You only live once: A common phrase used around the world to indicate how one should live their life to the fullest. This is a great concept for individuals to take advantage of the life they have been given, but to assure life for the future, resources and the environment should be taken into consideration in the process. In 1969, sustainability was introduced with the passage of the National Environmental Policy Act (NEPA), and has been an important topic ever since. Sustainable Plant Magazine defines sustainability as, “Operating our business in ways that meet the needs of the present without compromising the world we leave to the future.”

Social, economic, and environmental effects are the three pillars often used to define and measure sustainability. Calibration plays a critical role impacting these pillars to help maintain sustainability throughout plants. Calibrating process instruments on a regular basis aids in optimizing processes to minimize production downtime, ensure product quality and secure plant reliability. For many plants, calibration is also a critical activity in controlling emissions, as emission-related instruments are often associated with the plant’s license to operate.

The pillars of sustainability

Although social effects are hard to quantify and measure, they still play an important role in maintaining sustainability. Safety is one social factor that tends to be more quantifiable than others: Evident across many industries, plants often display the number of days without injury. Employee safety is a social factor that is every plant's responsibility.

A plant’s overall health and performance is important in protecting not only employees, but the community too. The community may not be directly impacted by on-the-job injury; however, poor maintenance and operations can lead to harmful impacts on the community, such as toxic gas emissions, out-of-spec products, or worst case scenarios, such as an explosion or poor product quality which leads to an injury or death.

Another social factor is the working and living conditions of the employees and community. Working conditions could include, working hours, industrial noise, plant temperature, and harmful toxin release. In some cases, employees are required to live where they work. An oil platform is a good example where social sustainability becomes even more important. Social sustainability is important in maintaining industrial performance for the future.

Economic sustainability in plant operations includes using available resources to increase performance with positive returns on investment and overall plant profit. Economic impacts are typically measured monetarily. If the return on investment is desirable, the plant can consider the resources justifiable. For example, if a calibration software solution helps monitor the overall instrument health of a plant which prevents unplanned shutdowns (that could cost millions of dollars), it is considered an economic solution to help maintain sustainability.

If available resources are not being used, the plant may not be sustainable in the future especially in competitive markets. In many of those situations, plant personnel do not understand what types of sustainable solutions are available and if they are right for a particular situation. Fortunately, many solution providers offer sustainability and return on investment reports to help distinguish sustainable solutions.

Although economic sustainability involves increasing plant profit by using available resources, the environment should not be compromised in the process. For example, if cheaper raw materials exist which improve overall profit but create harmful and toxic waste that compromise the environment, that solution is not considered sustainable. Environmental conditions must be considered in sustainable solutions.

Sustainability initiatives, regardless of the positive impacts on the social and economic pillars, all depend on the impact made on the environment, because ultimately, the future depends on today’s efforts to maintain a livable environment. Environmental initiatives could include many different projects to decrease negative effects on natural resources available today. One such project is developing paperless environments or digitalizing data to not only maintain trees and reduce waste, but also to create a more economical solution that decreases time spent performing work. Other projects include the design and construction of green buildings that use less energy and water, manufacturing process modification that reduce greenhouse gas emissions that destroy the atmosphere, and restoration of different aspects of the environment that have been destroyed in the past, such as greenery and natural streams and rivers.

Different governmental agencies and acts, such as those from the EPA, OSHA and NEPA, have set regulations to help advance sustainability initiatives that promote positive influence on the social, economic, and environmental aspects indicating the importance of sustainability to ensure a future for this planet.

Impact of calibration on plant sustainability

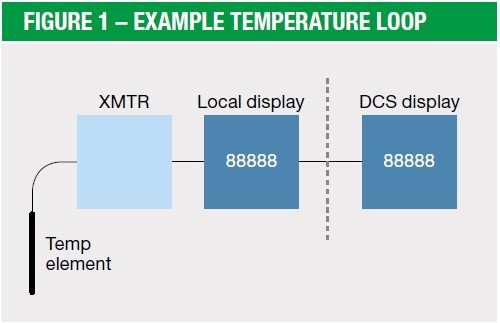

Process instrumentation exists to monitor how much, how high, how little and how often, contents are being used to create a product. Calibrating process instrumentation adheres to the social, economic, and environmental pillars of sustainability. As mentioned above, social sustainability includes the safety of the employees and community. For example, toxic gas emissions are monitored by process instrumentation which must be calibrated and the results documented to ensure accurate readings required by regulatory agencies, such as the EPA and OSHA.

Using a calibration software can help improve plant sustainability in many ways. For instance, calibration software can remind plant personnel when instruments are due for calibration, reducing the chance for these instruments to be overlooked, which if not calibrated could be out of tolerance, causing the process to emit harmful chemicals into the atmosphere which could negatively affect the environment and be deadly or harmful to the community. Calibration helps to ensure proper function, reliability and accuracy of instrumentation.

An automated, integrated calibration program can integrate with maintenance management systems (MMS), to help increases quality and decrease the time and money spent on calibration, especially when compared to manual systems, such as pen and paper. Many plants receive work orders from the MMS queuing them to perform calibration. Traditionally, results were written down using paper and pen then inserted into several databases, once in a calibration database and once in an MMS. This manual process can take hours of work and is prone to errors, while a calibration software saves a considerable number of man-hours and enhances data integrity. Streamlined calibration processes have fast returns on investment and secure plant profit by catching potential failures before they cause unplanned shutdowns, thus making a plant more sustainable for the future.

Beamex solution

Not only does calibration promote sustainability, but Beamex calibration solutions are manufactured with sustainability in mind as well. Beamex’s product development and production teams have received training on the environmental impact of product design. Beamex products are also designed to have a long operating life – typically a customer uses a Beamex calibrator for over ten years. This minimizes the waste generated from the products.

The Beamex production process follows the Waste Electrical and Electronic Equipment (WEEE) directive 2002/96/EC that sets collection, recycling and recovery targets for electrical goods and is part of a European Union legislative initiative to solve the problem of huge amounts of toxic electronic waste. Beamex also takes into consideration the Eco Vadis and ISO 14001 environmental standards in their ISO 9001 quality system.

References

Larson, Keith. “Why Sustainability Now?” Sustainable Plant. Putnam Media. 2013. Web. 26 March 2013. <http://www.sustainableplant.com/about-us/

.png)

.jpg)

Discussion