So you have invested in some new, accurate calibration equipment. Great!

But as with many other things in life, also accuracy fades over time.

To ensure that your calibration equipment serves you well and stays accurate throughout its lifetime, it needs to be recalibrated periodically. It also needs to be serviced and adjusted whenever necessary.

When choosing a calibration laboratory or calibration service, you need to select one that is capable of calibrating your accurate equipment with sufficient uncertainty.

We have seen the accuracy of a calibrators being destroyed in a non-competent laboratory. I want to help you to avoid that.

What do you need to consider when choosing a calibration laboratory?

In this blog post I will discuss the most important things to consider when choosing a calibration laboratory for your precious calibrator or reference standard.

Table of Content

How to choose a calibration laboratory - 13 things to consider

- Manufacturer’s laboratory

- Laboratory accreditation

- Calibration uncertainty

- Calibration certificate

- Pass/Fail judgment

- Adjustment

- As Found / As Left calibration

- Turnaround time

- Brand and reputation

- Price

- Repairs, service, and maintenance

- Warranty

- Agreements and reminders

What do we do at the Beamex calibration laboratory?

Download this article as a free pdf file by clicking the picture below:

Background

To match the ever-improving accuracy race of process instrumentation, also the calibration equipment is getting more and more accurate. This puts more pressure on the accuracy of the calibration laboratories, and they also need to improve their accuracy to match these requirements with sufficient accuracy ratio.

Many modern process calibrators are multifunctional, containing several quantities and multiple ranges. This is great for users as they only need to carry one multifunctional calibrator with them in the field.

But multifunctionality makes recalibration more challenging for the calibration laboratory. Not all laboratories can calibrate multiple quantities and ranges with sufficient accuracy and uncertainty.

Even if you choose an accredited calibration laboratory it will not always offer the required uncertainty for all the ranges.

Something that we sometimes see in our calibration laboratories at the Beamex factory is that customers have bought the most accurate and multifunctional calibrator we offer (for example, the Beamex MC6) and it has been calibrated in a local calibration laboratory. The MC6 calibrator is packed with several accurate pressure, electrical, and temperature ranges, so is not the easiest to recalibrate. In some cases, the laboratories have claimed that the calibrator does not fulfill its accuracy/uncertainty specifications, but when the case is investigated it is commonly found that the laboratory’s uncertainty is worse than the calibrator’s uncertainty!

And even worse, we have also seen local labs adjusting the calibrators with the intention of making them ‘more accurate’. Next time our calibration laboratory calibrates the calibrator, it is discovered that the unit was adjusted incorrectly and it is out of specifications! In some cases the customer has been already using an out-of-spec calibrator for some time, which can have serious consequences.

I therefore wanted to discuss the topic of choosing a suitable calibration laboratory in this article.

How to choose a calibration laboratory - 13 things to consider

1. Manufacturer’s laboratory

One good way to choose a calibration laboratory is to use the equipment manufacturer’s laboratory, if that is practical. The manufacturer knows anyhow all the ins and outs of the equipment and has the capability to calibrate it. The manufacturer can also do any service or maintenance work that may be required. Also, using the manufacturer’s calibration service does not jeopardize the warranty of the equipment; they may even offer an extended warranty.

It is however not always possible or practical to use the manufacturer’s calibration laboratory, so let’s discuss some other considerations.

2. Laboratory accreditation

Choosing a calibration laboratory or service that has accreditation is the most important thing to start with, especially if it is not possible to use the manufacturer’s calibration laboratory.

Calibration laboratory accreditation is done by a formal third-party authority to ensure that the laboratory meets all the requirements of the relevant standards. Laboratory accreditation is so much more than “just a piece of paper”.

Formal accreditation guarantees many things that you would otherwise need to check if the laboratory didn’t have accreditation. For example, accreditation ensures, amongst other things, that the laboratory fulfills the requirements of the relevant standards, has a quality system and follows it, has appropriate operating procedures, has a training program and training records for staff, can evaluate calibration uncertainty, and maintains traceability to national standards.

Without accreditation you have to take care of all these things yourself, which is a huge task.

Calibration laboratories are commonly accredited according to the international ISO/IEC 17025 standard.

ILAC is the international organization for accreditation bodies operating in accordance with ISO/IEC 17011 and involved in the accreditation of conformity assessment bodies including calibration laboratories (using ISO/IEC 17025).

It is important to remember that accreditation does not automatically mean that the laboratory has sufficient accuracy and uncertainty to calibrate your calibration equipment!

So, even though accreditation is an important box to tick, it is not enough on its own. The burden is still on you to judge the calibration laboratory’s capabilities.

3. Calibration uncertainty

Even when using an accredited calibration laboratory, you need to make sure that the laboratory can calibrate your calibration equipment with sufficient and appropriate uncertainty.

There are many accredited calibration laboratories that do not offer good enough uncertainty to calibrate all the ranges of a modern multifunctional calibrator such as the Beamex MC6 family of calibrators.

If the laboratory is accredited, it will have a public “Scope of Accreditation” document listing all the uncertainties they can offer for different quantities and ranges. That should be evaluated before proceeding further.

If the laboratory is not accredited, you will need to discuss with the laboratory to find out what kind of uncertainty they can offer and if it is sufficient for your needs.

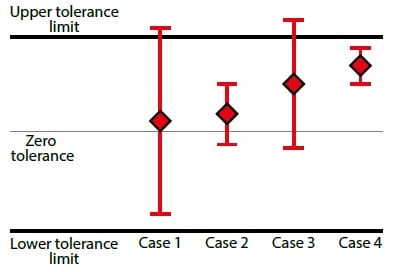

The calibration uncertainty needs to be documented on the calibration certificate. It is then up to you to decide what kind of uncertainty ratio you can accept between the laboratory’s calibration uncertainty and the uncertainty specification of the equipment. The most common uncertainty ratio is 1 to 4, i.e. the laboratory is four times more accurate than the equipment to be calibrated, or the laboratory’s uncertainty is only one quarter of the equipment’s uncertainty. In practice that is often not possible for all ranges, so you may need to accept a smaller uncertainty ratio.

The most important thing is to know the laboratory’s uncertainty, make sure it is better than the equipment’s specifications and ensure it is documented on the calibration certificate.

More information about calibration uncertainty can be found here:

Calibration uncertainty for dummies

4. Calibration certificate

The calibration certificate is the document you get from the calibration, and it should include all the relevant information on the calibration.

Again, if the laboratory is accredited, you don’t need to worry too much about the calibration certificate as an accredited laboratory will follow standards and the calibration certificate content is one of the many audited items included in the laboratory’s periodical accreditation audit.

The basic things on the calibration certificate include:

- The title: “Calibration Certificate”

- Identification of the equipment calibrated

- The calibration laboratory’s contact information

- Identification of the calibration methods used

- Calibration data covering all the calibrated points, i.e. the laboratory’s reference standard’s “true value” and the indication of the equipment to be calibrated

- The found error on each point, i.e. the difference between the reference standard and the calibrated device

- The total calibration uncertainty (presented in the same unit as that of the measurand or in a term relative to the measurand, e.g. percent) including all the calibration uncertainty components, not only the reference standard, preferably calculated separately for each calibration point

- Signature of the person(s) that performed the calibration, the calibration date, and details of the environmental conditions during the calibration process

5. Pass/Fail judgment

When you send your calibration equipment for calibration, you obviously want to know if the equipment fulfills its accuracy/uncertainty specifications. Although this sounds obvious, I have seen customers who have had their equipment calibrated and the calibration certificate archived without evaluating if the equipment is still as accurate as it is assumed to be.

So please make it a practice to carefully review the calibration certificate before filing it away and taking your calibrator back into use.

The Pass/Fail judgment is not all that common in calibration laboratories, accredited or not.

If the certificate does not include the Pass/Fail judgment, it is then your job to go through all the points on the calibration certificate and to compare the found error against the equipment specifications.

The calibration uncertainty also needs to be taken into account in this comparison – the equipment may be within the specifications, but when the calibration uncertainty is taken into account it is not anymore.

So, take a careful look at the found error and the total uncertainty for each calibration point.

There are different ways to take the calibration uncertainty into account in the Pass/Fail judgment. The ILAC G8 (Guidelines on Decision Rules and Statements of Conformity) standard specifies how accredited laboratories should take it into account.

This topic has been discussed in more detail in an earlier blog article:

Calibration uncertainty for dummies – Part 3: Is it Pass or Fail?

6. Adjustment

When the calibration laboratory receives your equipment they will first calibrate all the ranges of the equipment and document the results on the calibration certificate. This is often called the As Found calibration.

But what if the calibration equipment is found to fail at some point(s), i.e. it does not meet its accuracy specifications?

Naturally, the laboratory needs to be able to judge if some calibration points are out of the specifications.

Does the laboratory have the capability, tools, and know-how to adjust the calibration equipment so that all the ranges are within the specifications?

Is the equipment adjusted only if it fails the As Found calibration, or is it also adjusted if there is drift and a risk that it would drift outside of the specifications by the time of the next recalibration?

Most calibration laboratories do not optimize the equipment by adjusting the ranges if they are still within the specifications but have some error. This can cause the equipment to drift out of the specifications and fail before the next recalibration.

Some calibration equipment can be difficult to adjust and may require special tools and knowledge.

If the laboratory is not able to do this kind of adjustment you will need to send the equipment elsewhere, possibly to the manufacturer. This will obviously result in a delay and add costs.

If the laboratory can make the required adjustment, will it mean additional costs for you?

You should find out whether the laboratory can perform the required adjustments before sending your equipment for calibration.

This goes for accredited and non-accredited calibration laboratories alike.

7. As Found / As Left calibration

If the adjustment mentioned in the previous section is done after the As Found calibration, the equipment needs to be calibrated again after the adjustment is done. This is called the As Left calibration.

Will the calibration laboratory perform both As Found and As Left calibrations if necessary?

Are both As Found and As Left calibration included in the calibration price, or do these cost extra?

8. Turnaround time

The turnaround time of the calibration laboratory is another consideration. This also includes the time for transportation both ways.

You don’t want your equipment to be out of service for too long.

9. Brand and reputation

The calibration laboratory’s brand and reputation are also something that will affect the choice you make, especially if you don’t have previous experience of that calibration laboratory.

10.Price

Price is another factor in the selection process.

Don’t just compare prices, but take into account what you will get for that price.

11. Repairs, service, and maintenance

Is the calibration laboratory also capable of performing repairs or other maintenance, if needed?

This also includes firmware updates and other software updates.

12. Warranty

Is the calibration laboratory authorized to do warranty service for your equipment, if it is still under warranty?

Most likely the manufacturer’s warranty is going to be void if some other company services the equipment.

In some cases, using authorized calibration/service centers enables you to extend the warranty of your equipment without additional costs.

Is the calibration laboratory’s work covered by some kind of warranty?

13. Agreements and reminders

Does the calibration laboratory offer the possibility to make a continuous agreement for future calibrations?

Will the calibration laboratory send you a reminder when it is time for the next calibration?

Download this article as a free pdf file by clicking the picture below:

What do we do at the Beamex calibration laboratory?

The Beamex factory calibration laboratory in Finland has been ISO 17025 accredited since 1993 and serves as the standard for the Beamex USA calibration laboratory with over 30 years of experience in calibrations and repairs.

Since our factory manufacturing facilities are in the same location as the calibration laboratory, we have a very good set of laboratory equipment and automated calibration systems that minimize the risk of human error. It would not be realistic to have that kind of equipment only for recalibration purposes.

Please note that we currently only recalibrate Beamex manufactured devices.

Here is a short list of the things that we do at the Beamex factory calibration laboratory when we get a calibrator back for recalibration:

When a unit is received, it is properly cleaned and any minor service needs are taken care of.

The unit is then calibrated (As Found) and an accredited calibration certificate is created.

If the unit fails in some ranges, these range are adjusted; if the unit does not fail but there is some minor drift, the unit will be adjusted to improve its accuracy. If a unit passes but is close to its specification limits, it is adjusted to help prevent it drifting out of specifications by the time of the next calibration.

If any ranges are adjusted, a new As Left calibration will be carried out.

Most of the calibration work is automated, so we can offer fast and reliable service.

Finally, the firmware of the unit as well as any device description files are updated if needed.

Here's a short video on our recalibration services:

Here's a short video on our calibration laboratories:

Beamex Care Plan

We offer a Care Plan agreement for the calibrators we manufacture.

Care Plan is a contract for the recalibration and maintenance of Beamex equipment, ensuring the equipment stays accurate and operational throughout its lifetime.

A Beamex Care Plan includes the following services:

- A fixed-term contract (one or three years) – a single purchase order reduces unnecessary admin work and associated costs

- Annual recalibrations with an accredited calibration certificate (including As Found calibration, any necessary adjustments, and As Left calibration)

- Free express shipments to and from the Beamex factory

- Free repairs, even in the case of accidental damage

- Replacement of wear parts

- Annual email notification when a calibration is due – allows you to schedule your recalibration needs around any potential outages

- Applicable updates of firmware, device description files, and so on, ensuring your device has the latest features

- Priority help-desk services

- Priority service – expedited turnaround times

Learn more about the Beamex Care Plan.

Here's a short video on our Care Plan agreement:

Beamex Service Portal

The Beamex Service Portal is an easy way for you to request a quote or return your Beamex equipment for service or calibration.

Learn more about the Beamex Service Portal.

.jpg)

.png)

Discussion