Pressure transmitters are widely used in the process industry. The advertised accuracy specification of modern pressure transmitters has become more and more accurate.

Often the advertised accuracy specification includes anyhow only part of the truth. It includes only some of the accuracy components effecting the total accuracy that you can expect from the transmitter in practice in your application.

In this blog post, I will examine some popular pressure transmitters’ accuracy specifications and the different accuracy components, such as effect of: re-ranging, ambient temperature, mounting position, static pressure, long term drift, vibration, power supply and more.

I will shortly explain what these components are and what they mean with a few examples.

Background

We see “number games” being played with some transmitters’ specifications, where they advertise an accuracy number that is just part of the truth, i.e. it is just one of the many accuracy components that you should take into account. In some cases, these advertisements can be confusing and give the wrong impression of the total practical accuracy you will get in your application.

Maybe the competition and race for the best accuracy numbers have led to this situation, that some manufacturers make a “limited” accuracy figure and put that on the cover of the brochure and advertise that on their web site, while the full specifications are found in the user manual.

Typically, a pressure transmitter’s specifications include several accuracy components that you should take into account when considering the total accuracy.

As mentioned, this blog post will review some popular pressure transmitter’s specifications to give you an idea of the kind of important factors you should take into account and be aware of. Also, I will list some typical specification numbers for the different partial accuracy components. I am by no means trying to put down or depreciate any transmitter.

As the transmitter accuracy affects the accuracy of your calibration equipment, we do also get these accuracy questions from customers. Certainly, the calibrator should be more accurate than the transmitter you calibrate with it, but the accuracy ratio between these two is something different people have different opinions on. Anyhow, you should be aware of the total uncertainty of the calibration and document that during the calibration.

The selection of your process transmitter’s tolerance should be anyhow based on the process requirements, not on the specifications of the transmitter that is installed in that location.

Time to dive into it…

Pressure transmitter accuracy components

“Reference accuracy”

Often there is a separate “limited” accuracy statement mentioned, typically on the cover of the brochure, or on the website.

This can be called “reference accuracy” or something similar, that includes only some parts of the accuracy, not all parts. It includes, for example only linearity, hysteresis and repeatability.

This “best-case accuracy” does not include all the practical accuracy components you should consider (mounting position, ambient temperature, etc.). So, don’t think that this specification is what you can expect in practice from the transmitter when you install it in your process.

This “best-case accuracy” may be for example 0.04 % or even 0.025 % of range, for the most accurate pressure ranges for the most accurate transmitters.

Different pressure ranges

Often the best (reference) accuracy is valid only for certain pressure ranges, not for all the ranges available. Also, it may vary on the pressure type, i.e. an absolute range may be different than a gauge range.

While the best ranges can have, say even a 0.04 % of range accuracy, some other range of that same transmitter model may have, for example, a 0.1 % accuracy.

Accuracy specifications may be doubled or tripled for the different pressure ranges available. So, make sure you know what the accuracy is for the exact pressure ranges/models that you are using.

Re-ranging

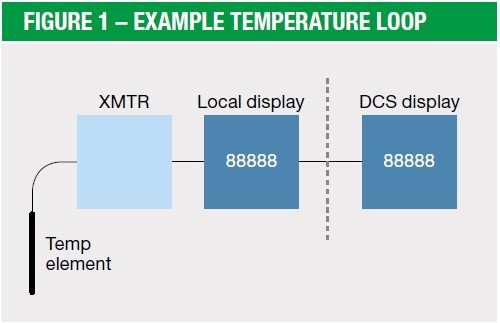

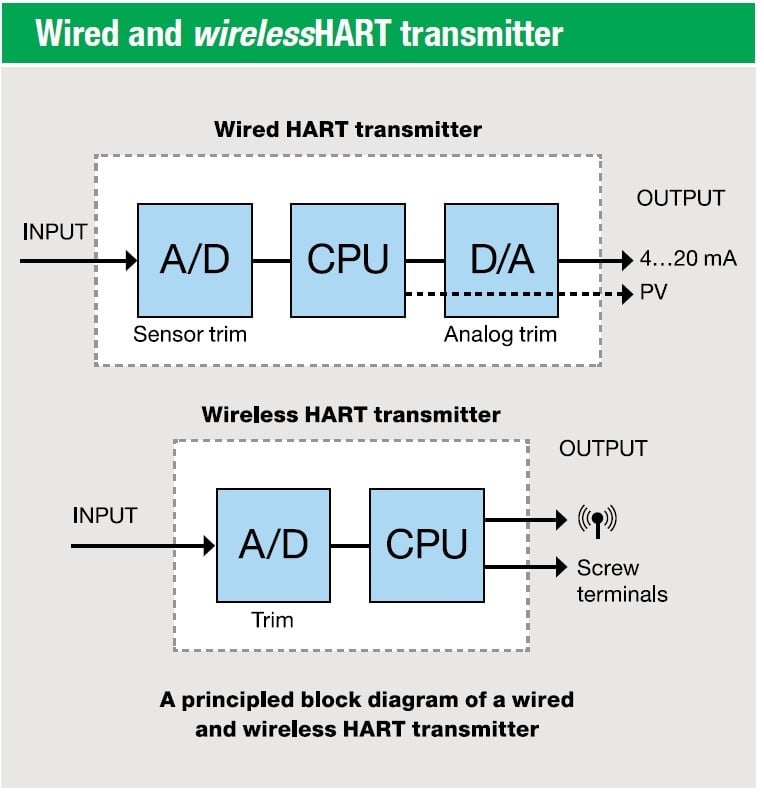

HART (smart) transmitters can be re-ranged with a wide ratio. Often you can re-range a transmitter with a turndown ratio of 100:1 or even more. Accuracy specifications are commonly given to the full range, or with a limited turndown ratio.

If the HART transmitter (with a mA output) is re-ranged for a smaller range than the full range, that typically worsens the accuracy. So, if you re-range your transmitter to a smaller range than the max range, please make sure you find if / out how much error that adds to the accuracy.

Ambient temperature effect

Most pressure transmitters are used in varying environmental conditions in the processes. Also, the temperature of the pressure media may vary widely during usage.

As with most measurement devices, pressure transmitters typically have some kind of temperature coefficient, i.e. there is an accuracy component that depends on the environmental temperature.

The temperature dependency seems to be often specified in a pretty difficult to understand format. But try to understand that and ask the supplier if you can’t figure that out.

Anyhow, looking at different transmitters, this may vary from say 0.01 % of range even up to 0.5 % of range. The worst models seem to specify the temperature effect being more than 1 % of the range.

If the temperature in your process varies a lot, you should take this into account.

Static (line) pressure effect

Differential pressure transmitters can be used under static line pressure conditions. This means that both inputs have a certain pressure and the transmitter is measuring the difference between the two inputs. Compared to a gauge transmitter that is measuring pressure against the atmospheric pressure or an absolute transmitter that measures pressure against full vacuum.

An ideal differential transmitter would measure only the difference between the inputs, but in practice, the common-mode static line pressure has some effect on the output.

If you have both inputs open to atmospheric pressure, the differential pressure is naturally zero. Also, if you have the same pressure (say 50 bar/psi) applied to both inputs the differential pressure is still zero. In practice, that static pressure has some effect to the transmitter output. So, the output changes a little when the line pressure changes.

Typically, the line pressure effect can go from 0.025 % of range up to 0.4 % of range, depending on the transmitter model.

Commonly, the line pressure changes mainly the zero of the transmitter, but does not make a significant change to the span. So, in calibration, you can test this effect by applying the same pressure (a low pressure and a high pressure) to both inputs and see how much the zero changes.

Line pressure may also have some effect to the span of the transmitter, which makes it far more difficult to handle and to calibrate. It requires a differential pressure standard for the calibration.

Long term stability

All measurement devices will slowly lose their accuracy over time. Some more, some less. That goes also for the pressure transmitters.

Some pressure transmitters have a 1-year stability specified, some have even a 5- or 10-year specification, or even longer.

For example, a transmitter that has a reference accuracy of 0.04% of range can have 1-year stability of 0.2% of range. Some other models have a similar 0.2 % of range level of specification valid for 5 or even 10 years.

The best one I found was as low as 0.01 % of range as a 1-year stability.

Depending on how often you re-calibrate your pressure transmitters, you should consider the long-term stability effect, as the transmitter may drift that much before the next recalibration (and possible trim).

Mounting position (orientation) effect

The mounting position typically has some effect on the accuracy of the pressure transmitter. Most pressure transmitters have a specification for the mounting position.

Typically, a change in the orientation changes the zero and does not affect the span accuracy. In practice, the orientation of the transmitter does not change during normal usage. The orientation should anyhow be considered if you first calibrate the transmitter in a workshop and then install it to the process, or if you remove the transmitter from the process for recalibration.

Certainly, if a transmitter has a remote seal, the location of the capillary tubes will have a big effect on zero value. Again, this is not something that does not change during normal usage, but may affect the calibration, if the transmitter is removed from its install location.

Vibration effect

Many pressure transmitters have a specification for the effect of vibration.

Naturally, this needs to be considered only if the transmitter is installed in a vibrating location.

The vibration effect to accuracy is often relatively small and can be, for example, specified of being “less than 0.1% of range.”

Power supply effect

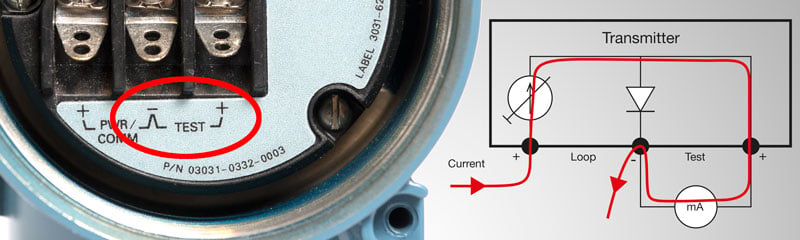

A 2-wire transmitter needs an external power supply to work. Typically, the power supply is a 24 VDC supply.

Transmitters can commonly work on a wide supply voltage range, going even down to 10 VDC.

Anyhow, if the supply voltage changes during the operation, that can have a small effect on the accuracy of the transmitter. The effect of the power supply voltage is typically small and can be specified of being “smaller than 0.01 % of span per 1 Volt change,” for instance.

In practice, if you have a normal good power supply, this is not an issue.

Total accuracy specification

Some transmitters have some kind of “total accuracy” specification that includes several of the common accuracy components. This can include the earlier mentioned “reference accuracy” and the ambient temperature effect and static/line pressure effect. This kind of total accuracy has a more user-friendly value as it is gets closer to the real accuracy you can expect from a transmitter.

As an example, the “total accuracy” specification can be 0.14 % of range, while the reference is 0.04 %.

So as soon as you include the temperature and line pressure effects, the reference accuracy gets multiplied by a factor of 3 to 4.

Another example model offers a 0.075 % of range reference accuracy, and when the temperature effect is included it raises to 0.2 %, and when static pressure effects are also included it goes up to 0.3 % of range.

If the transmitter has this kind of “total” accuracy specification, it helps you to get a more realistic picture of what kind of accuracy you can expect in practice. Even though that “total” accuracy is often still missing some accuracy components are listed here.

Contamination in usage

When a pressure transmitter is used in a process to measure pressure, there is a big risk that the transmitter’s membrane gets contaminated by the pressure media or some dirt. This kind of contamination can have a huge effect on the transmitter’s accuracy.

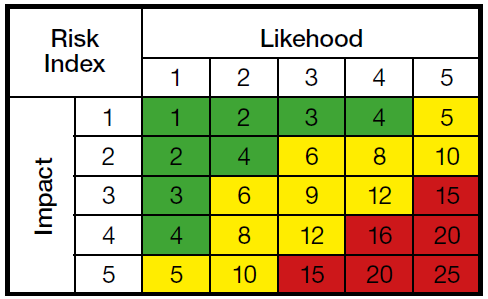

This is, of course, not something that can be specified, but is anyhow a big risk in normal use. Especially, if you decide to have a very long recalibration period, such as several years. So, in addition to the transmitter’s long-term drift specification, this should be considered in the risk analysis.

If the transmitter gets very dirty and starts to measure significantly wrong, you will normally see that in the measurement results. But if it only starts to measure a slightly wrong, it is difficult to notice in normal usage.

Best-case and worst-case examples

When you add up all the above listed different accuracy specifications, you come to the real total accuracy specification you can expect in practice.

Generally, when you combine independent uncertainty components, the common rule is to use the “root sum of the squares” (RSS) method. Just adding all components together as a straight sum would be a worst-case scenario and statistically, in practice, it is not very likely that all components will be in the same direction at the same time. Therefore, this statistical RSS method is used.

To get a best-case summary, we should take all the smallest accuracy components and neglect the ones that may not be relevant.

For the worst-case scenario, we should take all the accuracy components as their max and assume they are all present.

Best-case accuracy

To get the best-case accuracy, the following assumptions were used:

- Pick the best reference accuracy

- Choose the most accurate model and range

- Don’t do any re-ranging -> no effect to the accuracy

- Use the transmitter in a limited temperature range, close to ambient temperature. Pick the smallest available temperature effect.

- Assume no static/line pressure effect (used for gauge measurement) -> no effect.

- Assume no vibration effect -> no effect

- Assume a good power supply -> no effect

- Include a one-year drift

After reviewing the specifications for several different transmitters, it seems that the smallest combined accuracy I can find takes me down to around 0.15 % of range. For most other models it seems that the best case is around double that, so around 0.3 % of range at best.

There are also many models that have bigger best-case accuracy.

Worst-case accuracy

To find the worst-case accuracy, the following assumptions were used:

- Pick a model/pressure range with the biggest accuracy spec

- Assume some re-ranging happening

- Use the range with bigger temperature effect

- Assume static/line pressure being used

- Assume a small vibration effect

- Assume a small power supply effect

- Include a one-year drift

Again, looking at the different specifications, it seems that adding these worst-case accuracy specifications we end up somewhere around 1% to 1.5 % of range accuracy, with the most accurate transmitters.

But this figure can also go higher with some models.

Summary

As mentioned earlier, modern pressure transmitters are very accurate instruments. It is anyhow good to read the accuracy specifications carefully including all the different components that effect accuracy. It is easy to miss these and just look at the one accuracy, for example, “reference accuracy,” that is shown in marketing and other materials.

The purpose of this post is to raise your awareness on the different things that has an effect to the total accuracy you can expect in practice.

Of course, this same goes for all measurement equipment, not only for pressure transmitters. It is always good to read all specifications, including all the footnotes with small print.

I hope you found this article useful.

Beamex solution for pressure calibration

Beamex offers different solutions for pressure calibration, including calibrating pressure transmitters.

Please check out our offering here: Pressure Calibrators.

Related blog posts

If you found this article interesting, you might want to check these posts too:

- Optimal Calibration Parameters for Process Instrumentation

- How to calibrate pressure instruments [Webinar]

- How often should instruments be calibrated? [Update]

- How to calibrate pressure gauges - 20 things you should consider

- Pressure units and pressure unit conversion

- How to calibrate HART pressure transmitters [Video]

.png)

.jpg)

.png)

Discussion