Update (2025):

This article was originally written when AMS2750 revision E was current. The standard has since advanced through revisions F, G, and H, adding clearer pyrometry definitions, tighter thermocouple and calibration practice requirements, and more emphasis on digital instrumentation and electronic records. Importantly, the core accuracy requirements for calibration instruments have remained essentially the same, so the calibrator accuracy principles and graphics discussed here are still valid. In practice, most updates affect procedures, sensors, and documentation rather than the accuracy level you need from your calibrator. As always, review the latest AMS2750 revision for detailed compliance requirements.

In this blog post, I will take a short look

The AMS2750E is predominantly designed for heat treatment in the aerospace industries. Heat treatment is an essential process for many critical parts of an airplane, so it is understandable that there are tight regulations and audit processes set.

While the results and success of some other industrial processes can be relatively easily measured after the process, this is not the case in a heat treatment process. Therefore, very tight control and documentation of the heat treatment process is essential to assure the quality of the end products.

AMS2750 standard

As mentioned, the AMS2750E is a standard for the heat treatment. The “AMS” name in the standard is an abbreviation of “Aerospace Materials Specifications”. The standard is published by SAE Aerospace, part of SAE International Group. The first version of the AMS2750 standard was published in 1980. Followed by revisions: revision A in 1987, B also in 1987, C in 1990 and D in 2005. The current revision AMS2750E was published in 2012.

The AMS2750 standard was initially developed to provide consistent specifications for heat treatment through the aerospace supply chain. The use of the standard is audited by PRI (Performance Review Institute) for the Nadcap (National Aerospace and Defense Contractors Accreditation Program). Prior to Nadcap, aerospace companies each audited their own suppliers, so there was a lot of redundancy and duplication of efforts. In 1990, the PRI was established to administer the Nadcap program.

AMS2750E scope

According to the standard itself, the scope of the AMS2750E standard is the following:

"This specification covers pyrometric (high temperature) requirements for thermal processing equipment used for heat treatment. It covers temperature sensors, instrumentation, thermal processing equipment, system accuracy tests, and temperature uniformity surveys. These are necessary to ensure that parts or raw materials are heat treated in accordance with the applicable specification(s)."

Why for heat treatment?

In some industrial processes, it is relatively easy to measure and check the quality of the final product and judge if the product fulfills the requirements after the process is complete. You may be able to simply measure the end product and see if it is good or not.

In other processes where it is not possible/easy/practical to measure the quality of the final product you need to have a very tight control and documentation of the process conditions, in order to be sure that the final product is made according to the requirements.

It is easy to understand that heat treatment is a process where you need to have a very good control of the process in order to assure that you get the required end product, especially since the products are mostly used by the aerospace industry.

Who is it for?

The AMS2750E is predominantly designed for the aerospace industries. But the same standards and processing techniques can be used within any industry which requires control of the thermal processing of raw materials and manufactured components, such as automotive, rail and manufacturing.

But what is the CQI-9?

The CQI-9 is a similar set of requirements for heat treatment, mainly aimed

Test instruments and calibration

Let’s discuss Test Instruments (calibrators) and what AMS2750E says about them.

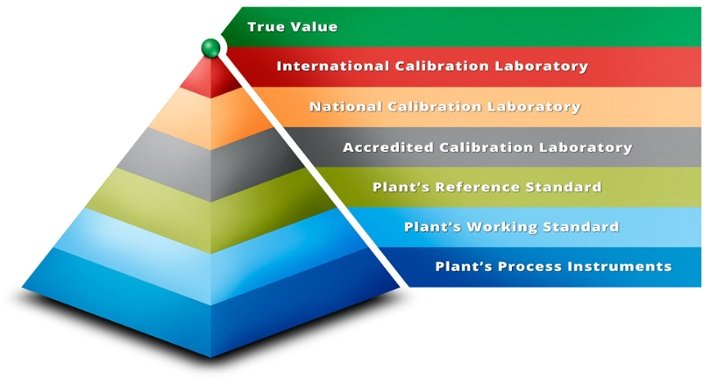

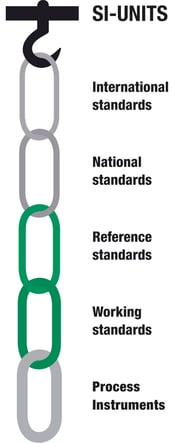

A traceable calibration of different levels of measurement instruments is obviously required. The higher level standards are typically calibrated in an external calibration laboratory. The process measurements are calibrated internally using “field test instruments”.

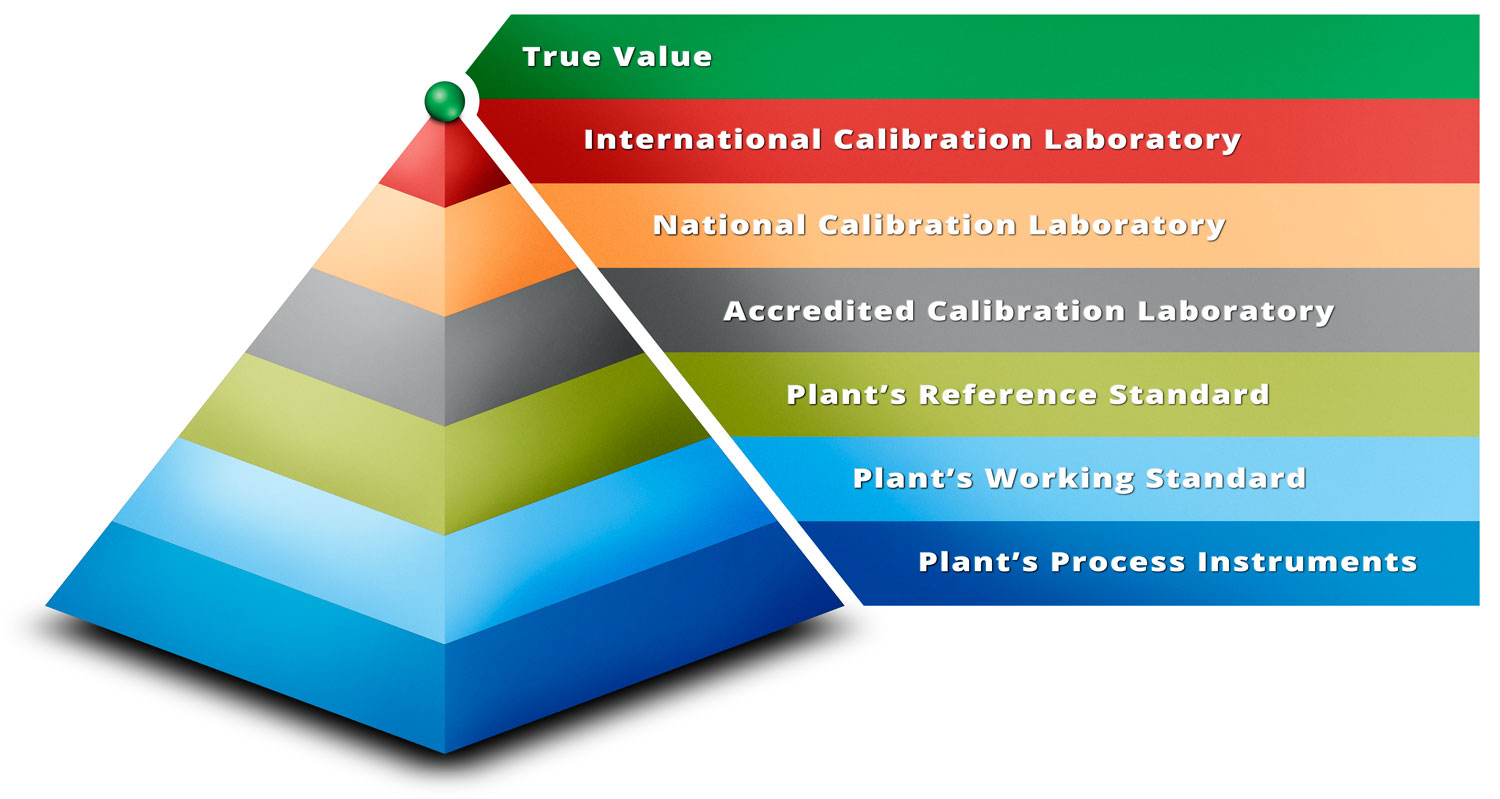

Metrological Traceability is often described as traceability pyramid, or as a traceability chain, see below:

Traceability pyramid:

Traceability chain:

To learn more about the metrological traceability in calibration read the following blog post:

Metrological Traceability in Calibration – Are you traceable?

The magical "Table 3"

In the Table 3 in the AMS2750E standard, there are different specifications for the test standards and test equipment/calibrators. The different levels of instruments are classified as follows:

- Reference standard

- Primary standard

- Secondary standard instruments

- Secondary standard cell

- Field test instrument

- Controlling, monitoring or recording instruments

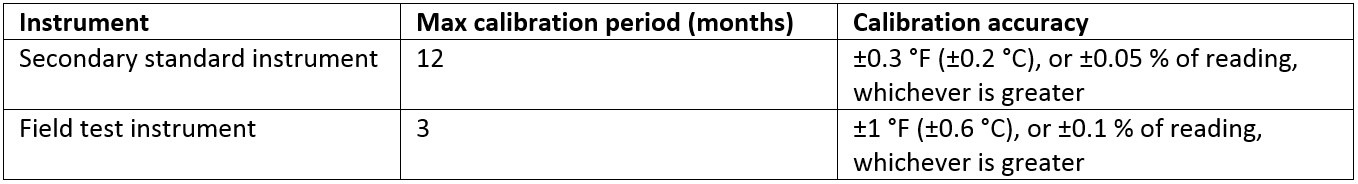

For each instrument class, there are specifications for the calibration period and calibration accuracy. If we think about calibrators/calibration equipment, it is typically used as “field test instrument” or sometimes as “secondary standard instrument” and following are said about those:

Secondary standard instrument

- Limited to laboratory calibration of field test instruments, system accuracy test sensors, temperature uniformity survey sensors, load sensors and controlling, monitoring or recording sensors

Field test instrument

- Calibration of controlling, monitoring, or recording instrument,

performance of system accuracy tests, and temperature uniformity surveys

AMS2750E accuracy requirements

AMS2750E also specifies the calibration period and accuracy requirements for the different levels of instruments, below is what is said about the secondary standard instrument and field test instrument:

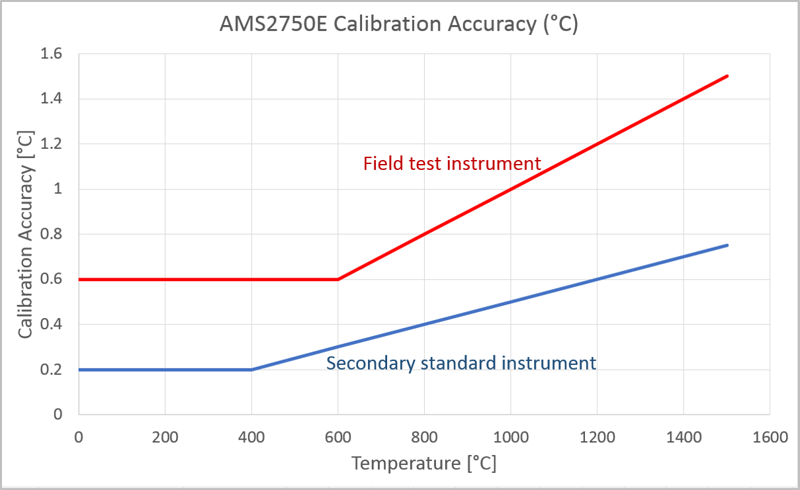

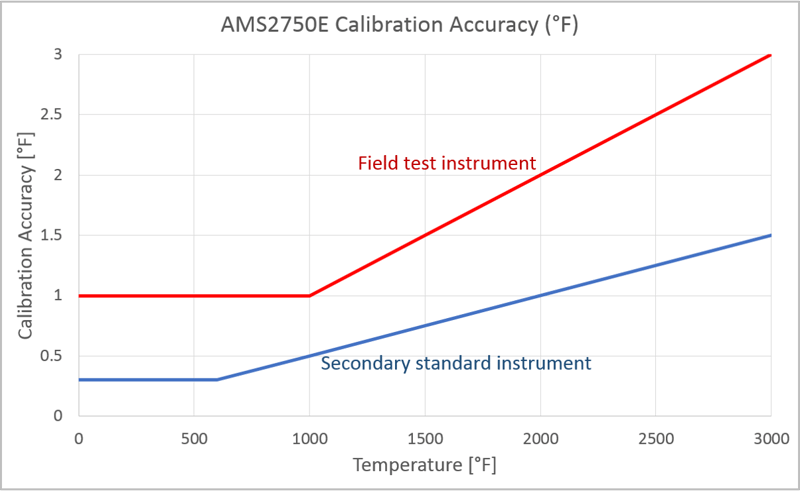

Sometimes it is easier to look at a visual, so let's look at this required calibration accuracy graphically for “field test instrument” and “secondary standard instrument”. And as the Centigrade and Fahrenheit are different, below is a graph of both for your convenience:

Contradiction with different thermocouples types and accuracy

The AMS2750E standard specifies different thermocouple types for different usage. Types B, R

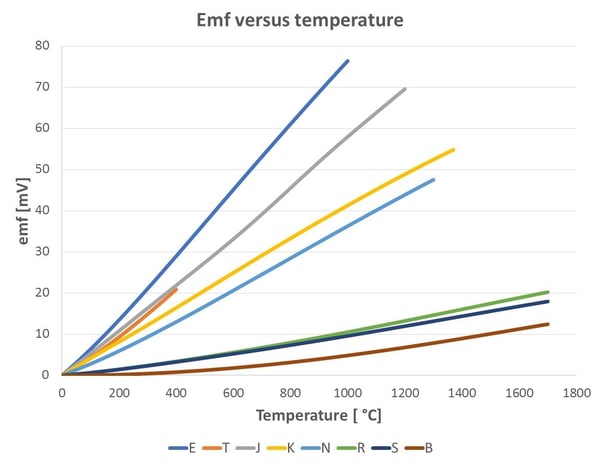

Anyhow, the standard has the same accuracy specification regardless of the thermocouple type. This is a slightly strange requirement, as different thermocouples have much different sensitivities.

In practice, this means that a test field instrument (calibrator) normally has a specification for millivoltage, and when this mV accuracy is converted to temperature it means that the calibrator normally has different specifications for different thermocouple types. Some thermocouple types have

For example - a calibrator can have an electrical specification of 4 microvolts at 0 V. With a K type, this 4 µV equals a temperature of 0.1 °C (0.2 °F), but for a S type, this equals 0.7°C (1.3°F), and for a B type it equals almost 2°C (3.6 °F). Therefore, calibrators normally have very different accuracy specifications for different thermocouple types.

So the standard having the same accuracy regardless of the thermocouple type is a bit strange requirement.

To illustrate the different sensitivities of different thermocouple types, please see the graphics below. The graph shows what kind of thermovoltage (Emf) is generated in different temperature by different thermocouple types:

To learn more about thermocouples, different thermocouple types and thermocouple cold junction compensation, please read this blog post:

Thermocouple Cold (Reference) Junction Compensation

AMS2750E contents in a nutshell

Let’s take a brief look at the contents of the AMS2750E standard and further discuss a few key points in the standard.

The AMS2750E standard starts with sections:

- 1. Scope

- 2. Applicable documents

Chapter 3 “Technical Requirements” of AMS2570E includes the following key sections. (These sections are discussed in more details in the next chapters):

- 3.1 Temperature sensors

- 3.2. Instrumentation

- 3.3. Thermal processing equipment

- 3.4. System Accuracy Tests (SAT)

- 3.5. Furnace Temperature Uniformity Survey (TUS)

- 3.6. Laboratory furnaces

- 3.7. Records

- 3.8. Rounding

The remaining sections are:

- 4. Quality assurance provisions

- 5. Preparation for delivery

- 6. Acknowledgement

- 7. Rejections

- 8. Notes

3.1 Temperature sensors

Section 3.1 discusses temperature sensors. Some key bullets from that section:

- The AMS2750E standard specifies the thermocouple sensors to be used, as well as the sensor wire types.

- The voltage to temperature conversion standard to be used (ASTM E 230 or other national standards).

- Correction factors may be used to compensate for the errors found in calibration.

- The temperature range for the sensors used.

- Allowance to use wireless transmitters.

- Contents of a sensor calibration certificate.

- The max length of sensor wire/cable.

- The max number of usage of thermocouples in different temperatures.

- Types of thermocouple sensors to be used, the use for thermocouples (primary calibration, secondary calibration, sensor calibration, TUS, SAT, installation, load sensing), calibration period for thermocouples, and maximum permitted error.

3.2 Instrumentation

Section 3.2 covers the instrumentation that the sensors are used with. This includes control, monitoring, recording, calibration, instrumentation, etc.

- Instruments need to be traceably calibrated.

- Minimum resolution/readability of test instruments (1 °F or 1 °C).

- Specifications for electronic records.

- Contents of calibration sticker:

- Date, due date, performed by, any limitations

- Contents of calibration record:

- Instrument identification, make and model, standard(s) used, calibration method, required accuracy, as found and as left data of each calibration point, offset, found/left, sensitivity, statement of acceptance or rejection, any limitations or restrictions, calibration date, due date, performed by, calibration company, signature, quality, organization approval.

3.3 Thermal processing equipment

Section 3.3 discusses the furnace classification and the temperature uniformity requirements in each class. Going from class 1 having uniformity requirement of ±5°F / ±3 °C, to class 6 with ±50 °F / ±28 °C.

3.4 System accuracy test (SAT)

Section 3.4 discusses the system accuracy tests (SAT). The SAT is an on-site test where the whole measurement loop (

SAT shall be performed with a “field test instrument,” specified in the standard’s Table 3. SAT should be performed periodically or after any maintenance. SAT interval is based on equipment class and instrumentation type.

SAT test records shall include:

- identification of sensor calibrated

- ID of reference sensor

- ID of test instrument

- date and time

- set points

- readings of furnace under test

- test instrument readings

- test sensor correction factors

- corrected test instrument reading

- calculated system accuracy difference

- an indication of acceptance or failure

- who performed the test

- signature

- quality organization approval

3.5 Temperature uniformity surveys (TUS)

Section 3.5 is about furnace temperature uniformity survey (TUS). The

There are many detailed specifications for

The TUS report shall include:

- furnace identification

- survey temperatures

- sensor location and identification including detailed diagrams

- time and temperature data from all sensors

- correction factors for sensors in each temperature

- as found and as left offsets

- corrected/uncorrected readings of all TUS sensors at each temperature

- testing company identification and signature

- identification of the person who performed the survey

- survey start date and time

- survey end date and time

- test instrumentation identification

- identification of pass or fail

- documentation of sensor failures (when applicable)

- summary of corrected plus and minus TUS readings at each temperature after stabilization

- quality organization approval

Q&A session with Deutsche Edelstahlwerke

We had a Questions & Answers session with Mr. Julian Disse (Team Coordinator Quality Assurance Special Standards) at Deutsche Edelstahlwerke and discussed on the challenges on following the AMS2750 standard, audits, measurements, calibrations, sensors, traceability and other things.

Please download the adjacent white paper to read the discussion.

An example customer case story

Here's an example case story of company Trescal, UK. They are a calibration service provider for aerospace customers and need to follow the AMS2750 standard. Trescal have found Beamex calibrators (MC2, MC5

Case story: Trescal, UK - Extreme accuracy calibrations for aerospace giant

Summary

The AMS2750E specifications set a high standard for the aerospace industry. After reviewing sensor technology and the challenges for test equipment to make proper measurements, meeting accuracy requirements takes careful analysis and continuous supervision. It should be noted that the AMS2750E specifications are not easily met and accurate test equipment must be utilized. By addressing calibration requirements up front, maintenance personnel will be equipped with the proper tools and procedures to not only maintain compliance but ensure the best product quality. Good sensor measurements set the stage for good process control with repeatable results – a good formula for staying in business.

Download the free white paper

You can download the free pdf white paper by clicking the picture below:

Beamex solutions for AMS2750E

Beamex offers various temperature calibration products that can be used (and are being used) in an AMS2750E environment. You can find the detailed information of our offering on our website in the below link:

Beamex temperature calibration products

Please contact us for information on how our products can be used in an AMS2750 environment.

Related blog posts

If you found this article interesting, you might also like these blog posts:

- Pt100 temperature sensor – useful things to know

- Thermocouple Cold (Reference) Junction Compensation

- Temperature units and temperature unit conversion

- Metrological Traceability in Calibration – Are you traceable?

Please subscribe

If you like these blog articles, please subscribe to this blog by entering your email address to the "Subscribe" box on the upper right-hand side. You will be notified by email when new articles are available, normally about once in month.

Also, feel free to suggest topics for new articles!

.png)

.jpg)

Discussion