We quite often receive questions regarding the calibration of a square rooting pressure transmitter. Most often the concern is that the calibration fails too easily at the zero point. There is a reason for that, so let’s find out what that is.

First, when we talk about a square rooting pressure transmitter, it means a transmitter that does not have a linear transfer function, instead, it has a square rooting transfer function. When the input pressure changes, the output current changes according to a square rooting formula. For example, when the input is 0% the output is 0% of the range, just as when

So, why and when would you use that kind of transmitter? It is used when you are measuring flow with a differential pressure transmitter. In case you have some form of restriction structure (orifice/venturi) in your pipe the bigger the flow is, the more pressure is generated over that structure. When the flow grows the pressure does not grow linearly, it grows with a quadratic correlation.

If you want to send a mA signal to your control room, you use a square rooting pressure transmitter that compensates for the quadratic correlation - and as a result, you have a mA signal that is linear to the actual flow signal. You could also use a linear pressure transmitter and make the conversion calculation in your DCS system, ISO-5167 gives more guidance.

So, what about when you start calibrating this kind of square rooting transmitter?

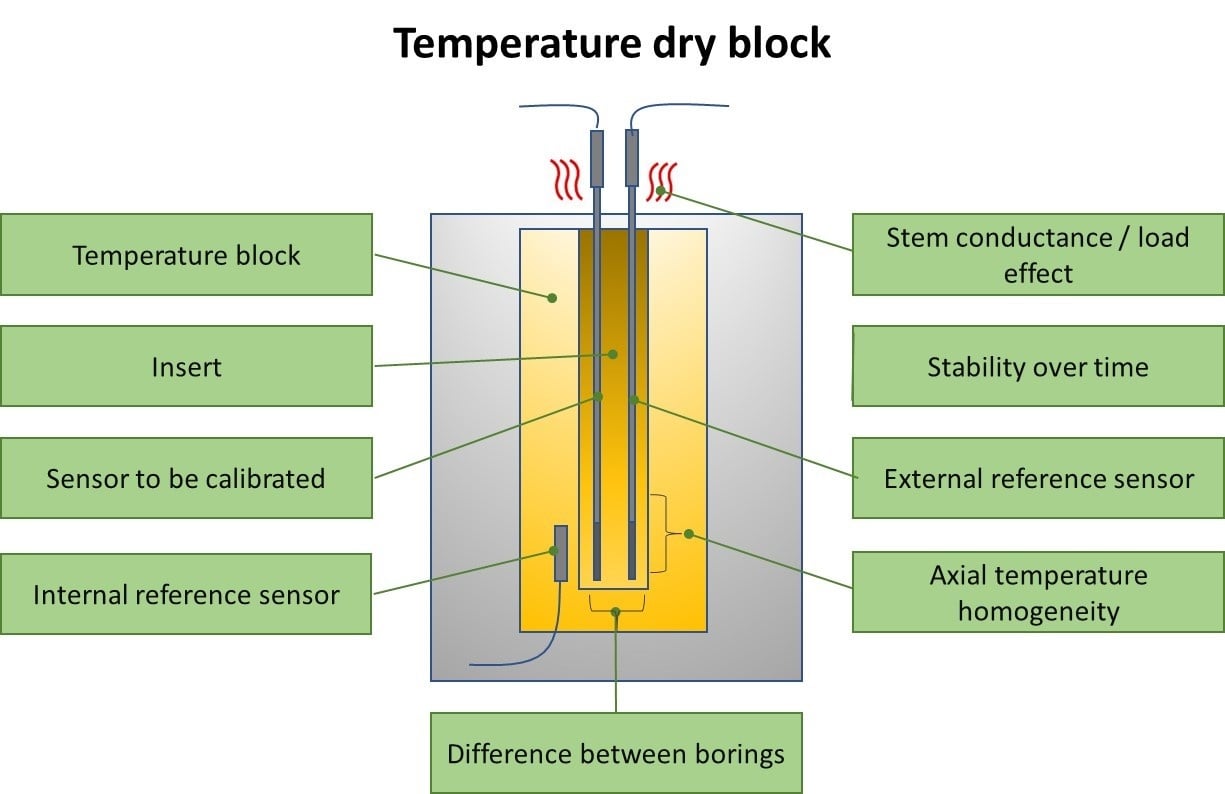

You can, of course, calibrate it in a normal way, by injecting a known pressure

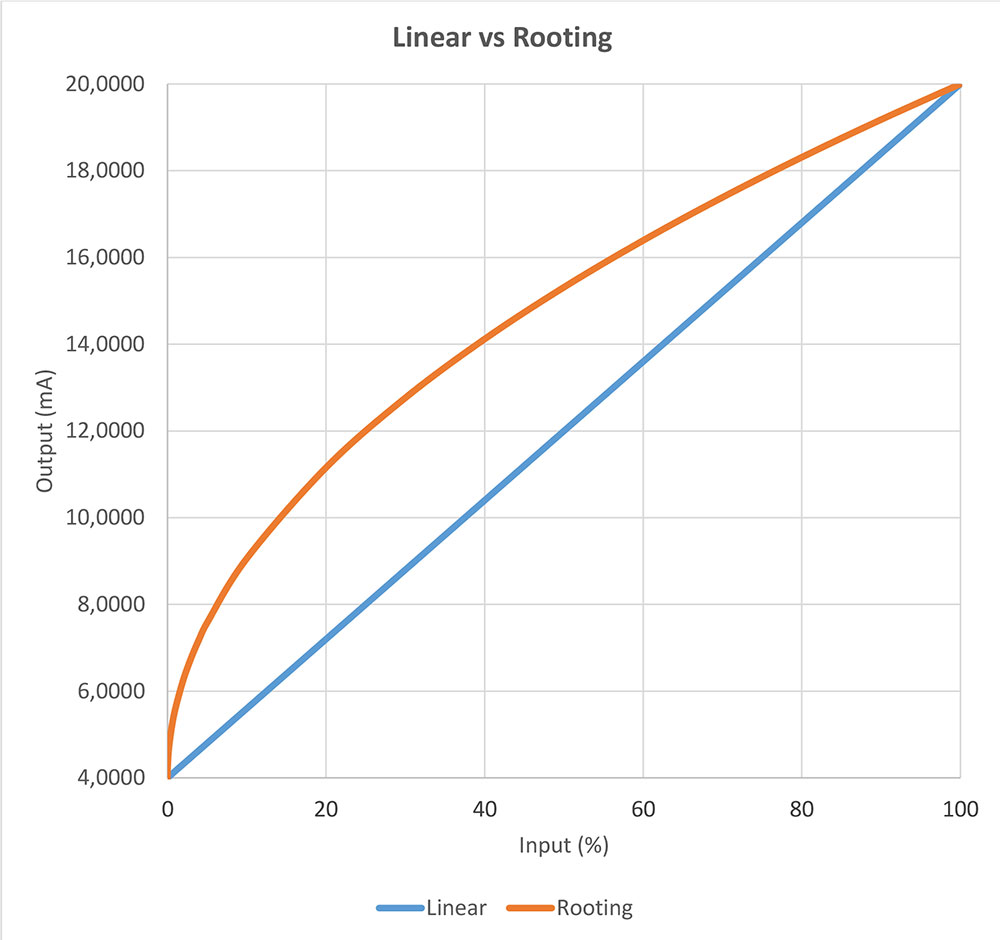

Figure 1. Linear versus square rooting.

Figure 1. Linear versus square rooting.In practice, this means that if your input pressure measurement fluctuates just one or a few digits, the output should change a lot in order for the error to be zero. What happens is that if the measured values

So what to do? In order to calibrate, you should simply move the first calibration point a bit higher than 0% of the input range. If the first calibration point is at 5 – 10% of the input range, you are already out of the steepest part of the curve and you can get reasonable readings and error calculation. Of course, then you don’t calibrate the zero point, but your process is normally not running at zero

I hope this short explanation made some sense and helped with this issue, let me know if you need any further explanations!

Yours truly,

Heikki

Update, Feb 2018:

How to calculate the output?

There have been some questions on how to calculate the output mA of a square rooting pressure transmitter.

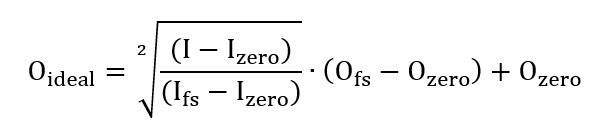

Below is a formula that you can use to calculate what the output current should be at a given input point:

Where:

| is the theoretical output value at the measured input for a calibration point (I). | |

| I | is the measured input for a calibration point. |

| Izero | is the theoretical input value at Input 0%. |

| Ifs | is the theoretical input value at Input 100% (full scale). |

| Ofs | is the theoretical output value at Output 100% (full scale). |

| Ozero | is the theoretical output value at Output 0%. |

Heikki Laurila is Product Marketing Manager at Beamex Oy Ab. He started working for Beamex in 1988 and has, during his years at Beamex, worked in production, the service department, the calibration laboratory, as quality manager and as

.jpg)

Discussion