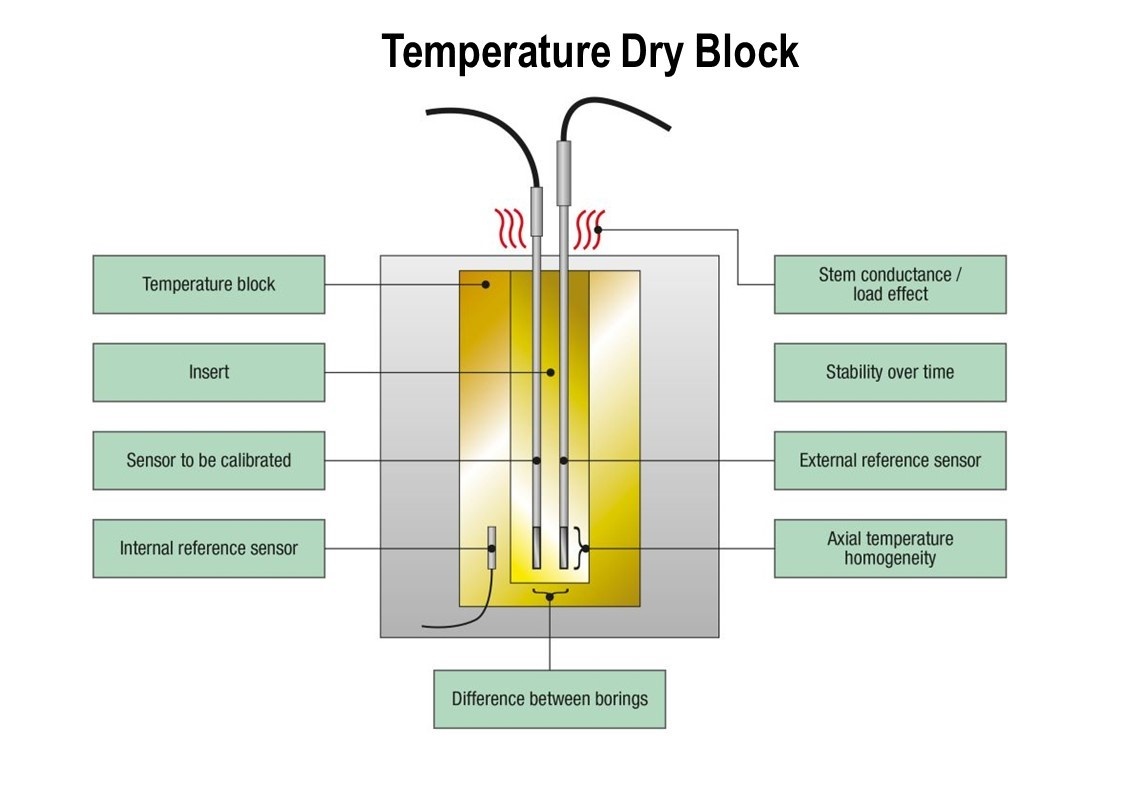

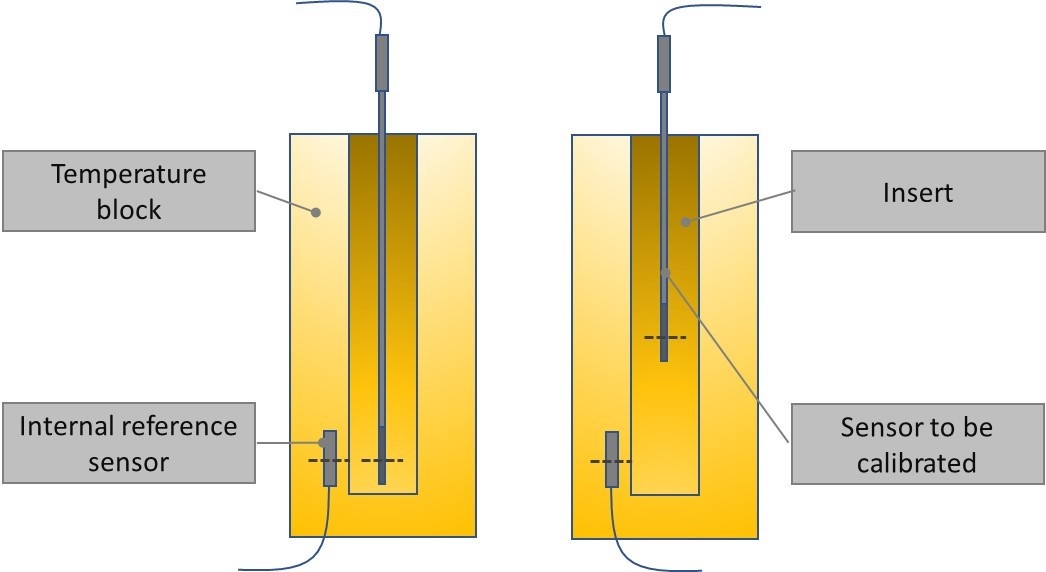

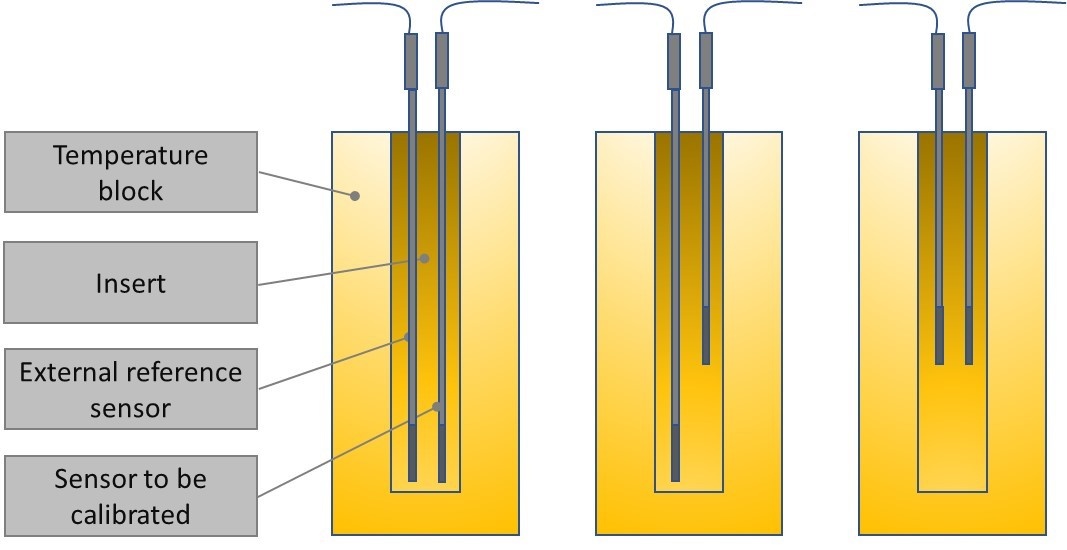

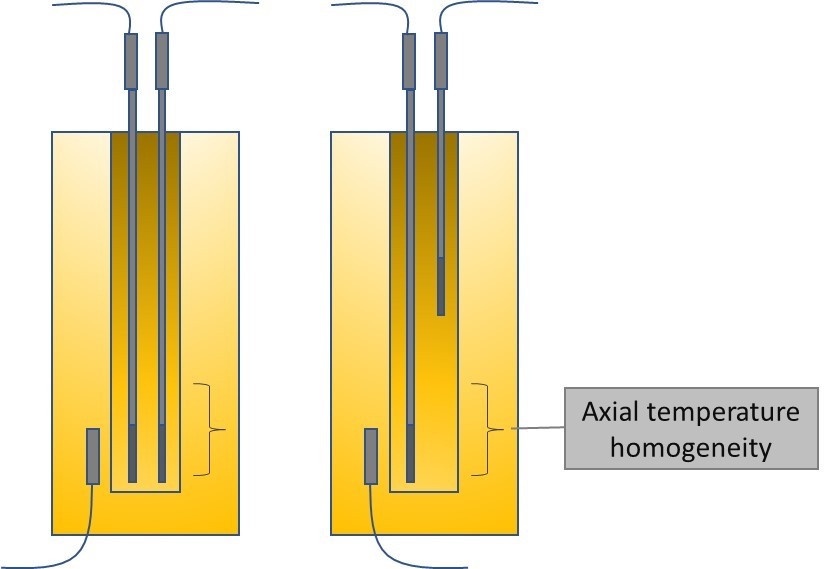

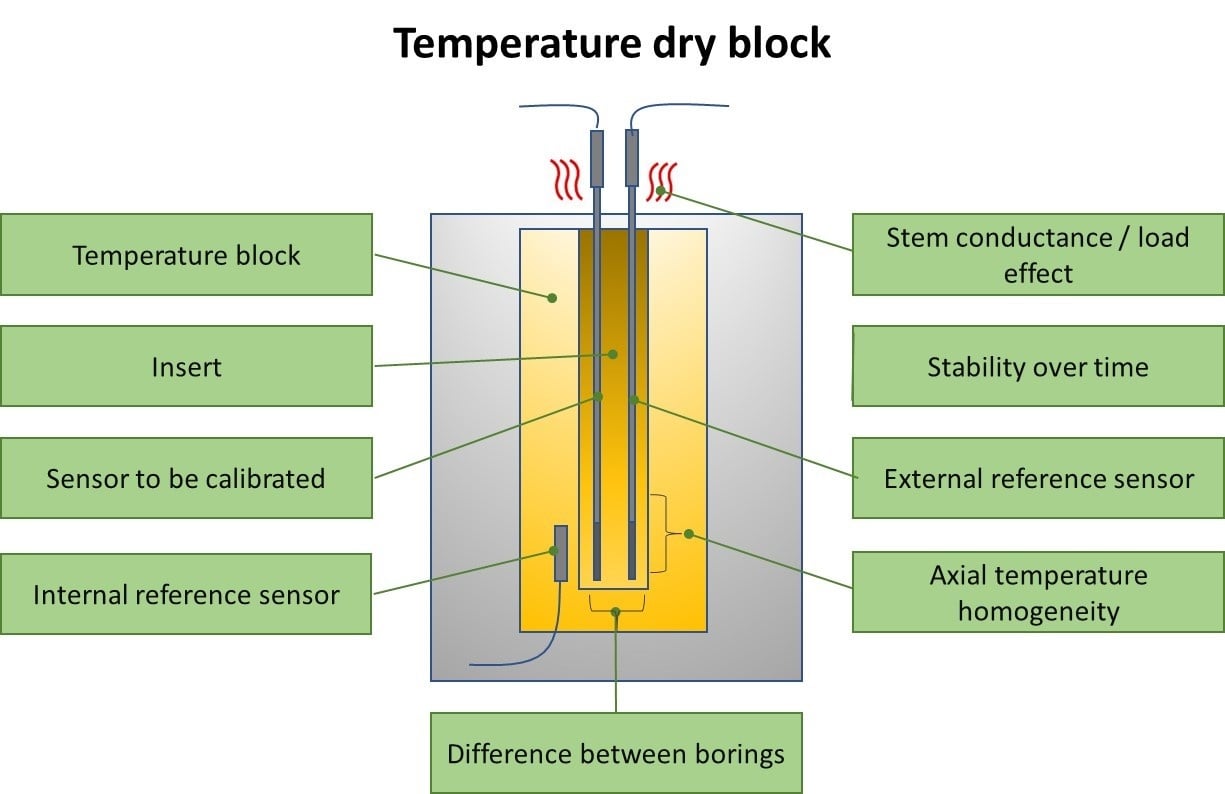

In this article, we will be covering the different uncertainty components that you should consider when you make a temperature calibration using a temperature dry block.

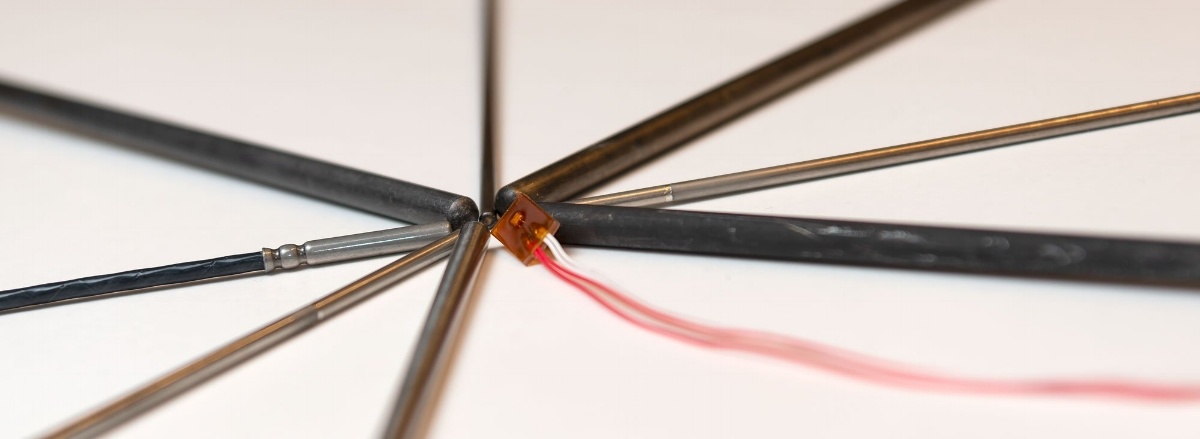

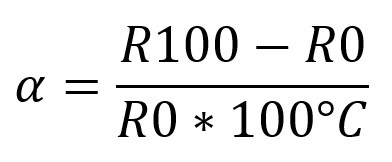

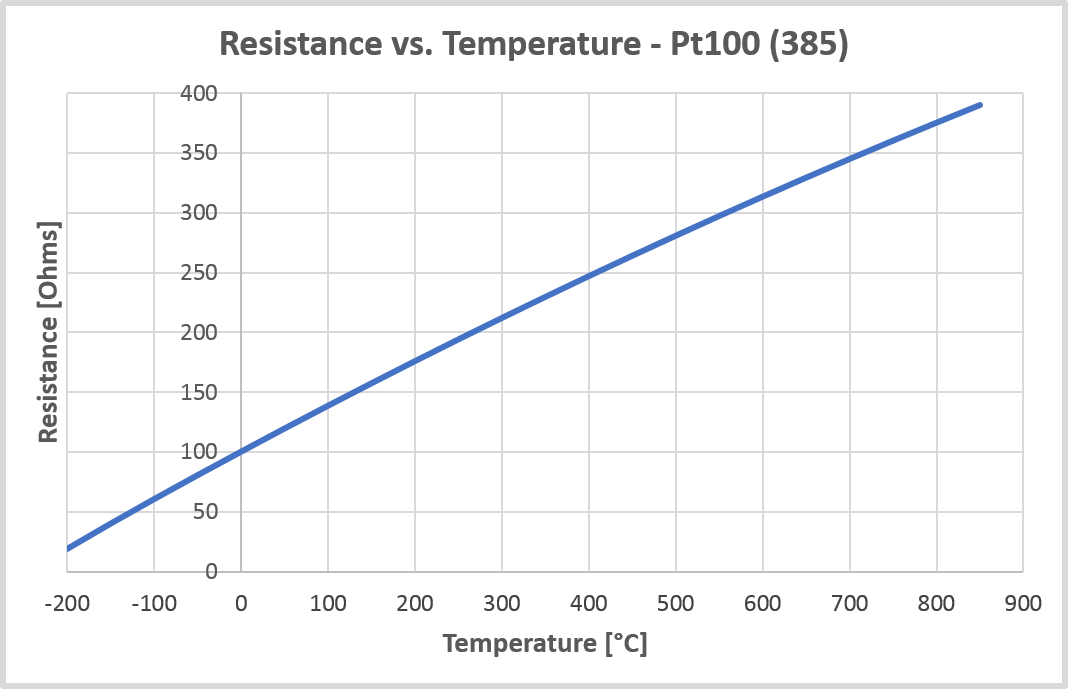

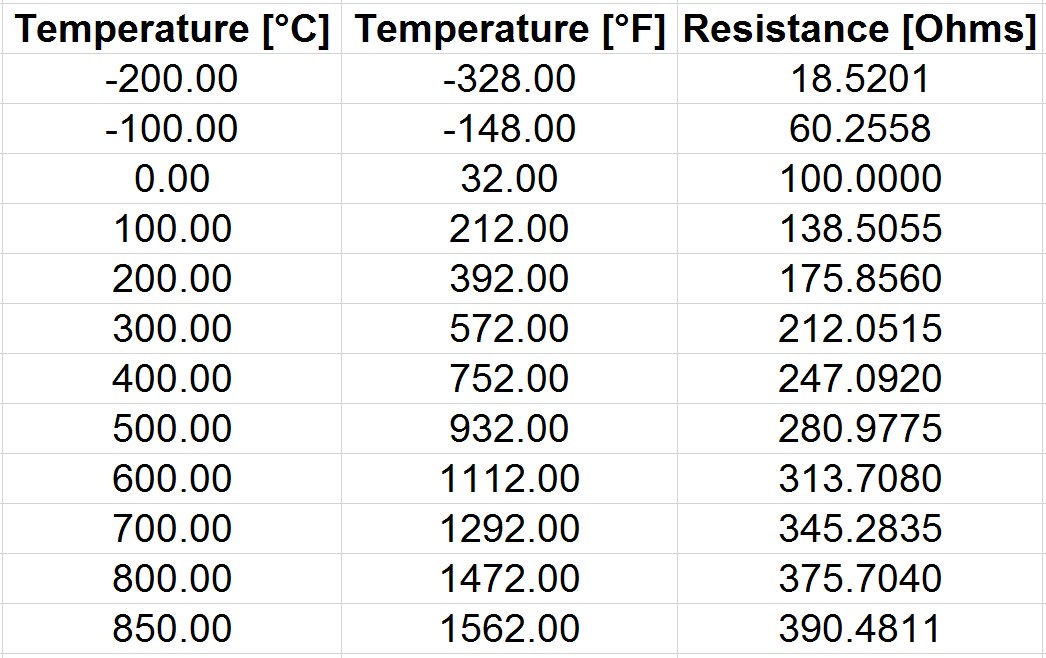

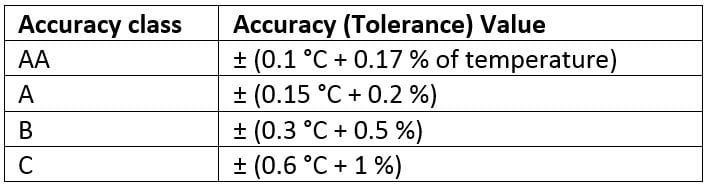

In this article, we will be covering the different uncertainty components that you should consider when you make a temperature calibration using a temperature dry block. Pt100 temperature sensors are very common sensors in the process industry. This article discusses many useful and practical things to know about the Pt100 sensors. There’s information on RTD and PRT sensors, different Pt100 mechanical structures, temperature-resistance relationship, temperature coefficients, accuracy classes and on many more.

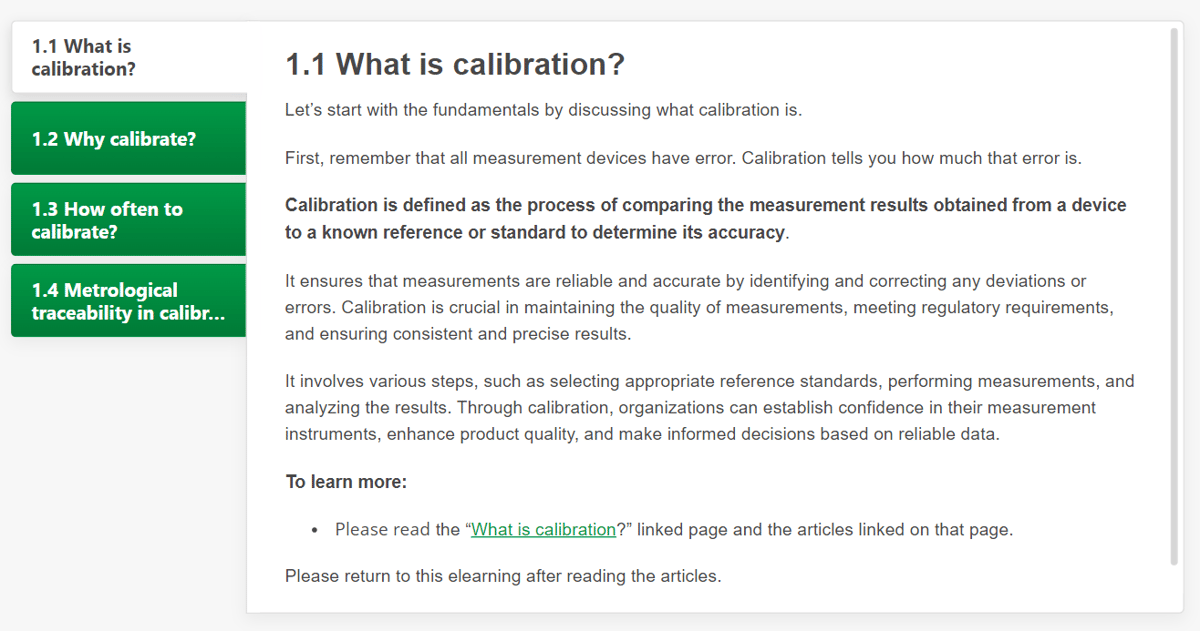

Pt100 temperature sensors are very common sensors in the process industry. This article discusses many useful and practical things to know about the Pt100 sensors. There’s information on RTD and PRT sensors, different Pt100 mechanical structures, temperature-resistance relationship, temperature coefficients, accuracy classes and on many more. Even people who work a lot with thermocouples don’t always realize how the thermocouples, and especially the cold (reference) junction, works and therefore they can make errors in measurement and calibration.

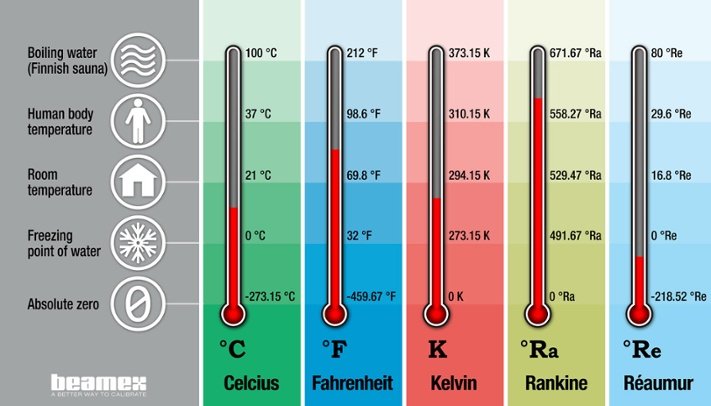

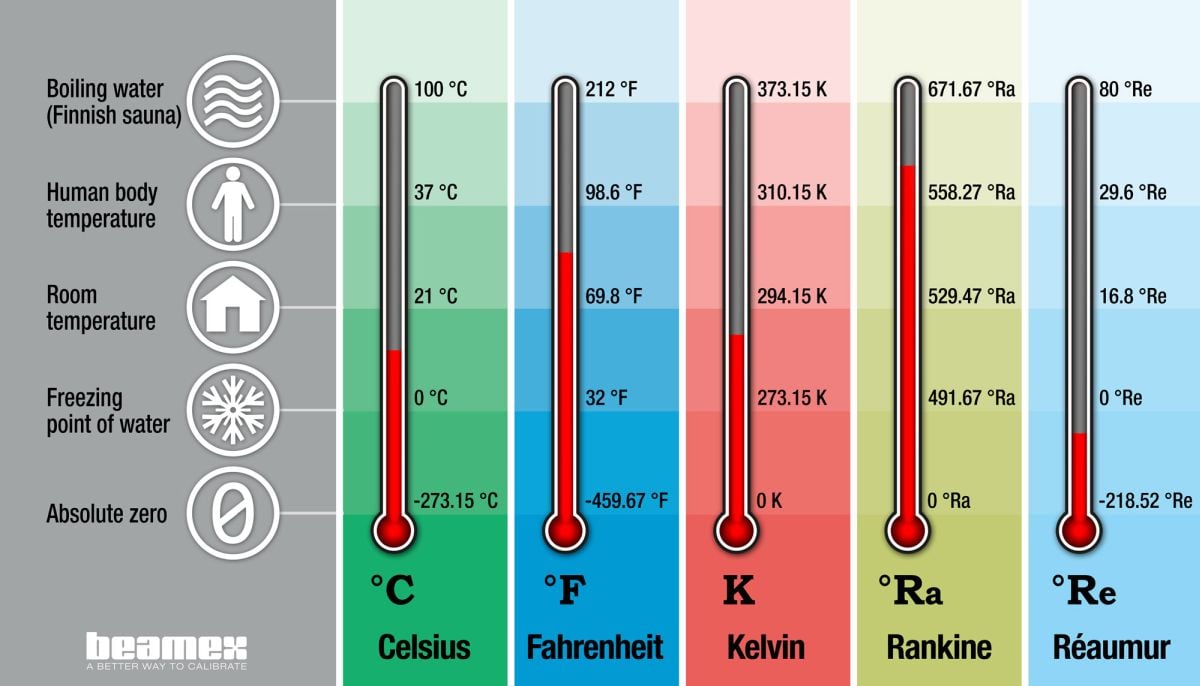

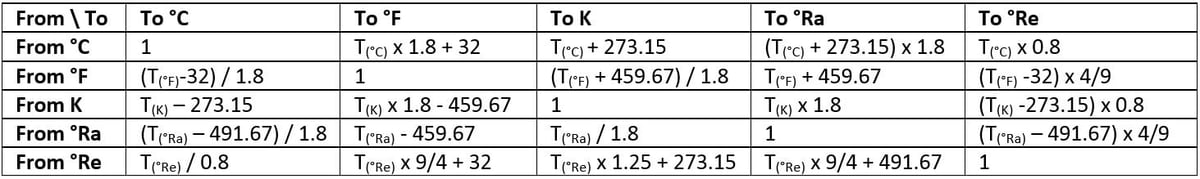

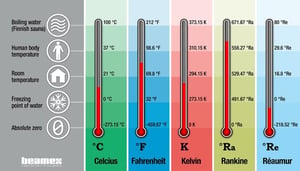

Even people who work a lot with thermocouples don’t always realize how the thermocouples, and especially the cold (reference) junction, works and therefore they can make errors in measurement and calibration. This article discusses temperature, temperature scales, temperature units and temperature unit conversions. Let’s first take a short look at what temperature really is, then look at some of the most common temperature units and finally the conversions between them.

This article discusses temperature, temperature scales, temperature units and temperature unit conversions. Let’s first take a short look at what temperature really is, then look at some of the most common temperature units and finally the conversions between them. Every temperature measurement loop has a temperature sensor as the first component in the loop. So, it all starts with a temperature sensor. The temperature sensor plays a vital role in the accuracy of the whole temperature measurement loop.

Every temperature measurement loop has a temperature sensor as the first component in the loop. So, it all starts with a temperature sensor. The temperature sensor plays a vital role in the accuracy of the whole temperature measurement loop. In this article, we will take a look at the AMS2750E standard, with a special focus on the requirements set for accuracy, calibration and test/calibration equipment.

In this article, we will take a look at the AMS2750E standard, with a special focus on the requirements set for accuracy, calibration and test/calibration equipment. Most calibration technicians follow long-established procedures at their facility that have not evolved with instrumentation technology. Years ago, maintaining a performance specification of ±1% of span was difficult, but today’s instrumentation can easily exceed that level on an annual basis. In some instances, technicians are using old test equipment that does not meet new technology specifications.

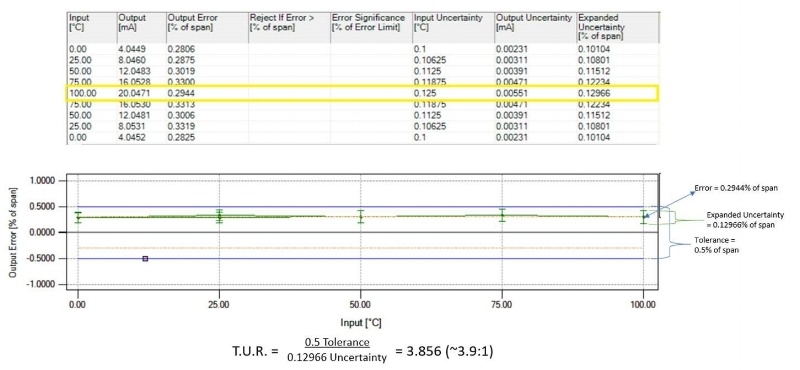

Most calibration technicians follow long-established procedures at their facility that have not evolved with instrumentation technology. Years ago, maintaining a performance specification of ±1% of span was difficult, but today’s instrumentation can easily exceed that level on an annual basis. In some instances, technicians are using old test equipment that does not meet new technology specifications.

Beamex’s suite of calibration management software can benefit all sizes of process plant. For relatively small plants, where calibration data is needed for only one location, only a few instruments require calibrating and where regulatory compliance is minimal,

Beamex’s suite of calibration management software can benefit all sizes of process plant. For relatively small plants, where calibration data is needed for only one location, only a few instruments require calibrating and where regulatory compliance is minimal,  Along with CMX, the

Along with CMX, the

![Beamex blog post - Picture of SRP site - How a business analyst connected calibration and asset management [Case Story]](https://resources.beamex.com/hs-fs/hubfs/Beamex_blog_pictures/SRP%20plant.jpg?width=1200&name=SRP%20plant.jpg)

mron, a Business Analyst at Salt River Project’s corporate headquarters in Tempe, Arizona, has been serving the company for more than 40 years and has helped develop Salt River Project’s calibration processes. Several years ago, he started to investigate the possibility of linking their calibration software,

mron, a Business Analyst at Salt River Project’s corporate headquarters in Tempe, Arizona, has been serving the company for more than 40 years and has helped develop Salt River Project’s calibration processes. Several years ago, he started to investigate the possibility of linking their calibration software,

.jpg?width=1200&name=Graph%201%20-tolerance%20(0.1).jpg)

.jpg?width=1200&name=Graph%202%20-%20tolerance%20(0.25).jpg)

.jpg?width=1200&name=Graph%203%20-%20tolerance%20(1).jpg)

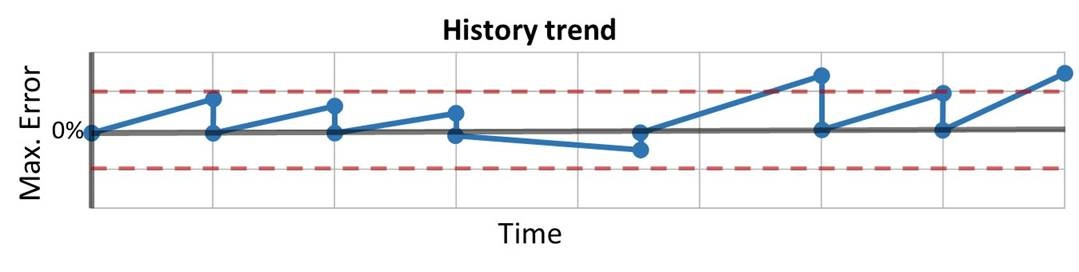

![How often should instruments be calibrated [update] - Beamex blog How often should instruments be calibrated [update] - Beamex blog](https://cdn2.hubspot.net/hub/2203666/hubfs/Beamex_blog_pictures/History_trend.jpg?width=1200&name=History_trend.jpg)

Figure 1. Linear versus square rooting.

Figure 1. Linear versus square rooting.

![Industrial Pressure Calibration Course [eLearning]](https://2203666.fs1.hubspotusercontent-na1.net/hub/2203666/hubfs/eLearning/Pressure%20elearning%20N%C3%A4ytt%C3%B6kuva%202024-11-29%20152932.png?width=300&name=Pressure%20elearning%20N%C3%A4ytt%C3%B6kuva%202024-11-29%20152932.png)

.jpg)

.png)

.png)

.png)

.png)

.png)