TOPIC

calibration period

Apr 24, 2019

Optimal Calibration Parameters for Process Instrumentation

Many calibration technicians follow long-established procedures at their facility that have not ...

Jan 30, 2018

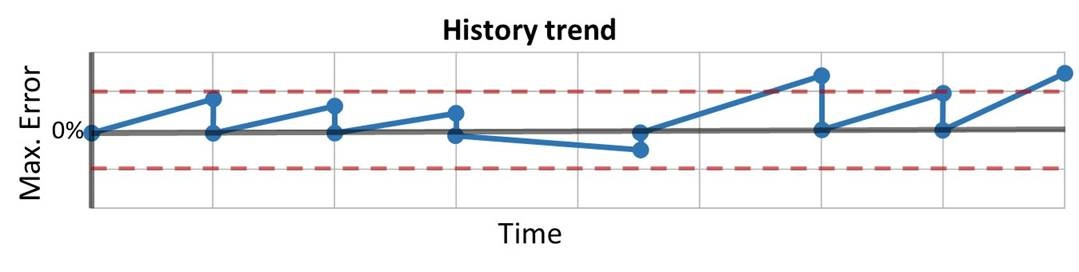

How often should instruments be calibrated? [Update]

How often should instruments be calibrated? That is a question we get asked often. It would be nice ...