In the chemicals industry, safety is priority number one. But how do you ensure safety in a sustainable way? When it comes to calibration, the answer is a modern, digitalized, and automated solution.

There’s a reason safety is so important in the chemicals industry. If something goes wrong, it’s not just an issue for the plant and its employees – it can also impact people living in the surrounding area. This is one of the reasons that chemicals are so strictly regulated.

Chemical plants need to maintain strict quality management and hold detailed product information. Chemical process companies must be able to capture data from operational processes accurately in order to be prepared for product recalls. In case of audits, all of this data must be easy to find.

Learn more by downloading the full article here:

How automation helps

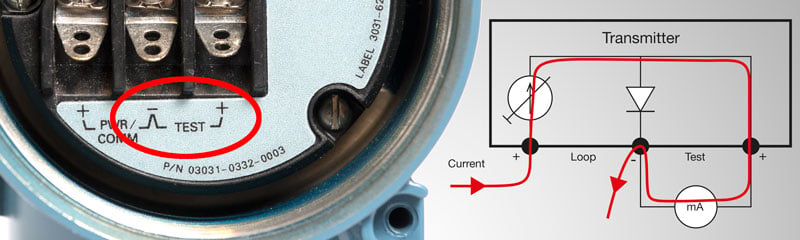

This is where automated and digitalized calibration solutions come into play. All of the instruments that are part of this safety process need to be accurately calibrated to ensure they’re working properly. However, in many plants this process still relies on paper certificates. While paper may feel reliable and tangible, there is a substantial risk of human error in the process. Each calibration typically has 20 data points or more, so even if the error rate for writing down results is only 1%, this means one in every five certificates is likely to contain faulty data.

With automated calibration, results are captured automatically in a digital format and sent securely to the calibration management system. This gives 100% accurate, tamper-proof results. Even better, finding certificates is as simple as performing an online search instead of manually looking through mountains of binders full of paper.

A repeatable process brings sustainability

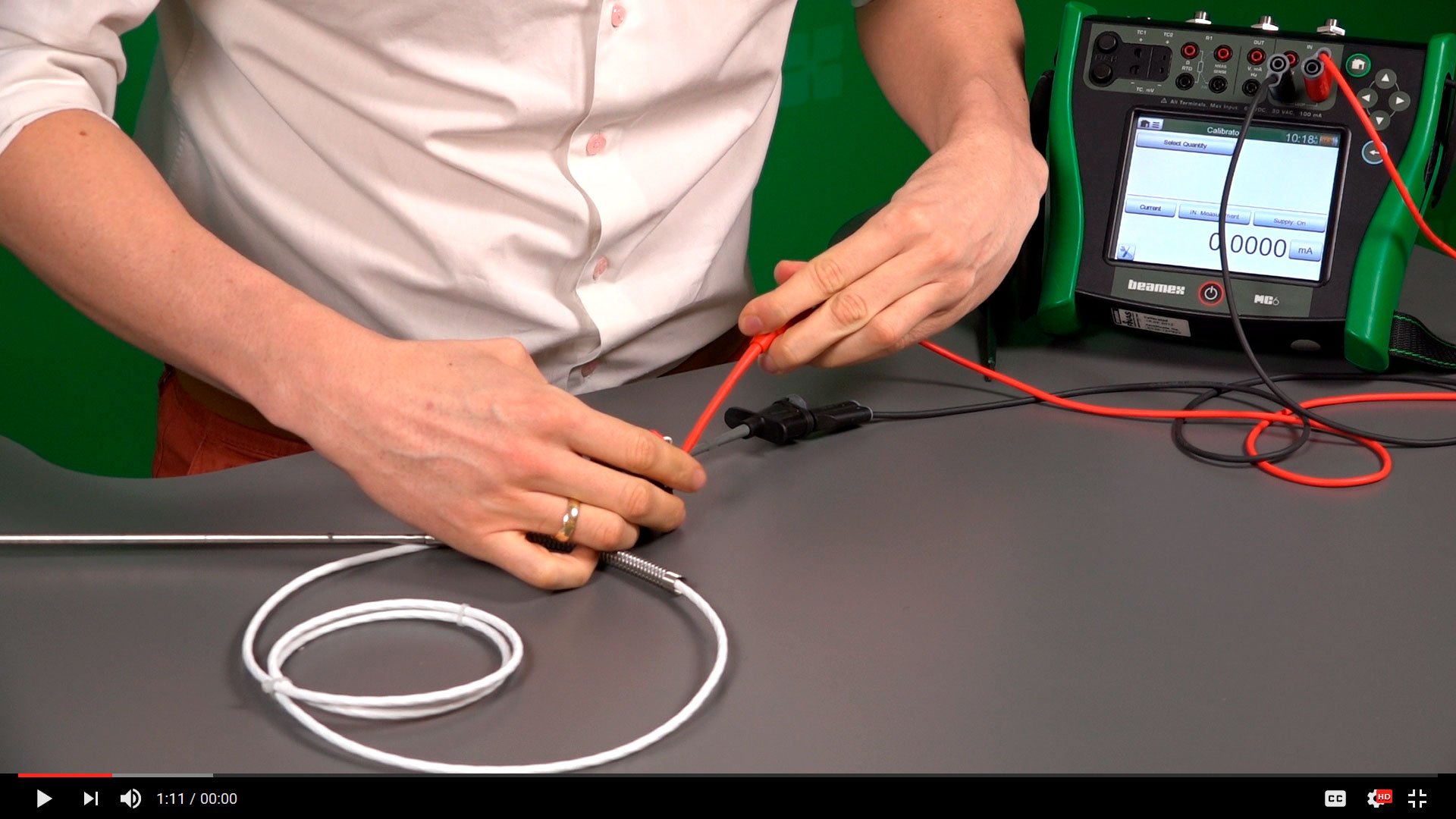

Another advantage of automated calibration is repeatability, which improves business sustainability. One challenge chemical plants face is the changing skill sets of the technicians who perform the calibrations. When this is combined with out-of-date test and measurement equipment, there is a genuine risk of instruments drifting out of tolerance.

Automated calibration helps solve this problem. Instead of varying in quality, every calibration is performed to the same highly accurate level as the calibrators can offer step-by-step guidance to technicians. The process is also faster – by cutting manual steps such as the need to fill in paper certificates or enter results into a database at the office, technicians can save 50% of the time needed for calibrations.

Ensuring safety

The repeatability, reliability, and accuracy of automated calibration also means better safety. This is because chemical plants can be sure that instruments critical for process safety are reliably calibrated and within tolerance. Well-designed calibration systems also enable technicians to include checklists as part of the calibration procedure – which is critical in ATEX environments and other scenarios where very clear procedures need to be followed to ensure safety.

Beamex calibration ecosystem

Beamex offers an automated calibration ecosystem that is composed of a unique mix of expertise and technology to help chemical companies sustainably improve process safety. Beamex solutions provide accurate measurements, reliable data, and traceability, which helps to reduce uncertainty and errors in calibration data. The end result is consistent calibration quality at your chemical plants.

Learn more about Beamex products and services on our website or contact your local Beamex representative:

Related chemical articles

- Safe and sound operations for fine chemicals

- Ensuring safety and sustainability in the fine chemicals industry

- How automated calibration changes the game in the fine chemicals industry

Related blog posts

- How to avoid safety and compliance issues in fine chemicals

- Automating the calibration management ecosystem

- Improving efficiency and ensuring compliance in the pharmaceutical industry

- CMMS and calibration management integration - Bridging the gap

- How a business analyst connected calibration and asset management [Case Story]

- Do more with less and generate ROI with an Integrated Calibration Solution

- Common Data Integrity Pitfalls in Calibration Processes

- Calibration management - transition from paper-based to digital

Download your copy of the Calibration Essentials Software eBook to learn more about calibration management and software.

![How often should instruments be calibrated [update] - Beamex blog](https://blog.beamex.com/hubfs/Beamex_blog_pictures/History_trend.jpg)

.jpg)

Discussion