The digitalization of metrology has been slower than in many other fields, and calibration processes in many industries are still mostly paper based.

But that's about to change!

Enter the Digital Calibration Certificate (DCC), “the MP3 of metrology”. Just as the MP3 revolutionized the music industry, the DCC has the potential to revolutionize the process industry by enabling electronic storage and sharing of calibration results in a standardized, consistent, authenticated, and encrypted manner.

No more struggling with manual interpretation of paper certificates! With the DCC, calibration data is machine-readable and easily imported into your system. A DCC is created using digital signatures and encryption methods to ensure its authenticity and integrity, and it's compatible with international standards, making it easy to share with calibration laboratories, manufacturers, and users of measuring instruments.

But that's not all! The DCC has a ton of benefits, like increased transparency, efficiency, and traceability in the calibration process, as well as reduced costs and time. And the best part? A team of key players, including Beamex, is working on creating a global DCC standard so you won't have to worry about compatibility issues.

If you thought that a PDF is a digital calibration certificate, think again!

So, if you're in the process industry, keep calm and get ready to adopt the DCC! It could be the game-changer you've been waiting for.

Download the full article in pdf format >>

Table of contents

- Background

- Processes with paper certificates

- Digital Calibration Certificate (DCC)

- The main benefits of the Digital Calibration Certificate (DCC)

- An emerging global standard

- Keep calm and adopt the DCC!

- Interested in learning more?

- Relevant material & links

- Related blogs

Background

Metrology is a crucial aspect of modern industrial activity as it involves measuring and ensuring the accuracy of physical quantities.

However, the digitalization of metrology has been slower than that of other industries, with calibration processes still being mostly paper based. This means that processes relying on metrological data are often manually executed by humans, which can be slower and more prone to errors compared to machine-to-machine communication.

The growing gap between the digitalization of the process industry and the calibration industry is creating a significant discrepancy in terms of efficiency, productivity, and quality. While the process industry is using advanced technologies such as automation, artificial intelligence, and data analytics to optimize its operations and achieve higher levels of productivity and quality, the calibration industry is lagging behind in terms of digitalization.

To address this issue, a digital calibration certificate (DCC) is being developed to enable electronic storage and sharing of calibration results in an authenticated and encrypted manner.

The DCC even enables machine-to-machine communication so that calibration results can be transferred directly from the calibration equipment to the relevant systems without the need for manual intervention.

This may sound futuristic, but even the current Beamex paperless calibration ecosystem works so that a documenting calibrator (such as a Beamex MC6) automatically saves the calibration results digitally in its memory after calibration. From the calibrator’s memory that digital file is then transferred to calibration management software (Beamex LOGiCAL or CMX) for storing and analysis. That calibration results file is still in Beamex's proprietary format.

The DCC also facilitates sharing calibration data among different stakeholders - for example, external calibration service providers (calibration labs, producers of calibration data) and industrial end-customers (consumers of calibration data). This digitalization and automation reduces the likelihood of errors, improves efficiency and enables almost real-time data integration for improved decision-making.

This would result in more consistent interpretation of the results and improved traceability, as well as enable proper data analytics in process industries and the creation of digital twins for testing and improving processes. This could ultimately lead to increased efficiency, improved safety, cost savings, and new business models.

Beamex has actively participated from the beginning - working alongside Physikalisch-Technische Bundesanstalt (PTB), the national metrology institute of Germany - in creating a globally recognized Digital Calibration Certificate (DCC) format. Our expertise has been instrumental in shaping the DCC standard to meet the specific needs of the process industry. We are preparing to incorporate the DCC into our products to ensure they are future-proofed.

Being entrusted with this significant responsibility by key stakeholders, including PTB, is a true honor. With our extensive experience in delivering digital calibration solutions, we have established ourselves as a crucial player in this field. We take great pride in leading the development of the DCC and remain dedicated to making it applicable and beneficial for the process industry. The recognition and trust from other stakeholders involved in the DCC initiative further reinforces our commitment to this important endeavor.

Processes with paper certificates

When a company sends their calibrator or reference standard to an accredited calibration laboratory, they typically receive the equipment back with a paper calibration certificate. This certificate is then stored somewhere or scanned and saved as a file.

If the company wants to run analytics on the certificate, or make a history analysis on several certificates, they need to manually enter each calibration point data into a software to do that. That is because the paper certificate is not standardized neither machine-readable.

In the near future, Digital Calibration Certificates will be delivered as a standardized machine-readable, authenticated, and encrypted files, that can be imported into the company’s system.

Digital Calibration Certificate (DCC)

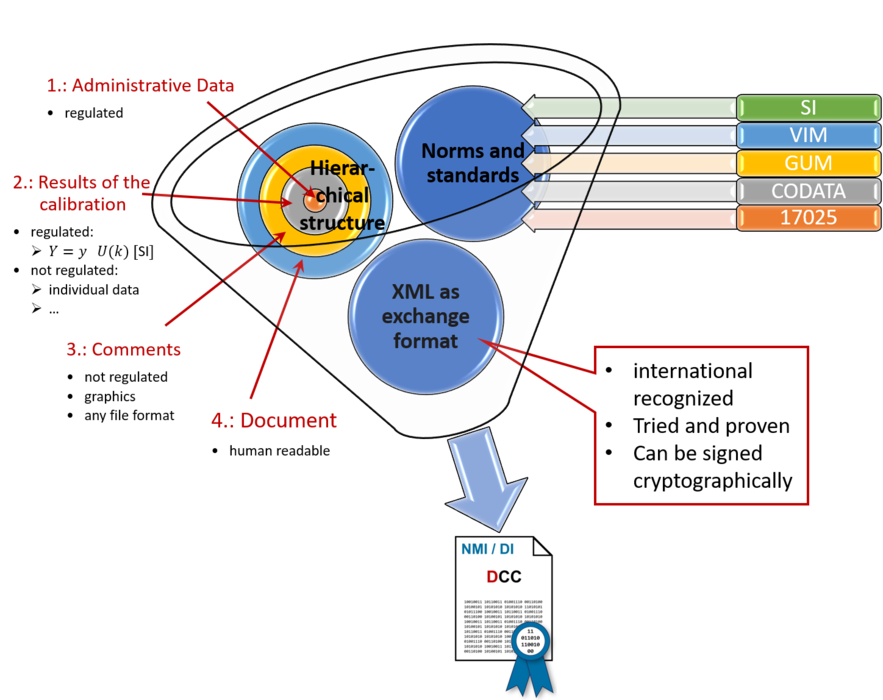

Basically, the DCC is intended to become a globally standardized format for calibration data defined in the form of an XML (Extensible Markup Language) schema.

When a calibration laboratory performs a calibration, it creates the DCC file and adds all calibration-relevant data to the file. This file is then delivered to the customer. When receiving the file, the customer can have it automatically imported into their own system, thanks to the standardized format of the DCC file.

The DCC contains all relevant calibration data, including the date of the calibration, the calibration method used, the measurement uncertainty, and the results of the calibration.

The DCC is created using digital signatures and encryption methods to ensure its authenticity and integrity. It can be accessed and shared online, making it easily accessible for calibration laboratories, manufacturers, and users of measuring instruments.

The main benefits of the DCC include increased transparency, efficiency, and traceability in the calibration process, as well as reduced costs and time.

The DCC is also compatible with international standards and can be used for both national and international calibration requirements.

The XML structure of DCC:

Image copyright by Physikalisch-Technische Bundesanstalt (PTB). All rights reserved.

The main benefits of the Digital Calibration Certificate (DCC)

Here is a short summary of the benefits of the DCC. For the full list, please download the White Paper.

- DCC makes it easier to analyze calibration data and create digital twins that help improve efficiency and safety in the process industry.

- DCC supports digital transformation by allowing contractors and labs to easily connect to a digitized calibration system with centralized management.

- DCC uses a standardized approach to data entry, making it easier to compare and harmonize data from different sources.

- DCC makes it easy to manage and search for calibration data and instrument devices, even for large-scale operations.

- DCC enables preventive maintenance by alerting when instruments need checking instead of relying on fixed intervals, leading to better risk-based approaches to maintenance and calibration.

- DCC increases traceability by replacing inefficient paper-based processes with easy digital search capabilities.

- DCC is flexible, allowing customers to use their preferred calibration processes and still generate easily shareable and searchable digital certificates.

- DCC is secure, with cryptographic protection to ensure authenticity and data integrity.

Another source discussing the DCC benefits is the Benefits of network effects and interoperability for the digital calibration certificate management by the 2021 IEEE International Workshop on Metrology for Industry 4.0 & IoT.

An emerging global standard

Efforts are happening right now to create a global DCC standard. A team of key players, including Beamex, is working together to define requirements, create guidelines and software, and promote awareness and training.

This DCC meets the requirements of DIN EN ISO/IEC 17025:2018-03. The Gemimeg II project is currently leading the way in DCC development, thanks to investments from the German government and involved companies.

Another project, SmartCom, was focused on improving the traceability and handling of metrological data through the creation of DCC with set standards.

In addition, other projects and initiatives have also been taking place to enable the uptake of DCC to improve the traceability and handling of metrological data.

Such projects include for example EMPIR 17IND02 SmartCom, EURAMET TC-IM 1448, and Digital NIST.

Together, these initiatives are building a DCC standard that is already being tested in industrial applications.

Due to their key role in the metrology infrastructure, the National Metrology Institutes (NMIs) will also play an important role in ensuring widespread adoption of the DCC standard.

Keep calm and adopt the DCC!

The DCC has the potential to transform the process industry. Instead of relying on error-prone and labor-intensive paper-based processes, digital calibration data could be easily searched, shared, and analyzed. This would not only make audits more efficient, but it could also allow data to be used to create digital twins of processes to find efficiency and safety improvements.

At Beamex, we have been digitalizing calibration processes for over 40 years and we see the DCC as a natural extension of these efforts. We believe that cooperation between standards-setting institutions, labs, vendors, and major players in the industry will be needed to make the DCC happen.

That's why we are keen to encourage other industry players to join us in these initiatives and contribute to supporting the implementation of the DCC across industries.

At Beamex we have run several successful proof of concept projects with the DCC and have seen that the DCC is really working in practice.

When you choose Beamex, you are choosing a future-proof solution that is ready to support digitalization efforts and make processes safe, secure, and efficient. Our products are designed to be compatible with whatever DCC standard evolves.

Interested in learning more?

If you want to learn more about the DCC or discuss with our experts, please feel free to book a discussion with them:

In LinkedIn, feel free to connect and discuss with me or with my colleagues with expertise in DCC:

- Sami Koskinen, Director of Digital Transformations

- Jan-Henrik Svensson, CEO Beamex Group

- Antonio Matamala, Director of Sales, Beamex GmbH

- Tuukka Mustapää, Requirements Specialist on DCC

Download the full article here:

Relevant material & links

Documents describing the basic concept and overall structure of the DCC:

- S. Hackel, F. Härtig, J. Hornig, and T. Wiedenhöfer. The Digital Calibration Certificate. PTB-Mitteilungen, 127(4):75–81, 2017. DOI: 10.7795/310.20170403.

- S. Hackel, F. Härtig, T. Schrader, A. Scheibner, J. Loewe, L. Doering, B. Gloger, J. Jagieniak, D. Hutzschenreuter, and G. Söylev-Öktem. The fundamental architecture of the DCC. Measurement: Sensors, 18:100354, December 2021. DOI: 10.1016/j.measen.2021.100354.

Additional information on the technical aspects of DCC can also be found on the PTB’s Digital Calibration Certificate Wiki: Digital Calibration Certificate (DCC) - Wiki | Digital Calibration Certificate - Wiki (ptb.de)

Further reading on the potential and benefits of the DCC in a calibration ecosystem:

- J. Nummiluikki, T. Mustapää, K. Hietala, and R. Viitala. Benefits of network effects and interoperability for the digital calibration certificate management. 2021 IEEE International Workshop on Metrology for Industry 4.0 & IoT. DOI: 10.1109/MetroInd4.0IoT51437.2021.9488562.

- J. Nummiluikki, S. Saxholm, A Kärkkäinen, S. Koskinen. Digital Calibration Certificate in an Industrial Application, Acta IMEKO Vol. 12, No. 1 (2023). DOI: 10.21014/actaimeko.v12i1.1402.

Related blogs

If you liked this article, you might like these ones too:

- Calibration management - transition from paper-based to digital

- Calibration in Times of Digitalization - a new era of production

- Data Integrity in Calibration Processes

- Calibration Management and Software [eBook].

.png)

.jpg)

Discussion