When you work with something, it's so much easier if you have the proper tools, right?

The same goes for calibration – if calibration is your job, you want the best tools to make your work easier and help you to get more done. Modern calibrators ensure that your calibrations are accurate, you have less to carry, are easy to use, there are automated functions, and so on.

However, when you ask your boss to buy you a new calibrator, you need good arguments. Often, what is important to you may not be as important to your boss. So, you need to be clever and speak “boss language”, presenting the arguments that are important to your boss!

In this blog, I look at how you can talk to your boss to convince them to get you that new, shiny calibrator. Let's dive in and unlock the secrets to getting that "yes!"

First, let’s look at the needs of calibration technicians. Then, I list some of the things that typically matter to bosses and managers - the decision makers. Finally, I’ll discuss how you should present your arguments to your boss to get approval for buying your new calibrator.

What matters to calibration technicians

Let’s briefly look at the things that normally matter the most to the people who are using the calibrators. Often, they are calibration technicians, or calibration engineers.

- Less to carry – The calibrator should be multifunctional, so that you don’t need to carry several separate tools with you out in the field.

- Easy to use – You need to do many different jobs and use many different systems and tools, so the calibrator should be easy to learn and to use. You don’t necessarily use the calibrator every day, so it must be easy to use.

- Accurate - Good accuracy is naturally a must-have. You can’t calibrate and adjust field instruments properly if your calibrator is not accurate enough. Field instruments are improving and getting more accurate, so should your calibrators.

- Automation – If your calibration tools can automate part of your work, that is a great time saver.

- Automatic documentation – Since you need to document the calibration you do, it is great if the calibrator can do the documentation automatically so you don’t need to play with pen and paper.

What matters to the bosses/managers

Of course, the priorities and well-being of calibration technicians are important to any manager. But still, the things that matter most to managers are usually different to what matter to technicians.

Typically, the following things are important to managers:

- Costs and ROI – Making sure that the operational costs do not exceed budgets. And that any new investments provide a good return on investment (ROI).

- Productivity and efficiency – Doing more with less. There seem to be fewer resources everywhere, but you still need to get more and more done.

- Digitalization – It is very difficult to find a plant these days that doesn’t have digitalization initiatives ongoing.

- Reliability and downtime reduction – Making sure that processes run reliably, and any downtime is minimal.

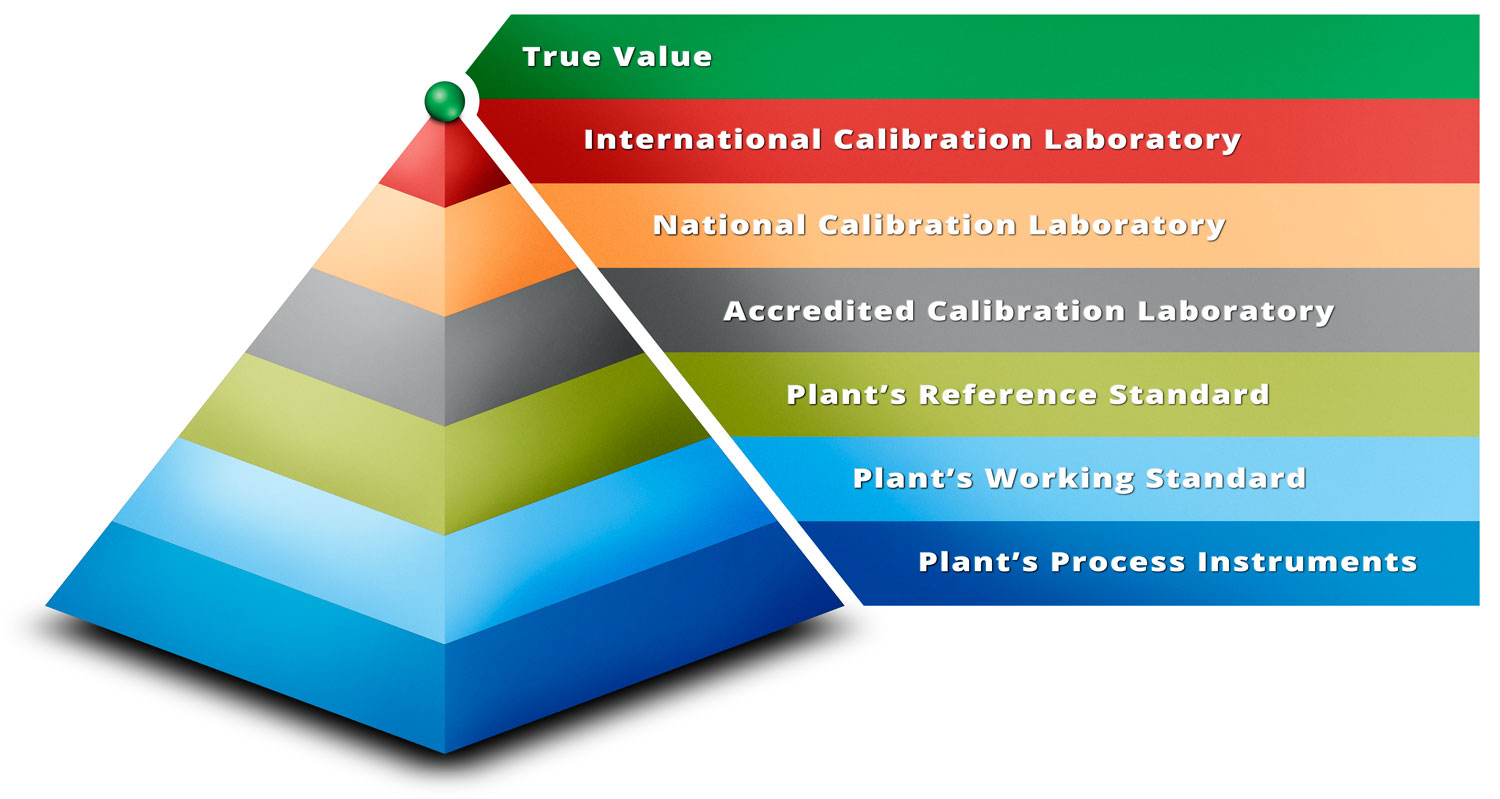

- Regulatory compliance – It’s important to ensure that processes are compliant with all relevant standards and regulations.

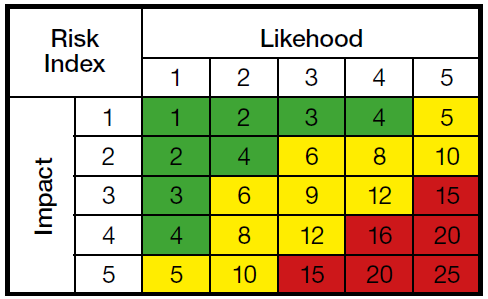

- Safety and risk management – The safety of workers (and customers) and risk management are important.

- Training and skills development – Employees need to be trained to make sure their skills stay up to date.

- Data quality and integrity – The quality and integrity of calibration data needs to be ensured.

- Sustainability and environment – Environmental considerations such as waste and energy reduction and effluent monitoring need to be taken into account in operations.

How to convince your boss

As you saw, there are some differences between the things that matter to technicians and the things that matter to bosses. So how do you discuss with your boss to get the approval to buy your new calibrator?

Obviously, you still have the reasons that matter most to you, but you need to focus on the things that are important to your boss.

Your discussion topics could include following:

- Productivity and efficiency – Highlight that the automated features of the new calibrators make you and your team more productive and efficient, so you get your job done faster and better.

- Data quality and integrity – Using modern documenting calibrators will automate documentation, not only making your job more efficient, but also improving the quality of data. This is because it reduces the human errors always present in manual documentation.

- Costs and ROI – Although new calibrators will always come with a price tag, improved efficiency ensures a good ROI and short pay-back time.

- Digitalization – New modern documenting calibrators will take the first important steps towards digitalization of your calibration processes. Every boss love digitalization! In future, you can combine those documenting calibrators with calibration management software, and you have digitalized your calibration ecosystem and turn it paperless! Down the road, your calibration software can be connected to your CMMS system to digitalize and automate also your work order delivery.

- Regulatory compliance – A digitalized calibration ecosystem makes it easier to comply with quality standards and regulations. It also makes any audits so much easier.

- Training and skills development – New calibrators with a modern user interface are easier to use and easier for new workers to learn.

- Safety and risk management – In case you need to work in hazardous areas, having intrinsically safe calibrators will make it so much safer to work. It also makes it more efficient as you don’t need to work with hot work permits and carry gas detectors like you do with regular calibrators.

Summary

So, there you have it! Getting your boss to buy a new calibrator isn't about listing all the cool features you want. It's about understanding what matters to them and framing your arguments in a way that speaks to their priorities. By focusing on the right things, you'll make a strong case for why this investment makes sense for the whole team. Use these tips, you’ll be able to speak your boss's language, bringing you one step closer to working with that shiny (hopefully green) new calibrator. Good luck! Please let me know how it goes!

If you are ready for some commercial content, please read on.

Discover your potential savings!

Convincing your boss to invest in a new calibrator is easier when you can demonstrate significant time and cost savings. Use our Calibration Savings Calculator to see how much your organization can save. By inputting a few details about your current calibration processes, you can uncover the potential financial benefits and efficiency improvements.

Start calculating your savings now and make a compelling case for your new calibrator!

Access Calibration Process Savings Calculator >>

Look no further for the new calibrator!

So where do you find that dream calibrator that fulfills all the arguments listed above?

Well, I’m glad you asked! :-)

Check out the Beamex MC6 family of calibrators – a series of advanced, truly multifunctional calibrators designed to digitalize and revolutionize your calibration work!

The Beamex MC6 family includes:

- MC6 Advanced Field Calibrator and Communicator: The all-in-one solution for versatile field calibration. It combines advanced process calibration functionality with a built-in communicator, making it ideal for on-the-go calibration tasks. Its high accuracy and robust design ensure reliable performance in various field conditions.

- MC6-Ex Intrinsically Safe Advanced Field Calibrator and Communicator: Safe and reliable for hazardous areas. Designed to meet stringent safety standards, it ensures precise calibration in potentially explosive environments. The MC6-Ex is indispensable for industries requiring strict safety protocols.

- MC6-T Multifunction Temperature Calibrator and Communicator: Specialized in precise temperature calibration. It offers unique features for accurate automated temperature measurements, making it indispensable for temperature-critical applications. Its multifunctionality and ease of use make it a valuable tool for any calibration task.

- MC6-WS Workshop Calibrator and Communicator: Optimized for comprehensive workshop calibration. It provides extensive calibration capabilities in a stationary setup, making it perfect for detailed and routine calibration tasks in the workshop. Its high accuracy and automated features enhance efficiency and reliability.

Common key features and benefits of the MC6 family

- Multifunctionality: Calibrate pressure, temperature, electrical signals, and more.

- Your benefit: Reduces the need for multiple devices, simplifying your toolkit and saving space. Carry less!

- High accuracy: Ensure precise calibration with industry-leading performance.

- Your benefit: Achieves reliable and consistent results, meeting rigorous industrial standards.

- User-friendly interface: Navigate effortlessly with an intuitive touchscreen.

- Your benefit: Saves time and reduces training requirements, making it easier for technicians to operate.

- Documentation: Automatically document your calibrations.

- Your benefit: Streamlines compliance and reporting processes, reducing manual data entry and potential errors.

- Durable design: Built to withstand demanding environments.

- Your benefit: Increases longevity and reliability, providing a robust solution for field and workshop use.

Calibration Management Software

Combine an MC6 family calibrator with our calibration management software for a fully digitalized and paperless calibration ecosystem.

- Beamex CMX Calibration Management Software: Efficiently manage your calibration data, automate processes, and generate reports with ease.

- Beamex LOGiCAL Calibration Management Software: Cloud-based calibration software for easy access and management of your calibration data anytime, anywhere.

Ready to take the next step?

Ready to take the next step and upgrade your calibration process? Here are some ways to get started:

- Book a meeting: Schedule a meeting with our experts to discuss your specific calibration needs and find the best solutions.

- Request a demo: Experience the MC6 family in action by requesting a live or online demo.

- Contact us: Reach out to our team for any inquiries or to get a personalized quote.

.jpg)

.png)

Discussion