A Tale of Three Steves

Stephen Jerge, Calibration Supervisor for Lonza Biologics, a multinational chemical and biotechnology company, recently walked attendees of the Beamex Annual Calibration Exchange (ACE) through the project he headed to transition from a paper-based calibration management system (CMS) to an integrated, digital, paperless solution using Beamex CMX. Steve has over 30 years of calibration experience in the telecommunication and pharmaceutical industries.

Over the last 3 years, his primary focus has been contributing to Lonza’s global paperless SAP/CMX integrated solution through implementation, training, and supporting calibration operations and expansion projects.

Watch the presentation video recording now!

In this blog post, we’ll share The Tale of Three Steve’s as we follow his journey from 2017 Steve, a stressed-out, overworked supervisor; to 2019 Steve as he underwent the rollout of a new, automated system; to Steve 2021, whose focus is on continuous improvement.

2017 Steve - Managing a paper-based process

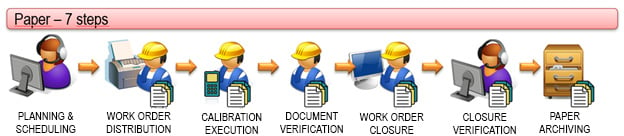

Steve starts by bringing us back to 2017 when the calibration process was paper-based and manual. “It couldn’t be more inefficient,” notes Steve. “Everything from standards selection, approvals, and calculations were done manually. All historical data was "safely locked up in a filing cabinet" and not doing any good at all.”

Below – is a visual representation of the paper-based process. As Steve notes, “Each arrow in this image is time and money and each person is an error trap.”

Does any of this sound and look familiar to you? Keep reading to find out how Steve got out of this heavily manual and error-prone process.

Clearly, something needed to change. Steve and the management team at Lonza outlined their main priorities: Quality, Consistency, Efficiency, and Cost.

Quality

As a pharmaceutical manufacturer, quality is their first priority. With the existing methods, they were doing at about 20% technical review, as a quality component, and everything else was getting a GMP (Good Manufacturing Practice) review at an administrative level. They wanted to leverage a CMS system so they could have a 100% review done as the work was completed, as opposed to days or weeks later when the manual review was performed. They wanted to be able to reduce human errors before they happened.

Consistency

With a paper system, it’s easy to make mistakes such as calculation errors.

Efficiency

If we look at the image above outlining the paper-based steps, automation doesn’t remove the arrows, but it makes them easier, more streamlined, and ultimately takes them out of the hands of the technicians. This allows technicians more time to focus on their roles.

As Steve states, “If you’re running a NASCAR race and the technician must get out of the car, change the tires, clean the windshield and add the fuel, you’re going to come in last place every time.” An automated process gives the technician the time and resources to do the work that needs to be done.

Likewise, an automated process means you’re able to take the knowledge a tenured technician has gathered over the years and include it as part of the process. This way, the next person that must do the work, be they a contractor or new technician, has all the information needed to be successful.

Managing by exception* – the CMX process reviews the work order and flags any issues that need review.

*Learn more about this by listening to the roundtable discussion from day one of the Annual Calibration Exchange.

Cost

Clearly, this is a huge issue. Rework means they need to reclean, reschedule, stop production, etc. All of these cost money. By leveraging the CMX technology, they make rework less necessary and have improved processes.

2019 Steve – Implementing automation

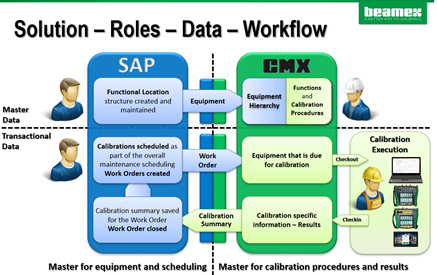

After outlining all their priorities and deciding to implement Beamex CMX as their CMS of choice, Lonza was ready to go from a paper-based process to a fully integrated SAP Computer Maintenance Management System (CMMS) process.

The first benefit of the new system is the new automated review process. Because CMX includes 7 built-in checks, only those items with red flags need to be reviewed. Technicians can also flag work orders for a second review if any questions arise during the calibration process. All other work orders can be closed in as little as one hour.

In 2019, Lonza also moved to use the Beamex MC6 as their primary calibrator. The MC6 replaced 5 or more types of standards. Because the MC6 meets all the functions for each standard, the technicians can now use the technology to be more efficient.

Prior to automating the process, Lonza was having issues keeping up with items that were nearing being past due for calibration. By leveraging the integration between CMX and SAP, the Calibration Team at Lonza was able to make huge improvements in scheduling and tracking. Utilizing SAP also allows them to manage external vendor orders. Now, internal and external items can be efficiently tracked.

Let’s look at how the SAP to CMX integration works:

In short, SAP cares about the when, where, and who of the process. CMX cares about HOW. CMX provides preselected calibration standards with standard warnings, test point warnings, passed/failed/adjust warnings, etc. CMX can also perform calculations and conduct an automated review.

2021 Steve – Continuous improvement

With the integrated process fully implemented, Steve can now focus on ways to continue to make life easier for the technicians. They have added pre-work instructions for each work order. This allows them to take the knowledge from the seasoned technician and load that information into CMX. Now, the location, special tools/fittings information, post-work instructions, etc. are readily available.

Checklist/inspection functions were also added. These include a combination of simple instructions, plus critical tasks that may not be calibration-related but are essential to the function of the equipment. This reinforces procedure, is paperless, provides another level of quality, and reduces time on deviation.

From a technician’s perspective, life is pretty straightforward now. You check out the calibration, execute the calibration (following along with all the defined steps), then check-in and close. Technicians can provide feedback through the second approval process or by adding notes in CMX. This information is brought to management for review and can be triaged based on how critical the notes are.

Final Words

Steve summarizes his journey by saying, "When you implement a major change – and take people out of their comfort zone – it can turn lives upside down. Management needs to support their technicians and their team through these changes. If they can do this successfully, the technician’s job will be easier in the long run and supervisors will have the ability to manage by exception, focus on continuous improvement, and work with a happier and more productive team."

To learn more about how Steve has moved to managing by exception with CMX, take a look at the round table discussion from ACE 2021.

Check out Steve Jerge's video presentation, plus other insights from industry experts, on the Beamex 2021 Annual Calibration Exchange Video Library.

Want more information on CMMS and Calibration System Integrations?

Check out these blog posts:

.png)

.jpg)

.png)

Discussion