I wanted to write about a topic that is often discussed yet poorly understood: using a HART communicator to calibrate and adjust a HART transmitter. Many believe that you can use a HART communicator to calibrate and adjust HART transmitters, but this is not the case. You always need a calibrator (or some form of traceable reference standard) for transmitter calibration. Why is that, and what are the differences between a HART communicator and a HART calibrator? These and many other related topics are discussed in this blog. If this sounds interesting, please keep reading.

Download this article as a PDF file >>

Table of contents

- "Calibration" definition

- HART protocol

- HART transmitter

- HART communicator

- HART calibrator

- HART communicator versus HART calibrator

- HART transmitter calibration video

- Common mistakes and how to avoid them

- Summary

- Beamex solution

"Calibration" definition

First, in this (or in any) context, when I talk about calibration, I mean a traceable metrological calibration where you compare the device under test (DUT), e.g. a transmitter, against a more accurate, metrologically traceable reference standard, often called a calibrator, and document the results.

This is according to the international definition of calibration by the Bureau International des Poids et Mesures (BIPM). You can also refer to our “What is calibration?” page.

Please note that sometimes the word calibration is also used to describe the process of changing transmitter parameters or adjusting an instrument, or for some other purpose. This may be confusing. So, when you hear people talk about calibration, please check what they mean.

HART protocol

I’m assuming that most readers are familiar with the HART protocol, but here’s a brief summary for those who need reminding what it is:

The Highway Addressable Remote Transducer (HART) protocol is a widely used communication standard in process automation industries, enabling simultaneous analog and digital data transfer over the same wires. HART enhances legacy 4–20 mA analog signals by superimposing a digital signal over the top of the analog signal using frequency shift keying (FSK). This makes HART transmitters compatible with existing analog control systems while providing advanced digital communication capabilities for diagnostics, data access, and configuration.

For more detailed information about the HART protocol, please check FieldComm Group’s explanation.

HART transmitter

Next, let’s discuss the structure of a HART transmitter.

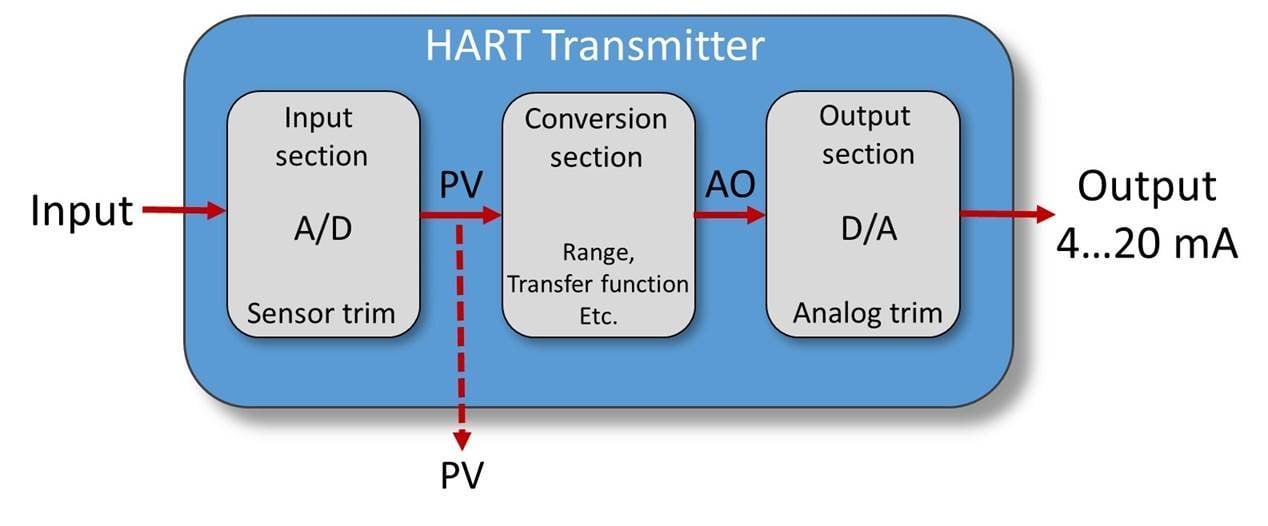

The image below illustrates the structure of a HART transmitter.

Here is a brief explanation of the above image:

- In the input section the actual measured signal (pressure, temperature, flow, etc.) goes into the A/D converter, which converts the analog input signal into digital format. The most commonly used variable is the primary variable (PV). The input section can be adjusted/trimmed using the sensor trim function in the transmitter.

- The digital PV signal then goes through a conversion module, where it can be converted in different ways. You can configure the range of the transmitter (the input value that corresponds to 4 and 20 mA output), transfer function, damping, and many other settings. This configured output, marked as AO (analog output) in the image, is the digital representation of the analog mA output. Please note that the AO is still in digital format; it is not the actual analog output of the transmitter.

- The digital AO signal then goes to the output section, a D/A converter, that converts the digital signal into an accurate analog mA signal. The output section can be adjusted/trimmed using the analog trim function.

- The accuracy of a HART transmitter depends on all these sections because they are in series.

For more information on HART transmitters, please refer to this older article: Calibration of a HART transmitter and the most common misconceptions about a HART communicator

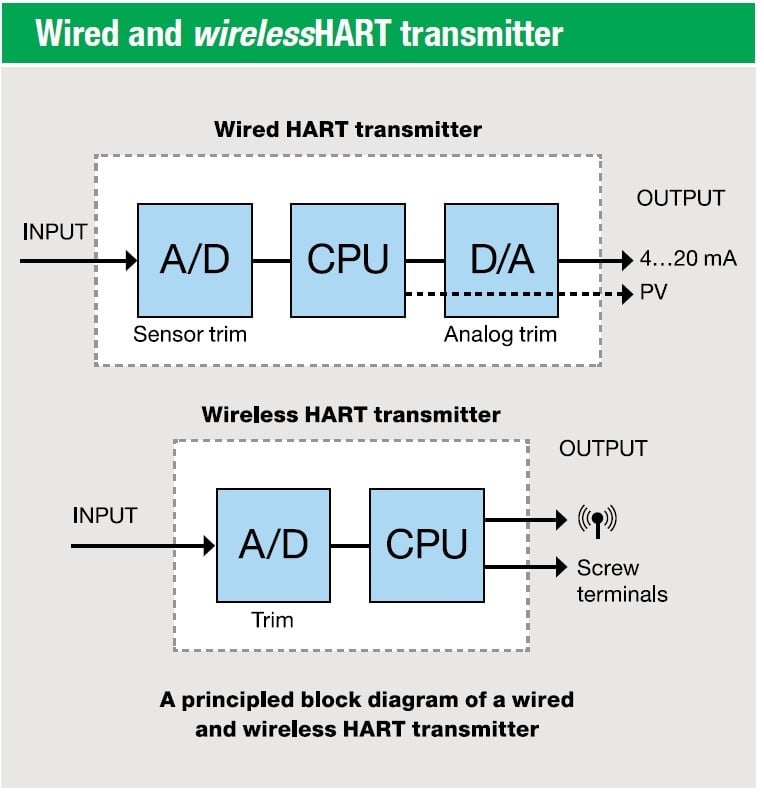

Another related article discusses why and how to calibrate WirelessHART transmitters.

HART communicator

A HART communicator is a portable device that can communicate with HART transmitters. The communicator can be used to configure and edit parameters in different HART transmitters, assuming it has proper device description (DD) files. Basic support can be achieved with generic HART commands, but if you want to be able to support all functions you need to have the DD file for the transmitter model and version that you are using.

Popular HART communicators include Emerson 475 and Trex, Yokogawa, Meriam and more.

Typically a HART communicator is not capable of generating or measuring any process signals, at least accurately enough for calibration purposes. So, if you want to calibrate or trim the transmitter, you will need to use a separate calibrator.

One confusing thing is that a HART communicator can read the analog output (AO) signal, which is the digital representation of analog mA output. It shows an mA value, so it might seem that you can measure the actual analog mA output signal of the transmitter, but that is not the case.

As we saw in the image earlier, the AO signal still goes though the analog output section, which converts the digital AO signal into a real analog mA signal that is then the actual analog mA output of the transmitter that goes to the control system.

The actual mA output signal of the transmitter is not the same as the digital AO signal you can read with your communicator. This often surprises people when they measure the actual mA signal with an accurate calibrator and notice that it is not the same as the digital AO signal. In some cases, people have even neglected the actual calibration and trusted the digital AO signal read with their communicator.

Please remember that if you use a HART communicator, you will also need to have a separate process calibrator if you want to do any accuracy-related activities such as calibration or trim.

HART calibrator

In this article I use the term HART calibrator to refer to a piece of equipment that includes an accurate process calibrator and a HART communicator in one device.

With the HART communicator section you can do all the HART communicator activities, and with the process calibrator section you can perform accurate traceable calibration of the transmitter.

For example, you can use a HART calibrator to:

- calibrate the transmitter from the input signal to the output signal

- calibrate and trim the input section of a HART transmitter

- calibrate and trim the output section of a HART transmitter

HART communicator versus HART calibrator

In a normal process plant you commonly have a lot of HART transmitters. This means that you will need to do configurations and calibrations – and you’ll need tools for both. You can either use separate tools (a communicator and a calibrator) or an integrated tool (a device that includes both a communicator and a calibrator).

One of the main benefits of using an integrated tool such as the Beamex MC6 Advanced Field Calibrator and Communicator is that you only need to carry one device with you. Also, when you are trimming a HART transmitter you need to enter the readings from the calibrator into the communicator, and with the MC6 you can easily just copy-paste. If you use separate tools, you will need to manually read the calibrator reading and enter that into the communicator.

HART compatible loop supply

It is good to remember that when you work with HART transmitters, you will also need to have a HART compatible loop supply for the transmitter to operate. While calibrators typically include a built-in loop supply, this is not the case with all HART communicators. So, you may end up needing a separate loop supply to get the transmitter working. And the supply needs to be HART compatible, i.e. it needs to include a suitable impedance (nominally 250 Ohms) for HART communication to work. If you use a HART calibrator with a HART compatible loop supply you won’t need additional impedance. In some cases you may be able to use the supply from the control system.

HART transmitter calibration video

To see how to calibrate and trim a HART transmitter, please check out this video:

In this video, Mike is using the Beamex MC6 and first uses the calibrator to calibrate a HART pressure transmitter, finding out that it is out of the allowed tolerance, i.e. the error is too large. Mike then adjusts the transmitter by performing both sensor trim and analog trim using the MC6’s HART communicator and calibrator functionality. Finally, he calibrates the transmitter and finds it well within the allowed tolerance limits.

If you performed these tasks using a HART communicator you would need an additional calibrator for the pressure and current signals. You would also need a HART compatible loop supply. And you would need to manually transfer the readings between the calibrator and communicator. Not to mention that you would need to carry at least two devices with you.

Common mistakes and how to avoid them

Finally, here’s a short list of some common mistakes made when using HART communicators and HART calibrators along with some suggested solutions.

- Confusing configuration with calibration

- Mistake: Believing that configuring or editing parameters in a HART transmitter using a HART communicator is equivalent to calibrating it.

- Solution: Use a traceable calibrator to ensure accuracy and compliance with standards.

- Trusting the digital AO signal as an accurate output measurement

- Mistake: Assuming that the digital analog output (AO) signal read by a HART communicator accurately represents the actual analog mA signal.

- Solution: Understand that the digital AO signal is different from the true analog mA output and use an accurate calibrator.

- Not using a suitable loop supply

- Mistake: Attempting to calibrate or configure a HART device without providing a HART-compatible loop supply, leading to communication issues.

- Solution: Use a HART calibrator with a built-in loop supply or ensure proper external supply with compatible impedance.

- Manual entry errors when using separate tools

- Mistake: Manually transferring readings between separate communicators and calibrators can introduce errors.

- Solution: Use integrated tools like HART calibrators that allow direct data transfer or copying.

- Skipping sensor and analog trim steps

- Mistake: Assuming that once a transmitter is configured, no further calibration or trimming is needed.

- Solution: Calibrate transmitter and perform sensor trim and analog trim if necessary.

- Relying on outdated DD files

- Mistake: Using a HART communicator with outdated device description (DD) files, potentially limiting functionality or compatibility.

- Solution: Regularly update DD files from reliable sources to ensure compatibility with new devices and features.

- Overlooking calibration documentation

- Mistake: Neglecting to document calibration results, which may lead to non-compliance or poor traceability.

- Solution: Use documenting calibrators and calibration software to digitally store and manage calibration data.

Summary

In the maintenance and calibration of HART transmitters, you will need to use both a HART communicator and a process calibrator. It is up to you whether you use separate devices or a device that includes both a communicator and a calibrator.

Personally, I prefer a device such as the Beamex MC6 because it includes both.

Below is a summary of the main functionality differences between a HART communicator and a HART calibrator:

| Functionality | HART communicator | HART calibrator |

| Read and configure HART device parameters | ✓ | ✓ |

| Calibrate process signal (e.g., mA, pressure) | - | ✓ |

| Generate accurate process signals for testing and calibration | - | ✓ |

| Adjust transmitter input section (sensor trim) | - | ✓ |

| Adjust transmitter output section (analog trim) | - | ✓ |

| Access and use Device Description (DD) files | ✓ | ✓ |

| HART compatible loop supply | Typically not | ✓ |

| Document calibration results | Typically not | ✓ |

| View and modify device diagnostics | ✓ | ✓ |

| Integrate HART communication with calibration | - | ✓ |

| Measure and display analog mA signals accurately | - | ✓ |

Beamex solution

The Beamex MC6 Advanced Field Calibrator and Communicator family includes calibrators with an optional HART communicator built-in, including a HART compatible loop supply.

With MC6 family devices the communicator and calibrator are physically integrated into the same device and can communicate with each other, meaning their functionalities are integrated too.

And because the MC6 is also a documenting calibrator, it will document your calibrations digitally so you can easily transfer the results to your calibration management software.

The HART DD files of MC6 family devices can be updated free of charge from the Download Center on the Beamex website. DD packages are regularly updated when new DD files are published by FieldComm Group.

In addition to HART protocol support, MC6 family devices also support FOUNDATION Fieldbus and Profibus PA communication.

For potentially hazardous environments, we offer the MC6-Ex Intrinsically Safe Advanced Field Calibrator and Communicator. The MC6-Ex combines a communicator and a calibrator in one intrinsically safe device, which is a rarity on the market.

View all Beamex HART communicator products.

Request a product demonstration >

Find your local Beamex partner >

Download a free white paper

Download a free white paper by clicking the image below:

.jpg)

.png)

Discussion