The so called "Smart" transmitters are getting ever more popular in the process industry, but what are these "Smart" transmitters and why do I say that also they must be calibrated?

That is what we will be discussing in this blog post. Besides that, we will also take a quick look at how to calibrate these transmitters.

What is a “Smart” transmitter?

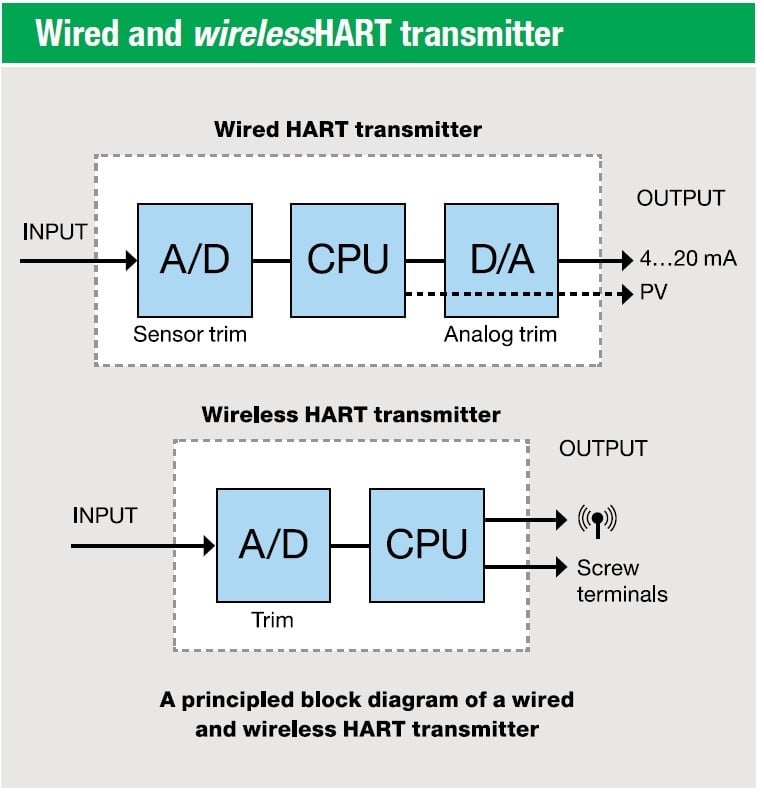

First, the use of the word “Smart” is not really standardized anywhere, so anyone can use it the way they want. Anyhow, it normally refers to a modern transmitter that is processor-based and has capability for digital communication. In this blog post the word smart means process transmitters that support HART, WirelessHART, FOUNDATION Fieldbus or Profibus protocols.

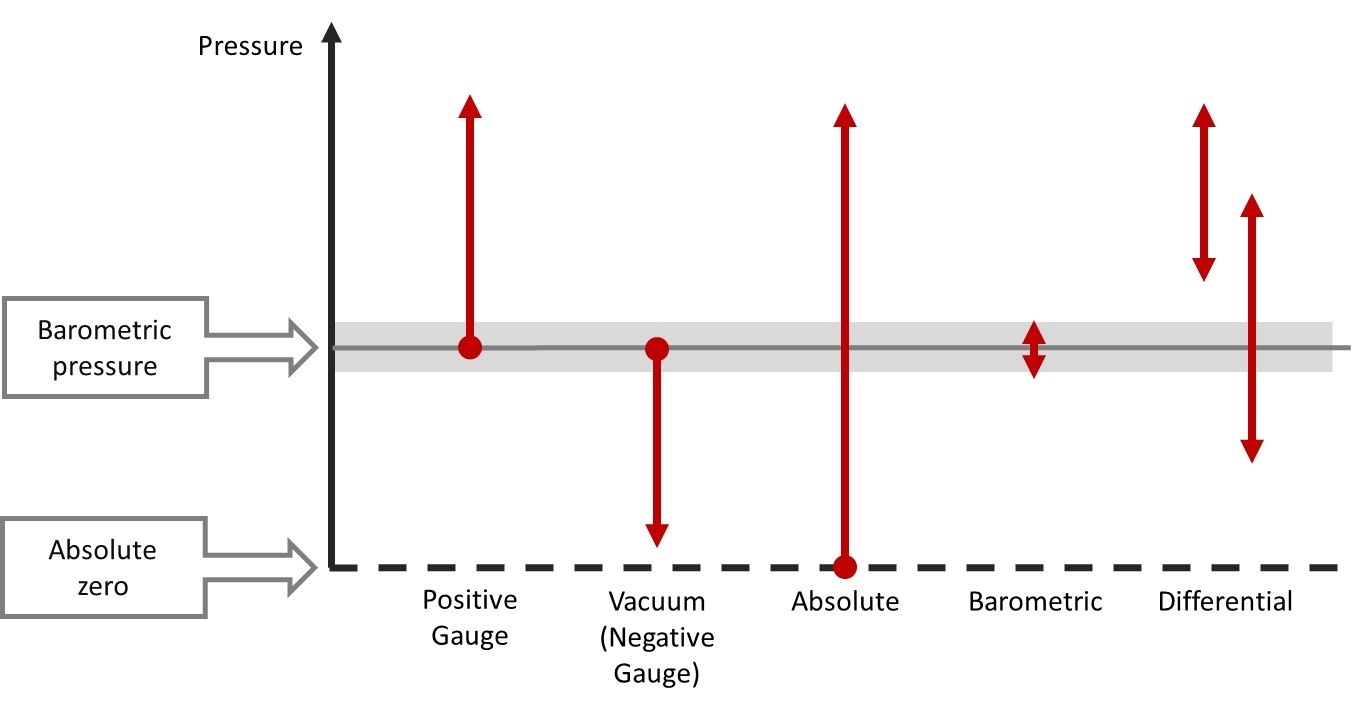

And since we talk about calibration, it also refers to transmitters that are measuring something and that are generally being calibrated, such as pressure, temperature, flow, level etc. transmitters.

How to calibrate a smart or non-smart transmitter?

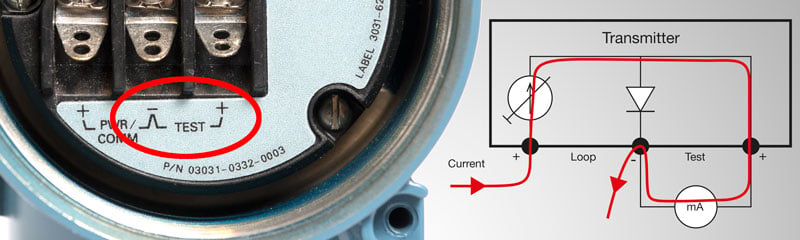

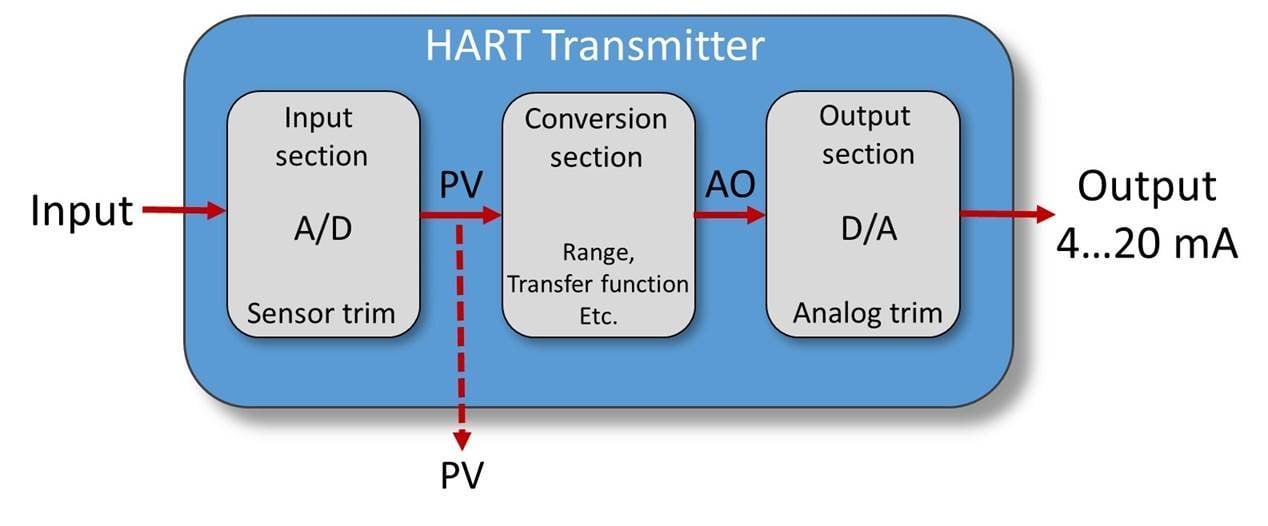

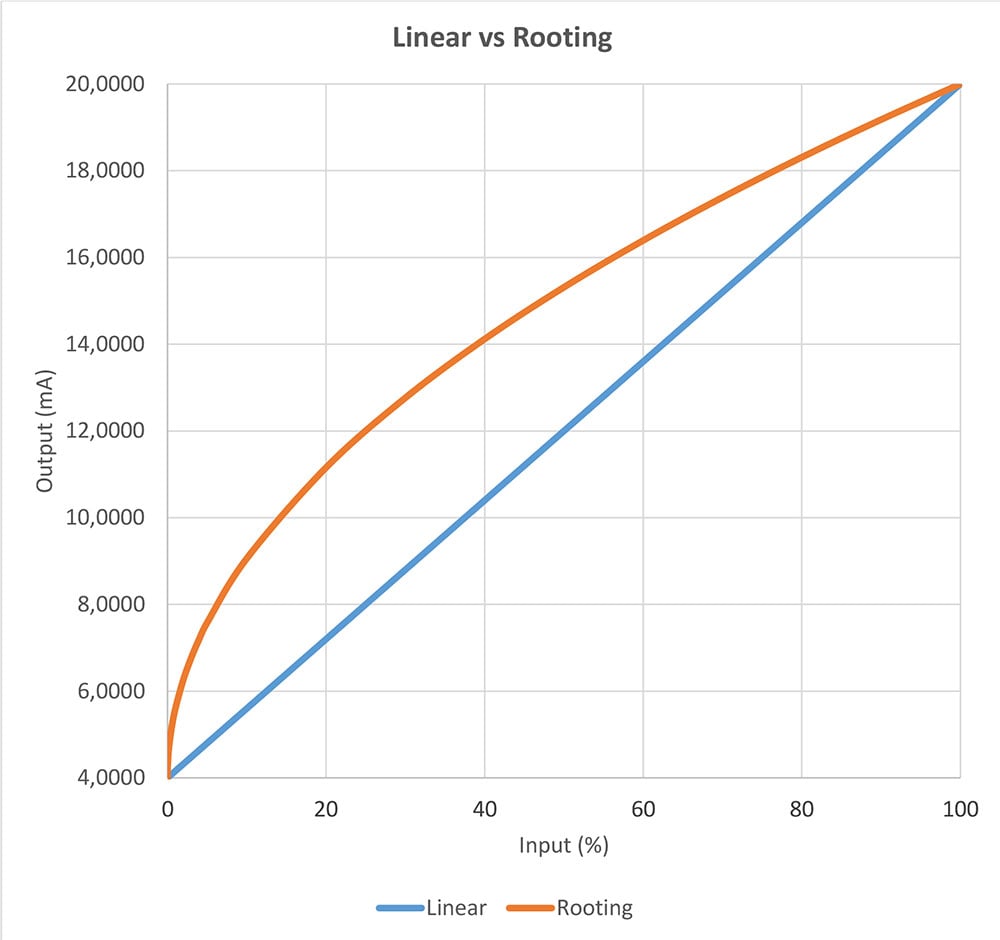

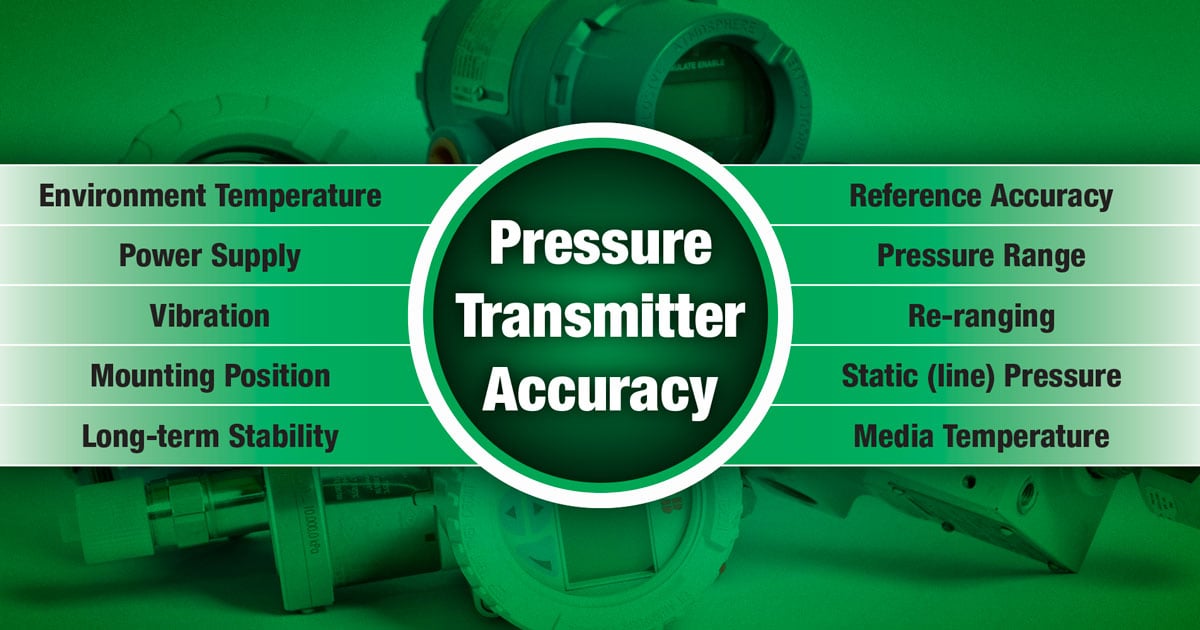

In order to do a metrological calibration on a transmitter, being an analog one or smart one, we want to check it’s accuracy to make sure that the conversion from input to output is correct. In practice we need accurate/traceable equipment (reference standard or calibrator) to generate/measure the input and to measure the output. We typically do this in a few points across the measurement range and document the results. If we find too much error, we need to adjust the transmitter in order to make it operate accurately.

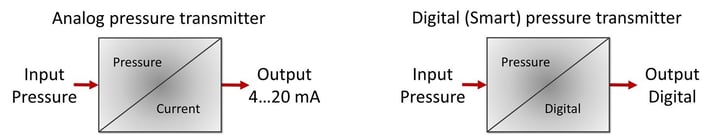

In case of a conventional analog transmitter the output is a mA signal which is easy to measure. But in case of a smart transmitter the output is digital, so we need to have some suitable device to read the digital output. Other than that, the calibration of analog and smart transmitters is very similar.

Whether the transmitter’s output is analog or digital, it does not change the purpose of the transmitter – to accurately convert input to output – and it does not change the fact that you need to calibrate it to make sure that it is accurate.

If we think about the whole measurement loop, an analog loop needs also A/D conversion in the control system end, which is another item to be calibrated in the loop. In case of digital smart transmitters, there is no need for such an additional conversion, as the digital output from the transmitter is sent to a control system.

A simplified principle diagram of a conventional analog and digital smart pressure transmitters:

Why calibrate?

As mentioned, the smart transmitter has digital output, but it still needs to be calibrated to make sure it is working accurately, i.e. converting the input to output correctly. Sure modern transmitters are getting more accurate and more stable than old transmitters, so they don’t necessarily need to be calibrated as often as the older ones.

But if you don’t calibrate your transmitter, it means that you don’t care if it is measuring correctly, so why did you buy and install the transmitter at all?

And if the transmitter sales guy is offering you new smart transmitters that don’t need to be calibrated at all, please forgive him, he is anyways just trying to reach his sales budget… ;-)

There are many reasons and motivations to make periodic calibrations, these are listed in the earlier blog post Why calibrate? (and the related White Paper) so please have a look at that to learn the most common reasons for calibration.

Configuration is not calibration!

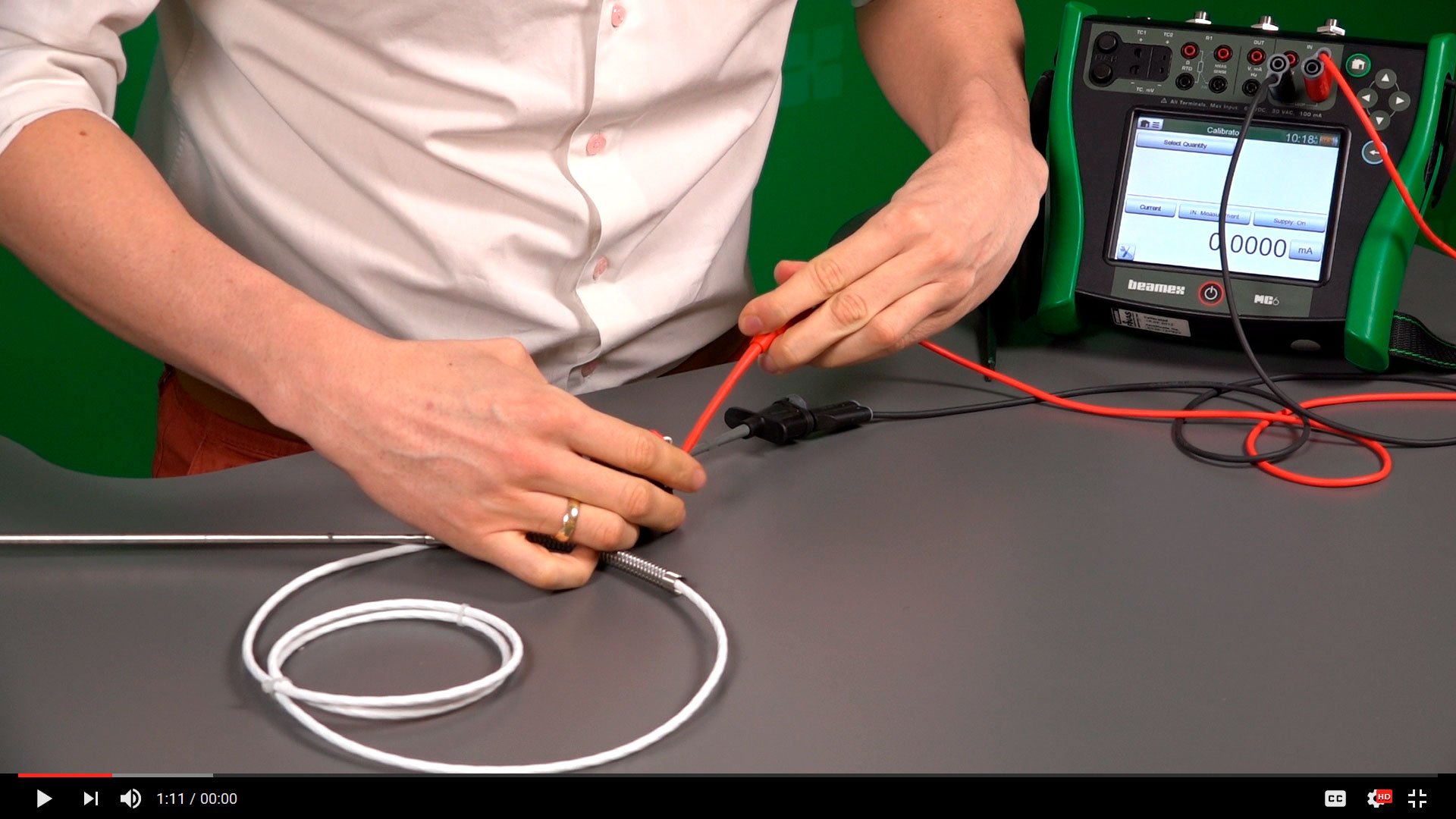

One great feature of modern smart transmitters is that they can be configured through the digital communication. Typically you use a communicator or computer with a suitable modem to do that. The configuration can also be done remotely from a long distance. With “configuration” I mean that you can view and edit various parameters of the transmitter. It is important to remember that if we talk about metrological calibration (i.e. process to check the transmitter accuracy), this cannot be done with a communicator only and remotely. For a proper calibration, you always need the accurate and traceable reference standard (calibrator).

If you are interested to see how you could use Beamex MC6 to calibrate different smart transmitters, have a look at some of these videos on our YouTube channel:

- How to calibrate a FOUNDATION Fieldbus transmitter

- How to calibrate a WirelessHART transmitter

- How to calibrate a Profibus transmitter

And of course if you have any questions or comments, please let us know.

I would also really like to hear your suggestions on topics you are interested in learning more about and that we should write about in this blog!

If you did read this far, great. Thank you and talk (or write) to you later.

Yours,

Heikki

Heikki Laurila is Product Marketing Manager at Beamex Oy Ab. He started working for Beamex in 1988 and has, during his years at Beamex, worked in production, the service department, the calibration laboratory, as quality manager and as product manager. Heikki has a Bachelor's degree in Science. Heikkis family consists of himself, his wife and their four children. In his spare time he enjoys playing the guitar.

.jpg)

.png)

Discussion