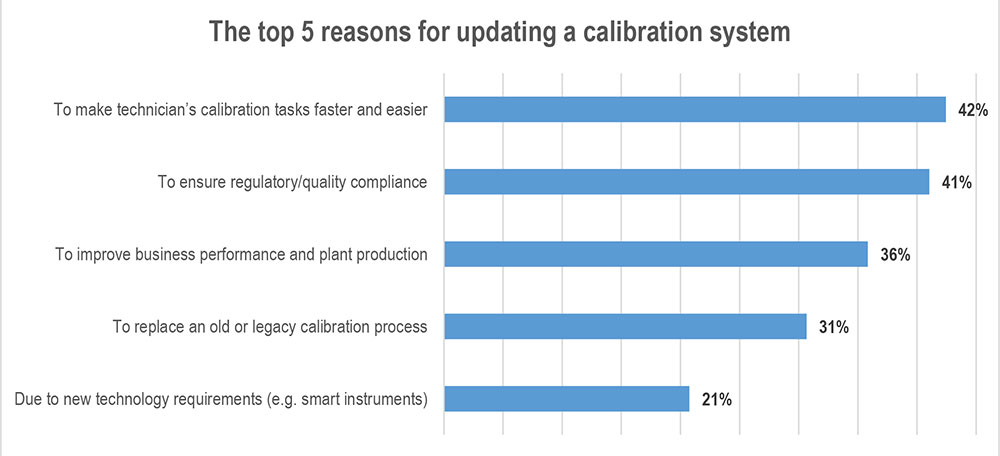

Figure 1. Top 5 reasons for updating a calibration system. Results from a study concerning calibration process change, conducted by Beamex and ISA in 2015.

Figure 1. Top 5 reasons for updating a calibration system. Results from a study concerning calibration process change, conducted by Beamex and ISA in 2015.So, why do companies plan or decide to update their calibration processes? By an update in the calibration process I mean, in this context, making a change in the tools, systems and work procedures for performing, documenting and managing calibration of process instruments. Any change must of course happen for a reason. Most likely the reason is a challenge or problem in the current way of doing things that the company wants to fix. If there’s no problem, there’s no clear reason or justification to update anything. So what are the top five reasons or problems causing calibration process updates?

The most common reason why companies decide to update their calibration systems is to make technicians work faster and more efficient. 42 % of companies state this as one of the key reasons to implement changes in their calibration processes. The key reason is therefore related to gaining economic and productivity efficiency through making a change in the calibration system.

Almost as many people state that the key reason for making a change is to ensure compliance with regulatory and quality requirements. The return on investment of compliance is maybe more difficult to calculate compared to calculating time-savings of a calibration engineer between current and new calibration processes, but you can always ask yourself: what is the price of non-compliance? Ultimately, non-compliance could even mean shutdown of a manufacturing site by a regulatory authority, and we can all understand what kind of economic impact that would have on a business.

The third most common reason for making a process change is to improve business performance and plant production. Again, gaining economic and productivity efficiency is at the heart of a process change, but now the reasons are maybe even on a broader scale, to improve plant- or even company-level performance through smarter calibration.

The fourth most common reason to implement a process change is to replace and old and outdated legacy system. Instead of just gaining economic or compliance improvements, companies are therefore also “forced” to update their calibration systems based on technological necessities and risks, such as managing currently calibrations with software that is not supported or maintained anymore with new releases. The fifth most common reason is also technology-related, as companies also decide to update their calibration processes due to new technological requirements, such as smart instruments being used at a manufacturing site.

As said, every change requires a reason and the reason is often in the form of a problem or challenge that requires fixing. The top five reasons for making a calibration process change are economical, compliance and technology related. So what’s your problem? What would drive you to make a calibration process change? Also, would you like to learn what the areas are where companies most often need help when making a calibration system and process update? Let me know :)

Regards,

Villy

Villy Lindfelt is Director of Marketing & Legal Affairs at Beamex Oy Ab.

He supervises the marketing team as well as focuses on contracts and documentation, related to calibration system implementation projects. Villy started working for Beamex in 2004 and has since then been surrounded by bright people who have thought him a thing or two about calibration and implementing calibration systems. He has a Master’s degree in Economics as well as a Master of Laws degree. Villy's family consists of himself, his wife and their two daughters.

.jpg)

Discussion