The ISO9001 standard was revised in 2015. In this blog, I will examine the main changes. And as I am madly interested in calibration, I will mostly concentrate on the changes that will affect your calibration processes, if you are an ISO9001 certified company or are applying the standard.

The ISO9000 series is the most popular quality management standard. It was initially published almost 30 years ago, in 1987. We received the ISO9001 certificate for Beamex back in 1992 when I was working as Quality Manager. It was all pretty new then and it was the first revision of the standard used. Since then, the standard has been revised several times, in 1994, 2000, 2008 and 2015. While 2008 revision was considered pretty minor, the 2015 revision was a more major one. As usual, certified companies have a 3 year transition period to update their quality system to meet the new revision.

Main changes in brief

Below is a short list including some of the main changes in the new revision:

- The high level structure (HLS) of ISO90001 has been updated to the common structure of other ISO standards, such as the ISO14000 environmental standard.

- An important fundamental higher level update is that the term “management” has been replaced with “leadership.” This is a pretty big modernization to the thinking.

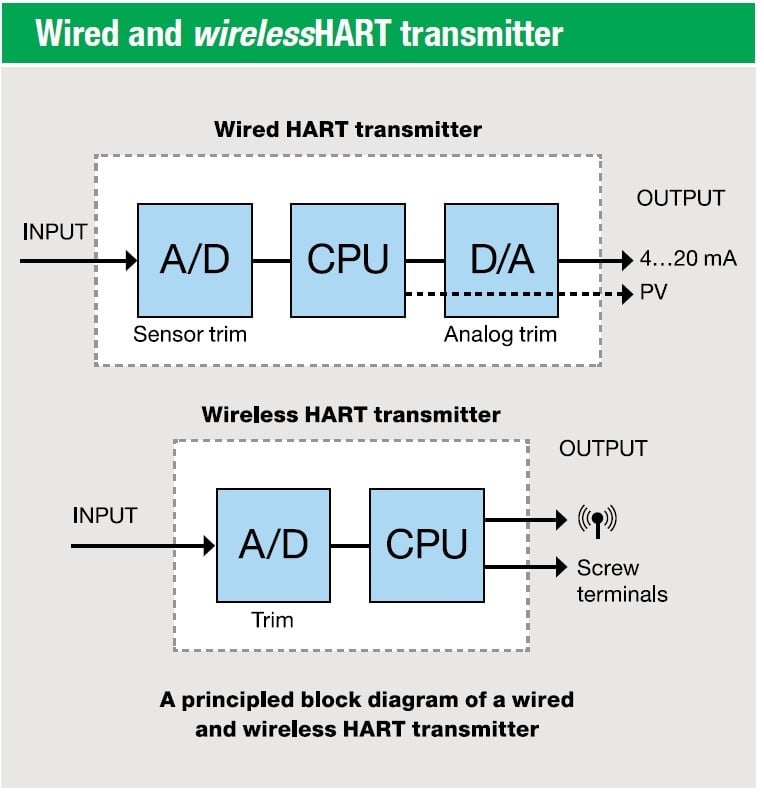

- The older version of standard had a dedicated chapter for test and measuring equipment; the new revision distributes this into the higher level chapters, setting requirements on human and equipment resources. So, this is not as specific and easy to interpret as before. But on the other hand, it requires you to think about the bigger picture.

- Finally, the risk-based thinking approach is a big change that has been added throughout the standard. Pretty much, this changes the way the standard is to be applied. This is also one of the biggest changes in the standard that will affect the calibration processes. Therefore, next I will look into some basics for risk-based thinking and discuss some practical calibration-related risks.

Risk-based thinking

Sure, the risk-based thinking may be familiar to many of you from other standards and other occasions. Although the idea is to find and evaluate the risks, it is good to remember that it also helps to reveal new opportunities.

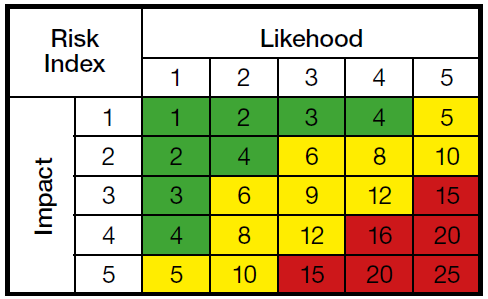

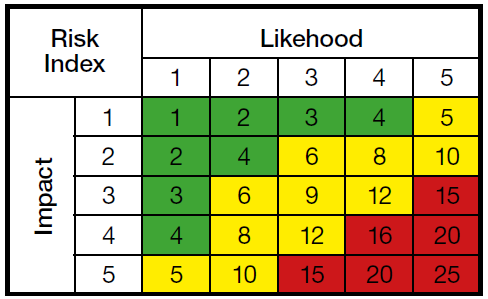

Risk index

When risks are evaluated, a tool often used is a risk index. It is a systematic way to first evaluate the impact/severity of something happening and the likelihood of that to happen. You determine a rating for impact and likelihood, then multiply these and you will get a risk index. Often impact and likelihood are rated on 1 to 5 scale, so you will end up with a 1 to 25 risk index. The bigger the index, the bigger the risk. Maybe a picture explains it better.

The green, yellow and red indicate low, medium and high risk. For further study, there is for example a dedicated ISO31010:2009 standard for risk management/assessment.

Risk-based thinking in calibration

So how do you apply this risk-based thinking to your calibrations? Obviously, the updated standard does not give you any direct answers, but it demands you to make the required analyses. Now, I will very briefly list a few practical things I think should be considered to minimize risks in calibrations:

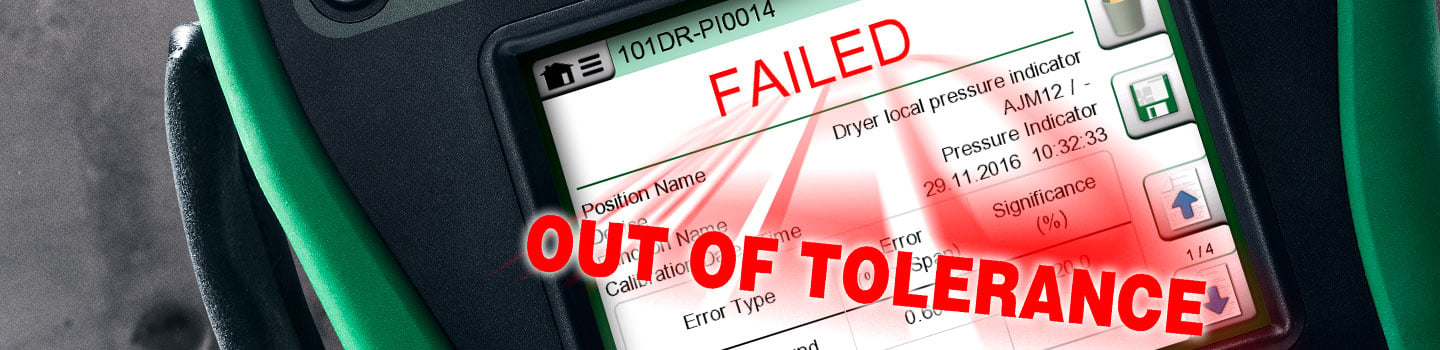

Importance of each measurement

Analyze and determine which are the most important measurements in your site are. For critical measurements, install better measurement devices, calibrate them more often, analyze the consequences of an out-of-tolerance situation, use tighter pass/fail limits, and adjust even when there is small error, although not close to limits, etc. Even if your resources are limited, you should use them on the most important calibrations.

Base acceptance limits on the real need

Make sure the pass/fail limit of each measurement is based on the real process need and don’t just use the transmitter manufacturer’s specs for each installed location.

Eliminate all manual entry of results

Avoid any manual entry of calibration results. Use documenting calibration equipment that transfer the results to your calibration software automatically.

Automate error calculation and Pass/Fail decision

Manually calculating error and comparing it to acceptance limits can be a very error prone task. Implement systems that make this calculation for you.

Analyze drift over time

When you analyze the drift of each instrument over time, you will be equipped with valuable data on its stability, and can adjust the calibration period accordingly. Avoid making unnecessary calibrations (still remembering the costs and consequences of an out-of-tolerance situation).

Always be aware of total uncertainty

Don’t just use device A to calibrate device B using process C and be happy if the numbers look good. Instead, always be aware of the total uncertainty of the calibration, including the different uncertainty components coming from equipment and process.

Automate as much as possible

Try to automate your calibration process as much as possible because this makes the process repeatable and minimizes the risk of human errors.

Summary

This latest revision of the ISO9001 standard is more suitable for modern thinking. The changes may not be so easy to implement, as it takes some thinking and possibly workflow adjustment to accomplish them. This was a very short summary written on this subject. So, if you want to learn more, download the white paper below.

Yours in blog,

Heikki

Heikki Laurila is Product Marketing Manager at Beamex Oy Ab. He started working for Beamex in 1988 and has, during his years at Beamex, worked in production, the service department, the calibration laboratory, as quality manager and as product manager. Heikki has a Bachelor’s degree in Science. Heikkis family consists of himself, his wife and their four children. In his spare time he enjoys playing the guitar.

Eveything you need to know about how the ISO9001:2015 standard affects calibration, in one white paper. Read it now!

.jpg)

.png)

Discussion