In this blog post we want to share with you an educational eBook focusing on temperature calibration and other temperature related topics.

Some of these articles have been already earlier posted in Beamex blog, but now several temperature related resources have been collected into one free handy eBook.

Contents of the eBook

The eBook contains following articles:

- Uncertainty components of a temperature calibration using a dry block (Page 4)

- Pt100 temperature sensor — useful things to know (Page 13)

- Thermocouple Cold (Reference) Junction Compensation (Page 21)

- Temperature units and temperature unit conversion (Page 27)

- How to calibrate temperature sensors (Page 31)

- AMS2750E heat treatment standard and calibration (Page 37)

- Optimal testing parameters for process instrument calibration (Page 45)

Abstracts of the articles

Here are short abstracts of each article included in the eBook:

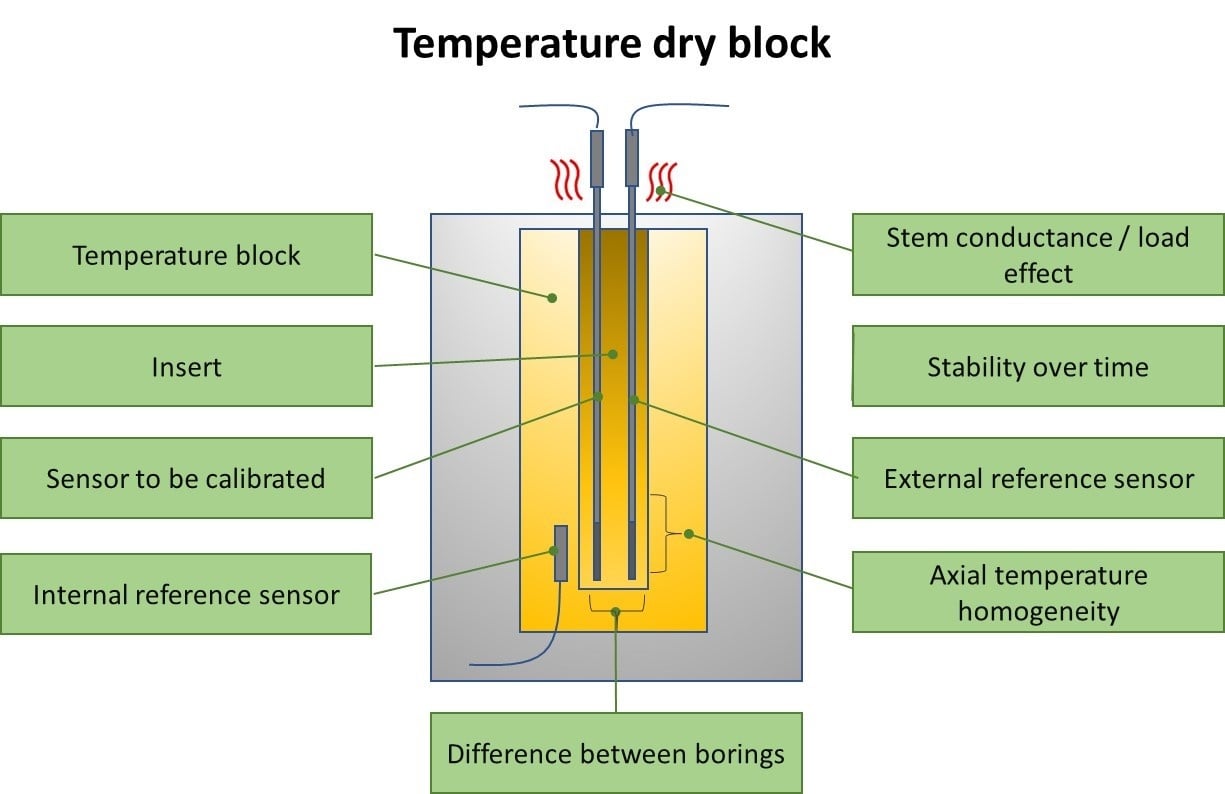

Uncertainty components of a temperature calibration using a dry block

In this article, we will be covering the different uncertainty components that you should consider when you make a temperature calibration using a temperature dry block.

In this article, we will be covering the different uncertainty components that you should consider when you make a temperature calibration using a temperature dry block.

Making a temperature calibration using a dry block seems like a pretty simple and straight forward thing to do, however there are many possible sources for uncertainty and error that should be considered.

Often the biggest uncertainties may come from the procedure on how the calibration is done, not necessarily from the specifications of the components.

Pt100 temperature sensor — useful things to know

Pt100 temperature sensors are very common sensors in the process industry. This article discusses many useful and practical things to know about the Pt100 sensors. There’s information on RTD and PRT sensors, different Pt100 mechanical structures, temperature-resistance relationship, temperature coefficients, accuracy classes and on many more.

Pt100 temperature sensors are very common sensors in the process industry. This article discusses many useful and practical things to know about the Pt100 sensors. There’s information on RTD and PRT sensors, different Pt100 mechanical structures, temperature-resistance relationship, temperature coefficients, accuracy classes and on many more.

Thermocouple Cold (Reference) Junction Compensation

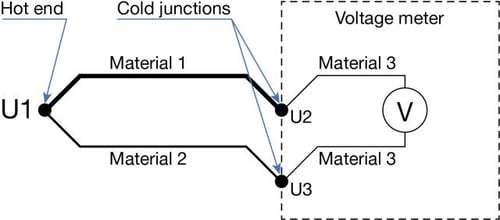

Even people who work a lot with thermocouples don’t always realize how the thermocouples, and especially the cold (reference) junction, works and therefore they can make errors in measurement and calibration.

Even people who work a lot with thermocouples don’t always realize how the thermocouples, and especially the cold (reference) junction, works and therefore they can make errors in measurement and calibration.

In this article, we will take a short look at the thermocouple cold junction and the cold junction compensation. To be able to discuss the cold junction, we need to take first a short look into the thermocouple theory and how a thermocouple works.

We won’t go very deep in the theoretical science but will stick more with practical considerations, the kind of things you should know when you work with thermocouple measurements and calibrations in a typical process plant.

Temperature units and temperature unit conversion

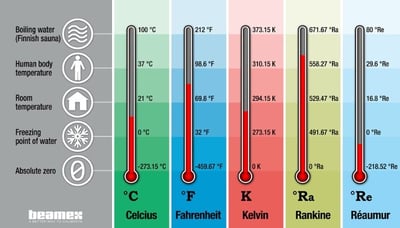

This article discusses temperature, temperature scales, temperature units and temperature unit conversions. Let’s first take a short look at what temperature really is, then look at some of the most common temperature units and finally the conversions between them.

This article discusses temperature, temperature scales, temperature units and temperature unit conversions. Let’s first take a short look at what temperature really is, then look at some of the most common temperature units and finally the conversions between them.

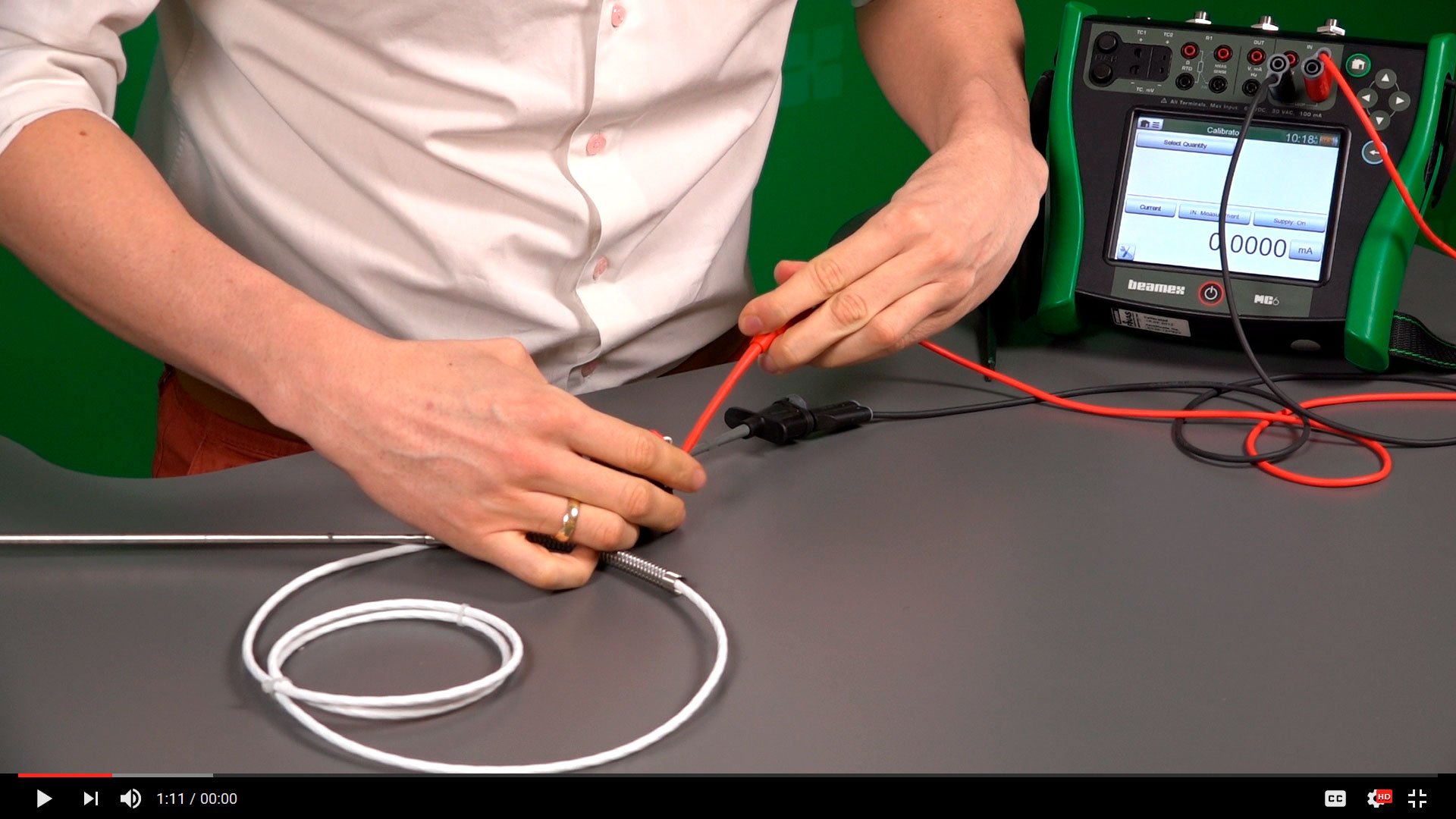

How to calibrate temperature sensors

Every temperature measurement loop has a temperature sensor as the first component in the loop. So, it all starts with a temperature sensor. The temperature sensor plays a vital role in the accuracy of the whole temperature measurement loop.

Every temperature measurement loop has a temperature sensor as the first component in the loop. So, it all starts with a temperature sensor. The temperature sensor plays a vital role in the accuracy of the whole temperature measurement loop.

As any measurement instrument you want to be accurate, also the temperature sensor needs to be calibrated regularly. Why would you measure temperature, if you don’t care about the accuracy?

In this article, we will take a look at how to calibrate temperature sensors and what are the most common things you should consider when calibrating temperature sensors.

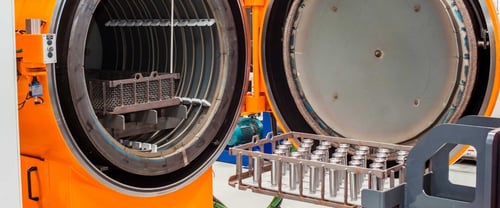

AMS2750E heat treatment standard and calibration

In this article, we will take a look at the AMS2750E standard, with a special focus on the requirements set for accuracy, calibration and test/calibration equipment.

In this article, we will take a look at the AMS2750E standard, with a special focus on the requirements set for accuracy, calibration and test/calibration equipment.

The AMS2750E is predominantly designed for heat treatment in the aerospace industries. Heat treatment is an essential process for many critical parts of an airplane, so it is understandable that there are tight regulations and audit processes set.

While the results and success of some other industrial processes can be relatively easily measured after the process, this is not the case in a heat treatment process. Therefore, very tight control and documentation of the heat treatment process is essential to assure the quality of the end products.

Optimal testing parameters for process instrument calibration

Most calibration technicians follow long-established procedures at their facility that have not evolved with instrumentation technology. Years ago, maintaining a performance specification of ±1% of span was difficult, but today’s instrumentation can easily exceed that level on an annual basis. In some instances, technicians are using old test equipment that does not meet new technology specifications.

Most calibration technicians follow long-established procedures at their facility that have not evolved with instrumentation technology. Years ago, maintaining a performance specification of ±1% of span was difficult, but today’s instrumentation can easily exceed that level on an annual basis. In some instances, technicians are using old test equipment that does not meet new technology specifications.

This paper focuses on establishing base line performance testing where analysis of testing parameters (mainly tolerances, intervals and test point schemes) can be analyzed and adjusted to meet optimal performance. Risk considerations will also be discussed—regulatory, safety, quality, efficiency, downtime and other critical parameters.

A good understanding of these variables will help in making the best decisions on how to calibrate plant process instrumentation and how to improve outdated practices.

New temperature calibrator Beamex MC6-T

If you work with temperature calibration, please check out our latest temperature calibrator Beamex MC6-T.

Click the below picture to learn more:

Links to the individual blog articles

Here are links to the individual blog articles:

- Uncertainty components of a temperature calibration using a dry block

- Pt100 temperature sensor – useful things to know

- Thermocouple Cold (Reference) Junction Compensation

- Temperature units and temperature unit conversion

- How to calibrate temperature sensors

- AMS2750E Heat Treatment Standard and Calibration

- Optimal Calibration Parameters for Process Instrumentation

.jpg)

.png)

Discussion