In industries like oil and gas, chemicals, pharmaceuticals, and power generation, safety is not just a regulatory checkbox — it’s a core element of sustainable, reliable operations. Every day, companies work to reduce risk, protect their workforce, safeguard the environment, and maintain public trust.

At the heart of many of these efforts is functional safety, and a central tool in functional safety is the Safety Instrumented System (SIS). An SIS monitors critical process conditions and, when needed, automatically takes protective actions to bring the process to a safe state. To define the reliability required from each safety function, organizations use the Safety Integrity Level (SIL) framework.

However, even the most advanced safety system will fail if not properly maintained. Without regular calibration and proof testing, an SIS can degrade, leaving operations vulnerable to hazards. This blog post explains SIS, SIL, functional safety, calibration practices, global standards, and how companies can strengthen their safety programs.

For those wanting a deeper dive, we also invite you to download more detailed white paper on this topic. Also, we include a link to a webinar recording we did with ISA.

Download a more detailed white paper on this topic >

Watch webinar recording: For those interested in deepening their understanding, we recommend watching the recorded webinar co-hosted by Beamex and the International Society of Automation (ISA), featuring functional safety expert Paul Gruhn. This session provides valuable educational insights into SIS fundamentals, standards, and real-world challenges. Watch the webinar recording >

Table of contents

- Introduction

- What is a Safety Instrumented System (SIS)?

- Functional Safety and SIS

- What is SIL and how does it relate to SIS?

- Industries where SIS and SIL are used

- Overview of related standards

- Calibration and proof testing of SIS components

- Calibration frequency requirements

- Regulatory oversight and auditing

- Best practices and Beamex solutions

- Conclusion

Introduction

In high-risk industries like oil and gas, chemicals, and power generation, safety isn’t just about ticking regulatory boxes — it’s essential for keeping operations running reliably and protecting people and the environment.

One of the most important frameworks behind industrial safety is functional safety, and at its core lies the Safety Instrumented System (SIS). SIS is designed to detect dangerous conditions and automatically take action. To ensure these systems work as intended, each safety function is assigned a Safety Integrity Level (SIL).

But even the best technology won’t deliver results without proper maintenance and calibration. In this blog, we’ll explore what SIS and SIL really mean — and why calibration plays a critical role in keeping these systems safe, compliant, and audit-ready.

What is a Safety Instrumented System (SIS)?

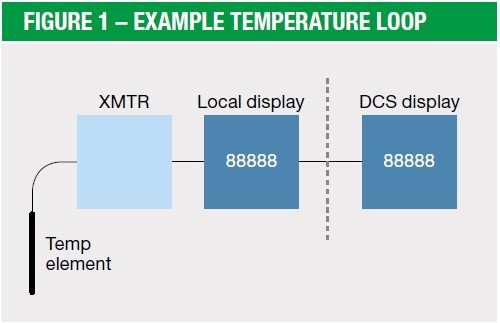

A Safety Instrumented System (SIS) is an independent system designed to monitor and automatically control hazardous process conditions. It is made up of:

- Sensors that measure critical process variables like pressure, temperature, flow, or gas concentrations,

- Logic solvers (typically safety-rated PLCs) that evaluate sensor signals and decide if protective action is required,

- Final control elements such as shutdown valves or actuators that carry out the safety response.

Unlike the Basic Process Control System (BPCS), which manages routine operations, the SIS is designed to handle extreme conditions.

For example, if pressure in a chemical reactor rises beyond safe limits, the SIS may automatically close isolation valves and shut down feeds to prevent a rupture or explosion.

The independence and reliability of the SIS are crucial because it is often the last line of defense when other systems fail.

The image below is a screenshot from a recent webinar we hosted in collaboration with the International Society of Automation (ISA), featuring functional safety expert Paul Gruhn. It illustrates how the SIS is an independent system, separate from the basic process control system (BPCS). Watch the webinar recording >.

At a recent user group meeting in Australia, Jason Lang, an Electrical Engineer from Stanwell Corporation, presented how they use the Beamex solution for their SIS calibrations. In his presentation, he included the image below to explain the structure of the SIS:

Functional Safety and SIS

Functional safety ensures that automatic systems detect and respond to unsafe conditions, reducing risks to acceptable levels. It’s about making sure protective systems — like the SIS — work correctly and reliably when called upon.

A key framework in functional safety is the safety lifecycle, which includes:

- Identifying hazards and assessing risks,

- Defining safety requirements,

- Designing and engineering the system,

- Installing and commissioning,

- Operating, maintaining, and modifying the system over time.

Importantly, functional safety does not stop at commissioning. Without regular calibration, proof testing, and maintenance, even the best-designed systems can degrade, leaving the facility vulnerable to hidden risks.

What is SIL and how does it relate to SIS?

The Safety Integrity Level (SIL) is a performance measure assigned to a Safety Instrumented Function (SIF) — a specific protective loop within the SIS. SIL helps define how reliably that function must work to achieve the desired risk reduction.

There are four SIL levels:

- SIL 1 → modest risk reduction,

- SIL 2 → significant risk reduction,

- SIL 3 → high risk reduction,

- SIL 4 → extremely high risk reduction (rare outside of nuclear or aerospace applications).

SIL determination is part of risk assessments like HAZOP (Hazard and Operability Study) or LOPA (Layer of Protection Analysis). The assigned SIL guides design decisions, equipment selection, system architecture, redundancy, and testing intervals.

For example, a SIL 2 loop protecting a pipeline overpressure event may need annual proof tests, while a SIL 3 emergency shutdown loop on a high-pressure reactor may require semi-annual testing and redundant sensors.

Industries where SIS and SIL are used

SIS and SIL systems are critical across industries where equipment failures can have catastrophic consequences:

- Oil and Gas: Used on offshore platforms, pipelines, refineries, and LNG terminals to prevent fires, explosions, and toxic releases.

- Chemical and Petrochemical: Protects reactors, distillation units, and storage tanks from overpressure, runaway reactions, and leaks.

- Pharmaceutical and Biotech: Ensures safety in solvent storage, sterilization processes, and bioreactors.

- Power Generation: Safeguards turbines, boilers, and hydrogen systems from overspeed, overpressure, and fires.

- Mining and Metals: Used in ore processing, smelting, and gas handling systems.

- Food, Beverage, and Pulp and Paper: Common in ammonia refrigeration systems and chemical recovery boilers.

In each sector, the SIS is a crucial safeguard protecting lives, assets, and business continuity.

Overview of related standards

Several international and national standards govern SIS and SIL:

- IEC 61508: General functional safety standard across industries.

- IEC 61511 / ANSI/ISA 61511: Process industry-specific standard.

- API RP 556, API 670, API RP 754: Oil and gas industry standards.

- NFPA 85, NFPA 86: Fire protection and combustion systems.

- OSHA PSM (USA): Process safety management rule.

- Seveso III Directive (EU), COMAH (UK): Major hazard site regulations.

- China GB, Russia GOST: National standards aligning with IEC frameworks.

Compliance with these standards is not optional — it’s required by regulators and critical for legal, operational, and reputational protection.

Calibration and proof testing of SIS components

Calibration and proof testing ensure that SIS components function reliably when needed.

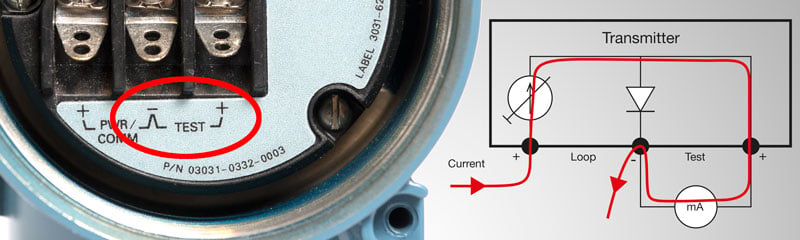

- Sensors and transmitters (pressure, temperature, flow, gas detectors) are the eyes of the system. Over time, environmental conditions, vibration, or chemical exposure can cause drift. Regular calibration keeps them accurate and prevents dangerous underperformance or nuisance trips.

- Final control elements (valves, actuators, relays) are the muscle of the system. They must be tested — often through partial stroke and full stroke tests — to confirm they will actuate on demand.

- Logic solvers (safety PLCs) require functional verification to ensure they correctly process inputs and trigger outputs.

Calibration in SIS environments can be challenging due to harsh conditions, confined spaces, and hazardous areas. Intrinsically safe, multifunction calibrators and well-trained technicians are essential.

Challenges in the field

Maintaining a robust SIS calibration program can be challenging. Field conditions are often harsh, with exposure to extreme temperatures, vibration, and corrosive environments. Access to devices may require confined space entry or working at height. Technicians must be well-trained, using intrinsically safe, accurate equipment, and following standardized procedures.

“It’s surprising to see how often plants are built without thinking of those who would have to come afterwards and prove/calibrate. I’ve seen for example a pressure test port aiming right at a wall with no clearance to connect.” Says Roy Tomalino, one of our training experts in the USA.

“It’s surprising to see how often plants are built without thinking of those who would have to come afterwards and prove/calibrate. I’ve seen for example a pressure test port aiming right at a wall with no clearance to connect.” Says Roy Tomalino, one of our training experts in the USA.

End-to-end vs. part testing

Proof testing of SIS components can be approached in two primary ways:

- End-to-end testing: This method verifies the entire Safety Instrumented Function (SIF) loop in one go — from sensor input to logic solver action to the final control element's response. It provides a realistic view of how the system behaves under actual conditions and helps identify integration issues between components.

- Part testing: In this approach, each component of the SIF — such as the sensors, transmitters, logic solver, and final element — is tested individually. While more flexible in scheduling, part testing requires careful planning to ensure no parts of the loop are overlooked.

Ideally, part testing should overlap or complement other component checks to ensure full loop coverage. Whether testing end-to-end or in parts, the goal is the same: confirm that every component performs as required and that the safety function will execute correctly when needed.

Calibration frequency requirements

There is no fixed “annual” calibration rule for SIS devices. Instead, intervals are set based on:

- SIL level,

- Failure rate data,

- Manufacturer recommendations,

- Historical device performance,

- Risk assessments.

Example intervals:

- SIL 1 → every 2–3 years,

- SIL 2 → every 1–2 years,

- SIL 3 → every 6–12 months.

Companies can sometimes adjust intervals based on performance data and risk analysis, but these decisions must be well-documented. Auditors increasingly expect companies to defend their calibration programs with evidence, not assumptions.

Regulatory oversight and auditing

SIS calibration records are regularly audited by:

- Regulators (e.g., HSE in the UK, OSHA in the USA, ADNOC in UAE, SAWS in China),

- Insurance companies as part of risk evaluations,

- Third-party certifiers like TÜV, Exida, or Lloyd’s Register,

- Internal corporate audit teams at global companies.

Auditors typically review calibration schedules, as-found/as-left results, test records, and management of change processes. Strong, traceable calibration programs are essential to pass these audits and maintain compliance.

Best practices and Beamex solutions

Effective SIS calibration programs include:

- Using high-accuracy, intrinsically safe calibrators like the Beamex MC6-Ex, which can handle multiple signal types in one device.

- Automating calibration management with Beamex CMX or LOGiCAL calibration management software to improve efficiency, reduce manual errors, and ensure a complete audit trail.

- Analyzing calibration data to detect drift patterns, optimize intervals, and improve performance. Check out Beamex CMX Analytics Dashboard.

- Integrating calibration and maintenance systems (e.g., SAP, Maximo) for better coordination. Take a look at Beamex business Bridge.

- Investing in technician training to build in-house expertise and ensure procedures are followed correctly.

Beamex delivers a comprehensive ecosystem of tools and services to help companies meet the demanding requirements of SIS calibration.

Conclusion

SIS and SIL are central to modern industrial safety programs. While design and technology are critical, it’s the ongoing calibration, proof testing, and maintenance that keep these systems reliable over their lifecycle.

A robust calibration program helps companies maintain compliance, reduce risk, improve performance, and protect their reputation.

Download free white paper

Download a detailed white paper that explores SIS, SIL, calibration strategies, global standards, regulatory frameworks, and best practices — all designed to help you strengthen your safety programs.

Download the detailed free white paper here >

Watch webinar recording

For those interested in deepening their understanding, we recommend watching the recorded webinar co-hosted by Beamex and the International Society of Automation (ISA), featuring functional safety expert Paul Gruhn. This session provides valuable educational insights into SIS fundamentals, standards, and real-world challenges.

Watch the webinar recording here >

Contact us for help

If you need any help managing the calibration and documentation of your Safety Instrumented Systems, don't hesitate to contact our experts >

.jpg)

.png)

Discussion