This is the first blog post in the Beamex blog series "Calibration in Times of Digitalization" we will take a look into the future to give you an understanding of hot topics such as Industry 4.0 and Smart Factory, which are on everyone's minds.

You have probably heard of terms such as Digitilization, Industry 4.0 and Smart Factory. But what do these really mean? Many users of these new technologies don’t yet fully grasp them. This is completely understandable and that's why we will gradually bring you closer to these topics in this Beamex blog series and help you enter the future well informed.

Whether on television, in newspapers or on social media, hardly a day goes by without futuristic topics such as digitalization, big data, artificial intelligence and machine learning. But futuristic? Hasn't the future already arrived?

What will tomorrow's process industry look like?

Almost everyone today owns a smartphone that, without being aware of it, is equipped with a variety of sensors and communication technologies. Worldwide, there are now 5.1 billion users of mobile devices and the number is growing at an annual rate of 4%. Whether with a smartphone or directly on your computer, you are most likely a private individual who purchases comfortably from your sofa at home and are hardly surprised if underneath the product you have selected on the website says "Customers who bought this product were also interested in this product." At home, the future seems to have made its way long ago. Behind these platforms hide exactly those technologies that have made your private life easier and more convenient, and these exact technologies are currently making their way into the process industry within the framework of Industry 4.0. But now please ask yourself the question, what does your work environment look like? Are you still working with outdated technologies, or are you now also seeing a wave of modernization on the horizon?

The fact is, many employees are worried about terms such as machine learning, robotics and smart factories and what will happen tomorrow. You may also be afraid your future colleagues will be made of metal and make "blip" noises like in the award-winning Star Wars series. Or you have the idea that in the future you will hardly meet any people on the shop floor. To take away at least some of these worries in advance, the industrial production of tomorrow, and thus the factory of the future, will rely much more on the latest information and communication technologies than it does today. And no, the "factory of the future" cannot be imagined without people. They will even play a very important role. This should be reassuring, and it is, but there is a good chance that things will change in your environment in the future. Because digital technologies in modularly organized plants of the future will make processes flexible, the maintenance of such machines will be equally affected, as will the calibration of the growing number of process sensors that make Industry 4.0 possible in the first place. In other words, the digital factory will automatically lead to digital maintenance. And that could happen faster than you think.

So you should start to proactively prepare for a digital future, starting by getting a picture of what will change. Because the way we work in maintenance today will change. That's for sure! But what we can tell you in advance: If you work in a calibration environment, then your work will gain in importance!

How exactly which factors will play a role in the future will be explained step by step in this and other blogs. It is important that you first understand the technologies and important interrelationships that lie at the basis of these digital changes that you have probably already experienced through a wide variety of media channels.

Leaving the comfort zone step by step

There are trends and you should accept if you can't stop them. For example, when the first computers came onto the market, the then CEO of one of the leading technology companies made a forecast: "I think there's a world market for maybe five computers.” Maybe you're smiling while reading it because this forecast seems completely absurd to you. But at the beginning of the computer industry, nobody really knew where this new technology would take us. But the explosion of desktop computing has changed our lives a lot. And even if you think that the role of a computer in your private environment is limited, in our modern society nothing would work without computers. By the way, the same applies to the role of the Internet in our society. Was it not then to be expected that computers and above all Internet technologies would sooner or later find their way into the process industry?

In the Industry 4.0 era, production is closely interlinked with information and communication technologies, making it more flexible, efficient and intelligent. There is even talk of batch size 1, which might perhaps cause a question mark rather than an "A-ha" effect on you. Well, it's quite simple: with the expectation to meet the ever faster and more comprehensively changing customer requirements, customers expect individualized products that meet their requirements, but at prices that only series production can offer. How is that supposed to work? The answer is Industry 4.0.

Industry 4.0 has set itself this goal and offers a variety of concepts, guidelines and technologies for building new factories or retrofitting existing ones, which, thanks to modular production lines equipped with flexible automation, IT and communication technologies, make it possible for customers to choose from a variety of variants at series production prices. In addition, the interconnection of the value chain extends far beyond the manufacturing company. The entire value chain, including suppliers, is also to be connected horizontally. Connectivity even goes one step further: thanks to connectivity, products that leave the factory should also report regularly to the manufacturer, e.g. for maintenance, and report on their status.

Nevertheless, there are big differences between the time when this already mentioned CEO ventured to forecast the world computer market and the present time. Although the term Industry 4.0 - meaning the fourth industrial revolution - today causes similar social uncertainties as computers did at that time, it is decisive for the future of the process industry, especially for the manufacturing industry. Where the computer was a fundamental new technological invention, Industry 4.0 consists of composite technological components, some of which already exist as modules, but interoperability for fast and flexible "plug & play" deployment is still in its infancy. It should be noted that the first three industrial revolutions (1. steam engine, 2. assembly line , 3. automation and IT) were only subsequently classified and recognized as revolutions. In contrast, the so-called 4th Industrial Revolution is more like a controlled process, which from today's point of view takes place in the near future and is currently in the process of unfolding.

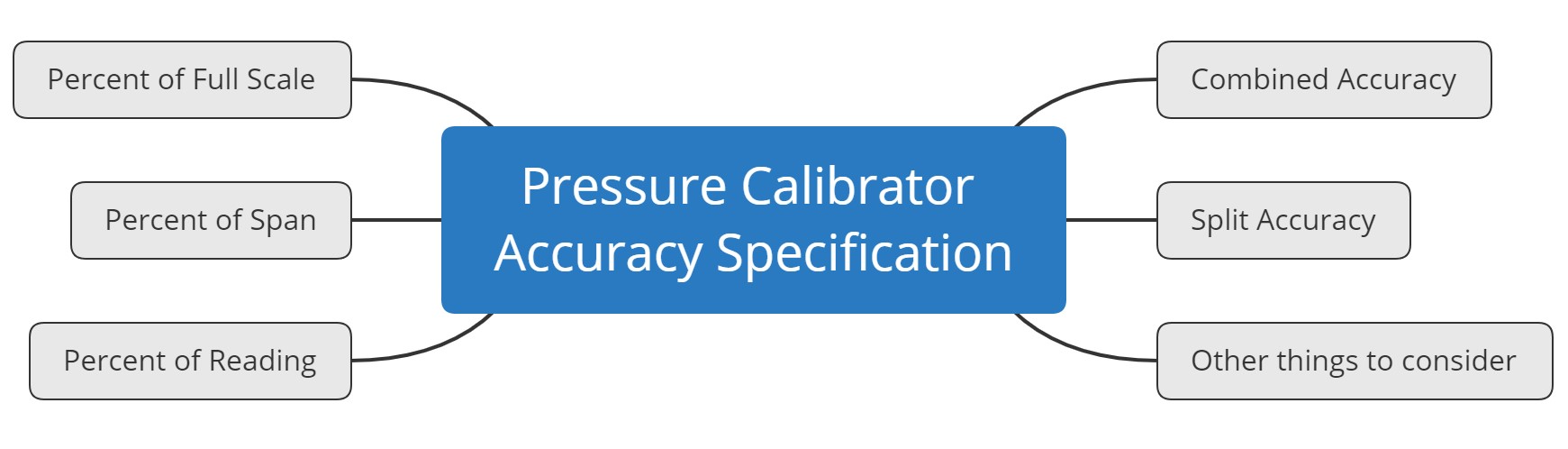

Sensors as key technology

The fact that Industry 4.0 is more like a controlled process than a wild revolution is of great benefit to many participants, even though it is not possible to say exactly where the journey will lead. What we can predict, however, is that tomorrow's world will be much more digital than it is today, and that will certainly affect your work as process workers, both in production and maintenance. If you are working in calibration, the following may be particularly important to you. For the factory of the future to exist at all, smarter objects (whether machines or end products) will need to be used to orchestrate manufacturing processes according to Industry 4.0 objectives. Objects without sensors are blind and unfeeling and can neither see how they have to act in connection with other modules nor can they report their own condition to top-level systems about, for example, the need for timely and optimized maintenance to prevent costly system failures.

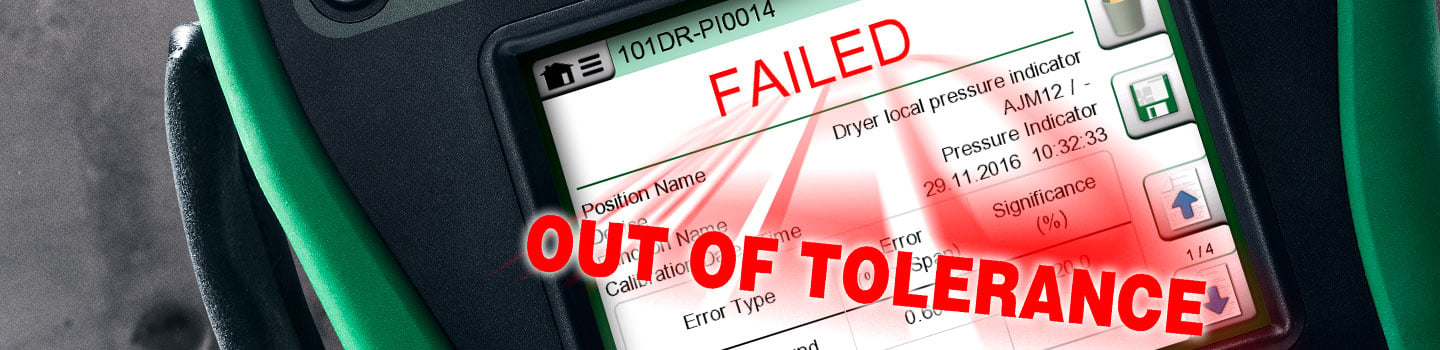

Sensors therefore play not only an important, but an essential role in the implementation of Industry 4.0. They form the interface between the digital and the real world. Data generated by these sensors must be correctly interpreted for further processing, and they must always be of excellent quality! Industry 4.0 also means that, in the future, sensors will be used far beyond the actual production processes. They also play a role in upstream, downstream and parallel sub-processes, such as predictive maintenance. One could therefore say that without the right sensors, all higher-level systems are blind, and with incorrect measurement data, wrong decisions are made. What should hardly surprise the maintenance staff is that the data quality of measurement data is based on a professional and prompt calibration of the sensors.

In the next blog we continue explaining the role of sensors and other technologies in Industry 4.0 and how these may affect your daily work.

Download the free white paper by clicking the picture below:

About Beamex

Beamex has set itself the goal to find a better way to calibrate together with its customers. This also means taking a leading role in digitilization and Industry 4.0. If we have aroused your interest after reading this article, we would like to discuss this topic with you. We are very interested in exploring your current business processes regarding calibration to provide you with concepts for a better calibration in the digital era.

.png)

.jpg)

Discussion